That sinking feeling when your diesel starts pushing coolant, running rough, or showing white smoke is something no equipment owner wants to experience. At FridayParts, we’ve seen thousands of failed cylinder heads come through our doors over the past 16 years, and the damage patterns tell a story – usually one of preventable failure. Whether you’re dealing with a warped head that won’t seal or severe pitting that’s eating through material, understanding what causes these failures can save you from a $3,000-10,000 repair bill. Let’s dive into the real reasons cylinder heads fail and, more importantly, how you can prevent your engine from becoming another casualty.

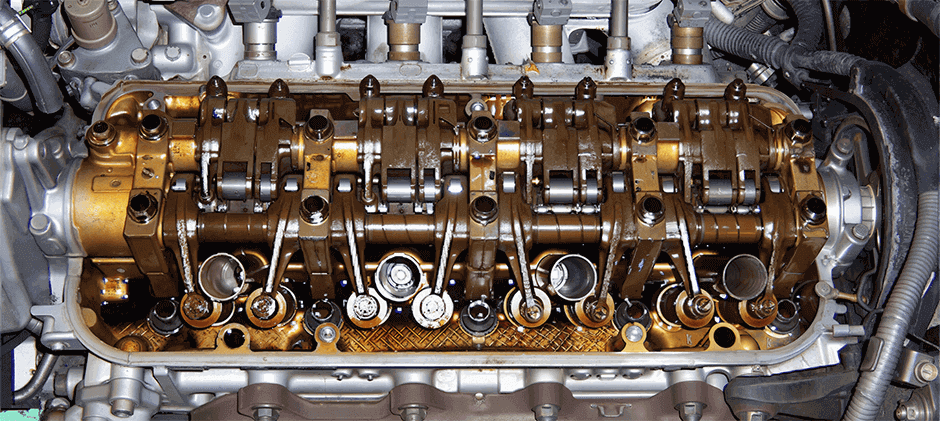

1. Overheating: The Number One Head Killer

If cylinder head failure had a most wanted list, overheating would have its mugshot at the top. Heat is the arch-enemy of cylinder heads, especially aluminum ones, and even a single overheating event can cause permanent damage.

How Overheating Destroys Heads:

When your engine overheats, several destructive processes kick into gear:

- Aluminum heads can reach their elastic limit at just 400-450°F

- The head expands faster than the block, creating massive stress

- Hot spots develop, causing localized warping

- Thermal shock from rapid cooling creates cracks

- Extreme heat breaks down the metal’s grain structure

The Warping Process:

Picture your cylinder head as a long, flat piece of metal being heated unevenly. The hottest areas (usually between exhaust valves) expand more than the cooler areas. Since the head bolts keep it clamped down, this expansion has nowhere to go but up, creating the classic “bowed” warp pattern we see so often.

“I’ve measured heads that were warped 0.015 inches after just one overheating episode,” shares a machine shop owner. “The customer drove only five miles with a blown radiator hose, but that was enough to turn a 50hosereplacementintoa50 hose replacement into a 50hosereplacementintoa2,500 head job.”

Common Overheating Causes:

- Coolant leaks are going unnoticed

- Failed water pump

- Stuck thermostat

- Clogged radiator

- Blown head gasket (creates a vicious cycle)

- Excessive load in hot conditions

- Fan clutch failure

The Damage You Can’t See:

Even if a head looks straight, overheating causes invisible damage:

- Valve seats loosen or fall out

- Guides lose their press fit

- Hardness changes make the head soft

- Micro-cracks form and grow over time

2. Combustion Gas Erosion and Pitting

When head gaskets begin to fail, they rarely go quietly. Instead, they create a destructive force that eats away at your cylinder head like acid, because in a way, that’s exactly what’s happening.

The Erosion Process:

Combustion gases escaping past a failing gasket create several problems:

- Temperature: 1,500°F+ gases directly contact aluminum

- Pressure: High-pressure jets cut through metal like a torch

- Chemistry: Combustion byproducts are corrosive

- Velocity: Gas flow creates erosion like water on rock

Why Pitting Develops:

The combination of heat, pressure, and corrosive gases creates perfect conditions for pitting:

- Initial gasket failure creates a small leak path

- Hot gases begin eroding metal

- Erosion creates a larger leak path

- Increased flow accelerates damage

- Deep pits form that can’t be repaired

“Fire slot erosion is what we call it,” explains a diesel technician. “Once combustion gases find a path, they’ll cut through aluminum like a plasma cutter. I’ve seen heads with channels eroded half an inch deep in just 10,000 miles of driving with a blown gasket.”

Common Pitting Locations:

- Between cylinders (narrowest material)

- Around fire rings

- Near coolant passages

- Between valves

- At the deck surface edges

The Point of No Return:

Minor pitting (less than 0.030″ deep) can sometimes be repaired with:

- Furnace welding and remachining

- Epoxy repairs (temporary)

- Spray welding processes

But deep pitting means replacement because:

- Structural integrity is compromised

- New gaskets won’t seal

- Repair costs exceed replacement

- Pits often extend into ports

3. Incorrect Torque and Installation Procedures

More cylinder heads and cylinder components are killed in the shop than on the road. Improper installation procedures, especially incorrect torque, create problems that doom the head from day one.

Why Torque Matters So Much:

Cylinder head bolts don’t just hold parts together – they create precise clamping loads that:

- Seal the head gasket properly

- Distribute stress evenly

- Allow for thermal expansion

- Prevent combustion gas leakage

- Maintain valve train geometry

Common Torque Mistakes:

- Under-torquing: Insufficient clamping = blown gaskets

- Over-torquing: Distorts head and strips threads

- Wrong sequence: Creates uneven stress and warping

- Dirty threads: False torque readings

- Reusing TTY bolts: Already stretched bolts can’t clamp properly

- Missing steps: Many engines require angle torquing

The Warping Cascade:

Incorrect torque creates immediate problems:

- Uneven clamping distorts the head

- Distortion prevents proper gasket sealing

- Leaking gases create hot spots

- Hot spots cause more warping

- Increased warping accelerates gasket failure

“I trained a new tech who thought more torque was better,” recalls a shop foreman. “He cranked head bolts to 150 ft-lbs instead of 110. The head was warped 0.008 inches before the engine even started. That’s an expensive training mistake.”

Proper Installation Requirements:

- Clean, dry threads (unless specified otherwise)

- Calibrated torque wrench

- Correct torque sequence (usually center-out spiral)

- Multiple stages (30%, 60%, 100%)

- Angle gauge for TTY bolts

- Retorque after heat cycling (if required)

The Technology Factor:

Modern engines are less forgiving:

- Lighter construction means less margin for error

- MLS gaskets require precise clamping

- Aluminum heads distort more easily than iron heads

- Four-valve heads have complex stress patterns

4. Coolant System Contamination

Your coolant is supposed to protect your engine, but when it goes bad, it becomes a cylinder head destroyer. Contaminated coolant causes more slow-motion head cylinder failures than almost any other factor.

How Coolant Attacks Heads:

- Corrosion: Acidic coolant eats aluminum

- Electrolysis: Electrical current erodes metal

- Cavitation: Bubble implosion pits surfaces

- Scale: Deposits create hot spots

- Erosion: Flow washing wears passages

The Chemistry of Destruction:

When coolant breaks down:

- pH drops below 7 (becomes acidic)

- Protective additives get depleted

- Metals go into solution

- Silicates drop out and form deposits

- Electrical conductivity increases

Contamination Sources:

- Combustion gases: From blown gaskets

- Oil: Creates sludge and acids

- Air: Oxidation ruins coolant chemistry

- Hard water: Minerals create scale

- Wrong coolant: Mixing types creates gel

- Exhaust gases: EGR cooler failures

“I’ve torn down engines where the coolant passages looked like cave formations,” describes an engine rebuilder. “Years of neglected coolant created so much scale that the coolant couldn’t flow. The heads were pitted through in multiple places.”

The Electrolysis Problem:

Modern engines with aluminum heads and iron blocks create a battery:

- Dissimilar metals in the electrolyte (coolant)

- Electrical current flows between components

- Aluminum erodes rapidly (sacrificial anode)

- Pitting develops at electrical grounds

- Can eat through the head in months

Prevention Strategies:

- Test coolant pH annually

- Change per the manufacturer’s schedule

- Use the correct coolant type

- Fix leaks immediately

- Check for electrical grounds

- Flush the system properly

- Use distilled water only

5. Detonation and Pre-ignition Damage

While diesel engines don’t spark knock like gas engines, they can experience destructive detonation and pre-ignition that hammer cylinder heads into submission. This abnormal combustion creates pressure spikes that exceed design limits.

Understanding Diesel Detonation:

In a properly running diesel:

- Fuel burns progressively

- Pressure rises smoothly

- Peak pressure stays within limits

During detonation:

- Multiple flame fronts collide

- Pressure spikes dramatically

- Shock waves hammer components

- Temperatures skyrocket locally

What Causes Diesel Detonation?

- Over-advanced injection timing

- Poor fuel quality or contamination

- Excessive boost pressure

- Lean fuel mixture under load

- Carbon buildup creates hot spots

- Incorrect injector spray pattern

- EGR system malfunctions

The Damage Pattern:

Detonation damage is distinctive:

- Pitting between valves

- Eroded fire rings

- Cracked combustion chambers

- Valve seat recession

- Localized melting

- Gasket failure at the specific head cylinder

“Detonation damage looks like someone went after the head with a ball-peen hammer,” explains a performance diesel builder. “The pressure spikes can exceed 3,000 PSI – way beyond what any head is designed for. I’ve seen heads cracked right through the valve seats.”

Pre-ignition vs Detonation:

- Pre-ignition: Combustion starts too early

- Detonation: Abnormal combustion after normal ignition

- Both create destructive pressure spikes

- Often occur together

- Damage patterns similar

Contributing Factors:

- Modified engines pushing limits

- Poor quality tuning

- Inadequate cooling

- Wrong fuel cetane rating

- Boost leaks causing lean spots

6. Thermal Cycling Fatigue

Every time your diesel starts cold and warms up, the cylinder head goes through a stress cycle. After hundreds of thousands of these cycles, even good heads can develop fatigue cracks. It’s like bending a paperclip back and forth – eventually, it breaks.

The Stress Cycle Explained:

During each heat cycle:

- Cold start: The Head is contracted

- Warm-up: Rapid expansion begins

- Uneven heating: Different areas expand at different rates

- Operating temp: Maximum expansion

- Shutdown: Contraction begins

- Cool down: Return to contracted state

Why Cylinder Head Cracks from Cycling:

- Aluminum expands 2x more than iron

- Constrained by head bolts

- Stress concentrates at weak points

- Repeated stress creates micro-cracks

- Cracks propagate with each cycle

High-Risk Areas:

- Valve bridges: Thinnest material, highest temps

- Injector ports: Stress risers from machining

- Exhaust ports: Maximum thermal gradient

- Water jacket corners: Sharp corners concentrate stress

- Bolt bosses: High clamping loads

“Thermal fatigue is the silent killer,” notes a fleet maintenance manager. “An engine can run perfectly for 500,000 miles, then suddenly develop cracks everywhere. It’s not abuse – it’s just metal fatigue from millions of heat cycles.”

Accelerating Factors:

- Short trips (more cycles per mile)

- Cold climate operation

- Frequent idle periods

- Load variations

- Coolant temperature fluctuations

- Poor warm-up habits

Design Evolution:

Modern heads resist fatigue better through:

- Improved alloys

- Better casting techniques

- Reinforced critical areas

- Optimized coolant flow

- Reduced stress concentrations

But they still fatigue eventually!

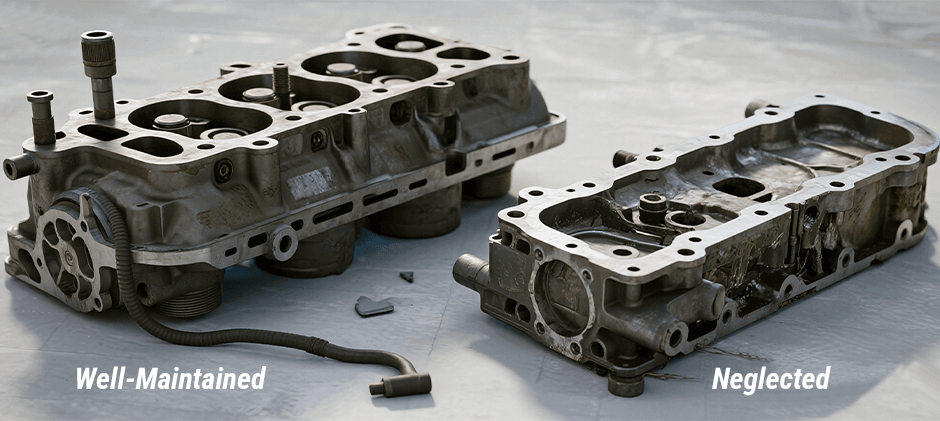

7. Poor Maintenance Practices

Sometimes cylinder heads fail not from one catastrophic event, but from death by a thousand cuts – poor maintenance that accumulates into major damage over time.

The Neglect Cascade:

How small issues become head failures:

- Skipped oil changes → Sludge buildup → Clogged oil passages → Valve train wear → Head damage

- Ignored coolant service → Corrosion → Pitting → Leaks → Overheating → Warped head

- Deferred repairs → Small problems → Bigger problems → Catastrophic failure

Common Maintenance Failures:

Cooling System Neglect:

- Never changing coolant

- Ignoring small leaks

- Running low on coolant levels

- Not cleaning radiator fins

- Ignoring temperature gauges

Oil System Issues:

- Extended oil change intervals

- Wrong oil viscosity

- Cheap filters

- Low oil level operation

- Ignoring oil consumption

Air System Problems:

- Clogged air filters

- Boost leaks ignored

- Intercooler never cleaned

- Turbo maintenance skipped

“I see it all the time,” shares a diesel shop owner. “Customer saves 50onacoolantflush,thenspends50 on a coolant flush, then spends 50onacoolantflush, then spends 5,000 on a head job two years later. The worst part? The old coolant was like chocolate milk – they knew it needed changing.”

The Documentation Problem:

Poor maintenance often means:

- No service records

- Unknown history

- Previous repairs unknown

- Problems compound unseen

- Warranty claims denied

Real Cost of Neglect:

Skipping $500 annual maintenance leads to:

- Premature head failure

- Complete engine damage

- Downtime costs

- Lost resale value

- No failure warning

8. Manufacturing Defects and Design Issues

Not all head failures are the operator’s fault. Some cylinder heads have inherent design flaws or manufacturing defects that make failure almost inevitable.

Known Problem Heads:

Ford 6.0L Powerstroke:

- Insufficient head bolt clamping

- Only 4 bolts per cylinder

- TTY bolt stretch issues

- High combustion pressures

- Solution: Head studs and fire rings

Early Duramax LB7:

- Injector cup failures

- Corrosion under cups

- Coolant contamination

- Expensive repairs required

Chrysler 5.9L Common Rail:

- #6 cylinder overheating

- Poor coolant flow design

- Localized hot spots

- Aftermarket fixes available

CAT 3406E/C15 (certain years):

- Spacer plate issues

- Linear projection problems

- Head gasket failures

- Design updates helped

Manufacturing Defects:

- Porosity: Air pockets in casting

- Core shift: Internal passages misaligned

- Hard spots: Inconsistent material

- Inclusions: Foreign material in casting

- Dimensional issues: Out of spec from the factory

“Some heads are just doomed from birth,” admits an engine remanufacturer. “We see certain castings that always crack in the same place. It’s not abuse – it’s poor design or manufacturing. The aftermarket has fixes for most known issues.”

How to Identify Problem Heads:

- Research known issues for your engine

- Check technical service bulletins

- Look for updated part numbers

- Ask experienced mechanics

- Check enthusiast forums

Legal Considerations:

- Some defects are covered by extended warranties

- Class action settlements exist

- Document everything for claims

- Updated parts are often available

9. Extreme Operating Conditions

Pushing your diesel to extremes – whether for work or play – puts incredible stress on cylinder heads. While these engines are built tough, operating at the margins of their design envelope accelerates wear and increases failure risk.

High-Load Operations:

Commercial Applications:

- Heavy towing beyond ratings

- Continuous grade climbing

- Extended idle times

- Overloading consistently

- Poor maintenance schedules

Performance Applications:

- Drag racing launches

- Sled pulling events

- Dyno competition runs

- High boost pressure

- Aggressive tuning

Environmental Extremes:

High Altitude Operation:

- Reduced cooling efficiency

- Higher EGTs

- Increased boost required

- Thinner oil films

- Greater thermal stress

Temperature Extremes:

- Arctic cold starts

- Desert heat operation

- Rapid temperature changes

- Inadequate warm-up/cool-down

“We see a clear pattern,” notes a heavy equipment mechanic. “Engines in severe service fail heads at 300,000 miles. The same engine in moderate use goes 800,000. It’s not the years – it’s the abuse that counts.”

The Compound Effect:

Extreme conditions rarely exist alone:

- High load + high ambient temps = overheating

- Cold starts + immediate load = thermal shock

- High boost + poor fuel = detonation

- Extended idle + cold = bore washing

Mining/Construction Equipment:

Special challenges include:

- Continuous operation

- Dusty environments

- Shock loading

- Poor fuel quality

- Remote locations

Mitigation Strategies:

- Upgraded cooling systems

- Lower temperature thermostats

- Better monitoring systems

- Preventive maintenance increases

- Operating procedure changes

10. Age-Related Deterioration

Father Time remains undefeated, and even the best-maintained cylinder heads eventually succumb to age-related deterioration. Understanding how heads age helps you plan for eventual replacement.

How Heads Age:

Material Changes:

- Aluminum loses strength over time

- Heat cycles anneal the metal

- Grain structure coarsens

- Hardness decreases

- Fatigue resistance drops

Dimensional Changes:

- Valve seats sink

- Guides wear oval

- The deck surface erodes

- Threads weaken

- Gasket surfaces pit

The Million-Mile Question:

Even well-maintained heads show wear:

- 500,000 miles: Minor visible wear

- 750,000 miles: Measurable degradation

- 1,000,000 miles: Significant material loss

- Beyond: Living on borrowed time

Age Acceleration Factors:

- Heat cycles (not just miles)

- Operating temperatures

- Coolant maintenance history

- Oil change intervals

- Load factors

- Storage conditions

“I’ve rebuilt engines with 1.2 million miles where the heads looked like Swiss cheese,” shares a veteran rebuilder. “The owner maintained it perfectly, but metal has a lifespan. You can’t maintain your way out of material fatigue.”

When Age Mandates Replacement:

- Multiple crack repairs

- Excessive seat recession

- Guide bore wear

- Thread failures

- Previous welding repairs

- Surface pitting beyond limits

Planning for Replacement:

Smart operators plan ahead:

- Budget for eventual headwork

- Watch for early warning signs

- Don’t push aging heads hard

- Consider preventive replacement

- Keep spare heads for critical equipment

Preventing Cylinder Head Failure: Your Action Plan

Understanding why cylinder heads fail is only half the battle – preventing failure is where you save money and downtime. After 16 years of supplying replacement heads and watching failure patterns, we at FridayParts have learned that most head failures are entirely preventable.

Your Prevention Strategy:

Daily Actions:

- Check the coolant level before starting

- Watch temperature gauges religiously

- Listen for unusual noises

- Look for external leaks

- Allow proper warm-up time

Regular Maintenance:

- Change oil on schedule (not extended)

- Service the coolant system annually

- Clean the radiator and intercooler

- Replace thermostats proactively

- Adjust valves per schedule

Operating Practices:

- Avoid extended idling

- Allow a cool-down after hard runs

- Don’t lug the engine

- Fix problems immediately

- Keep detailed records

When Problems Arise:

- Don’t ignore warning signs

- Test, don’t guess

- Fix root causes

- Use quality parts

- Document everything

Remember, cylinder heads don’t usually fail suddenly – they give warnings. White smoke, coolant loss, rough idle, or power loss all signal developing problems. Catching issues early often means the difference between a 500repairanda500 repair and a 500repairanda5,000 replacement.

At FridayParts, we stock both new and remanufactured cylinder heads for all major diesel engines. But we’d rather help you prevent failure than replace heads. With proper maintenance and operating practices, your cylinder heads should last the life of the engine.

Fix it once, fix it right – and better yet, prevent the failure in the first place. Your diesel engine is counting on you to keep its head on straight.

Need cylinder heads or engine parts? FridayParts stocks thousands of new and remanufactured heads for CAT, Cummins, Detroit, Perkins, and all major diesel brands. With 16 years of experience helping customers diagnose and prevent head failures, we’re your trusted partner in diesel maintenance. Visit FridayParts.com – where quality parts meet expert knowledge.