When you enter the equipment cab, you expect the HVAC system to work properly. But what if the airflow doesn’t match your settings? In many cases, a faulty blower motor resistor may be the cause of poor air flow to the system. In this blog, we’ll detail the four most common bad blower motor resistor symptoms in heavy equipment. Let you discover and maintain in time.

Top Symptoms of a Bad Blower Motor Resistor

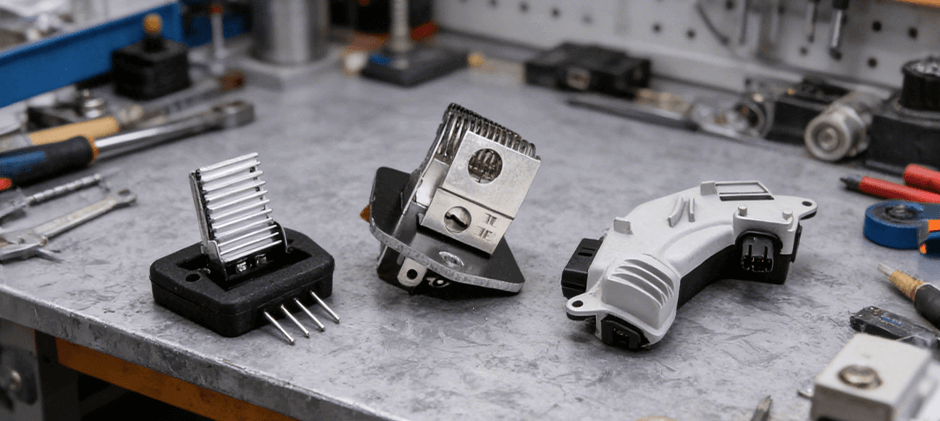

The blower motor resistor controls the fan speed. Once something is wrong, there are some very obvious symptoms.

The Fan Only Works on the Highest Setting

It didn’t respond when I turned it to low speed, and it didn’t turn in the middle gear, but it worked fine when I turned it to the highest gear. This is a typical resistor failure. Low gear passes through a resistor, and high gear is a straight-through power supply, so only high speed can rotate. In this case, the resistor is likely to fail.

Fan Speed Fluctuates

Sometimes it’s normal, sometimes some gears suddenly disappear. When working on bumpy roads, the fan will still turn and stop. This is usually a resistor or a plug with poor contact. Heavy equipment vibrates a lot, and loose wiring harnesses and terminal corrosion are common.

No Airflow from Vents on Any Speed

When the resistor is completely burned out, the fan may not work in any setting. A common cause is an internal thermal fuse blowing. But don’t rush to identify it as a resistor, it could also be:

- The fuse is blown

- The relay is broken

- The blower motor itself is broken

Not turning at all means that the circuit is broken somewhere and the resistor is just one of the possible points.

Burnt Smell or Noticeable Overheating

This is the most dangerous situation. When you turn on the fan, you smell plastic or electricity, which means the resistor is overheating. It could be a short circuit in the resistor or the blower motor pulling too much current and damaging the resistor. When checking, you might see:

- Melted resistor casing

- Blackened terminals

- Discolored or charred wires

Safety Warning: If you smell burning, turn off the HVAC right away. Don’t use it again until the problem is fixed. An overheated resistor can easily start a fire —this is extra dangerous if the machine has hydraulic fluid or fuel in it.

Causes of Blower Motor Resistor Failure

A blower motor resistor doesn’t just die for no reason. To make your new resistor last, you have to find the real cause first.

Worn-Out Blower Motor

With the motor, the bearings will wear out and the brushes will age. If the motor becomes too hard to turn, it will draw more current. Too much current will cause the resistor to overheat and be damaged prematurely.

Moisture and Corrosion

Heavy equipment works in humid and dusty environments for a long time. Once moisture enters the HVAC housing, it can cause the resistor’s terminals and coils to rust. Corrosion increases resistance and also causes higher temperatures, which ultimately leads to resistor failure.

Clogged Cabin Air Filter

Most modern machines come with a cabin air filter. A dirty filter blocks airflow. The resistor sits right in the airflow path because moving air keeps it cool. No cool air = the resistor runs too hot and burns out fast.

Normal Wear and Tear

Resistors heat up when in use and cool down when turned off — every single day. Over time, this constant heating and cooling make the metal coils brittle. Eventually, they snap right apart. It’s just part of the normal aging process.

Quick Diagnosis of Blower Motor Resistor Damage

It is not difficult to diagnose whether the blower motor resistor is damaged. Most of the steps can be done on your own as long as you prepare some basic tools.

Fan Speed Test

Turn on the ignition and turn the fan from low speed to high speed. If only the highest speed is normal and all the other speeds don’t work, there is usually a problem with the resistor.

Visual Inspection

Find the blower motor resistor, which is usually on the HVAC plenum or duct and can often be seen from behind the glove box or under the instrument panel. Unplug the electrical plug and remove the resistor. Check for obvious damage, such as:

- rust on terminals

- Scorch marks

- Plug plastic melting

These are all signs that the resistor is overheating or corroding.

Multimeter Testing

- Resistance Check: Turn the multimeter to the resistance setting (Ω). After disconnecting the resistor, measure the resistance between the terminals with a probe. There should be a specific resistance value between the mains and each speed gear. If you read “OL” or infinity, the corresponding coil is broken.

- Voltage Check (Advanced): If you are familiar with live circuit operation, you can check the voltage. Reconnect the resistor and set the multimeter to the DC voltage range. Black probe grounded. The red probe tests the voltage on each wire corresponding to the fan speed. You should see that as the fan speed increases, the voltage also increases. If it shows 0 volts where there should be voltage, there is a fault in the resistor or switch.

Pro Tip

Many people only change the resistors without checking the blower motor. If the motor current is too high, the new resistor will quickly burn out again. Be sure to check the motor at the same time to solve the underlying problem.

Repair and Prevention

After confirming that the resistor is broken, replacing it is generally simple. But prevention is also important to prevent it from breaking down again.

Replace Resistors

Just buy a new resistor. If the old plug is burned, replace it as well. Just unplug and unscrew the old one, put the new one back in place and plug it in.

Prevention

- Check or replace blower motor: It’s a good idea to check the motor before installing new resistors. If the motor is loud and turns slowly, it is most likely worn out. Aging motors can damage resistors. The motor and resistor are changed together for the most stable effect.

- Changing the cab air filter: If the filter element is too dirty, it will block the airflow and make the resistor lose heat. It is not expensive to replace the clean filter element, and it can also protect the resistor and make the air in the car cleaner.

- Use a little insulating grease: When installing a new resistor, apply a small amount of insulating grease to the terminals of the plug. This can prevent moisture and corrosion. It is especially suitable for working in dusty and humid conditions.

Summary

Now you know the symptoms of a bad blower motor resistor. If you notice any of these symptoms, check the resistor as soon as possible. You can purchase blower motor resistors and other HVAC parts on the FridayParts website and replace them if needed.