If you care about the operating efficiency of your equipment, then you will inevitably have to solve problems related to the water pumps in the equipment’s cooling system. As for this, our old customer once encountered such a question: “I am curious why the water pump is broken. The repairman often suggested that I replace the water pump when helping me replace the timing chain. Are they selling me a sales pitch? Or is there really a problem with it?” I think most equipment owners will also be confused about this question. This article explains the real causes of water pump failure, offers practical solutions, and shares how to prevent future damage. Through this article, I believe that this question will get the most authentic answer.

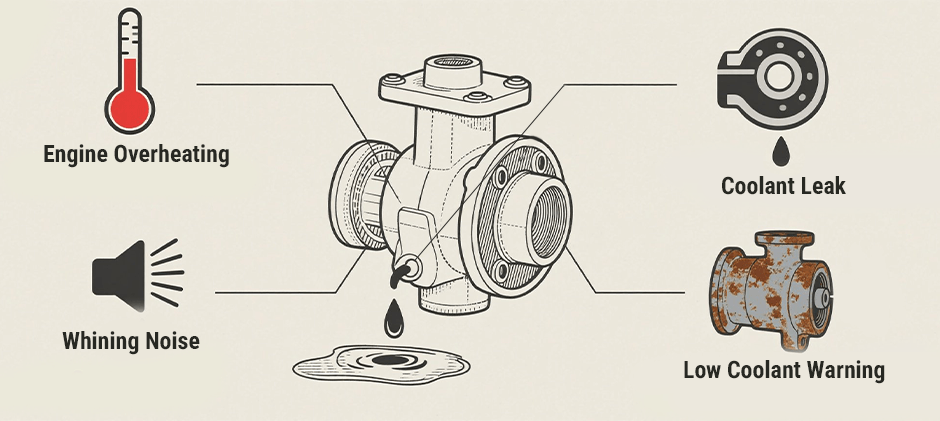

Signs Your Water Pump Is Not Working

Before identifying the exact cause of water pump failure, it’s important to recognize the warning signs. These signs help detect problems early and prevent further damage.

- Engine Overheating: If your temperature gauge stays in the red zone, the water pump may not be circulating coolant properly. Regularly check coolant levels and inspect the pump during routine maintenance.

- Coolant Leaks: Look for coolant puddles—often green or orange—under the engine. Leaks near the “weep hole” usually mean internal seal failure. Inspect the area under your machine frequently to catch leaks early.

- Whining or Grinding Noises: A high-pitched whine or low grinding sound from the engine front can indicate worn water pump bearings. Listen for unusual sounds during operation and check the pump if noise develops.

- Low Coolant Warning: If the system keeps demanding coolant even after a refill, there may be a hidden leak or pump failure. Monitor coolant levels consistently and investigate any sudden drops.

Abnormalities in the water pumps are not easy to detect. So, knowing the above signs is very important for the inspection and maintenance of the entire equipment. Learning to correctly identify these signs can avoid 90% of catastrophic engine failures.

6 Common Causes of Water Pump Failure

By now, you are almost halfway to the answer to the question at the beginning. The following direct reasons why your water pump does not work will give you a full understanding of the equipment, and you will no longer be confused about water pump damage.

1. Worn Bearings or Seals

Every water pump has internal bearings and a shaft seal. Over time, these parts wear down, especially in machines exposed to frequent vibrations or heavy-duty cycles. Once the seal breaks, coolant leaks out and can damage the bearings, leading to total failure.

2. Contaminated Coolant

Coolant isn’t just water. It contains additives that protect your system from corrosion. But if it’s old, dirty, or diluted improperly, it can carry debris or corrosive chemicals that eat away at the pump’s internals.

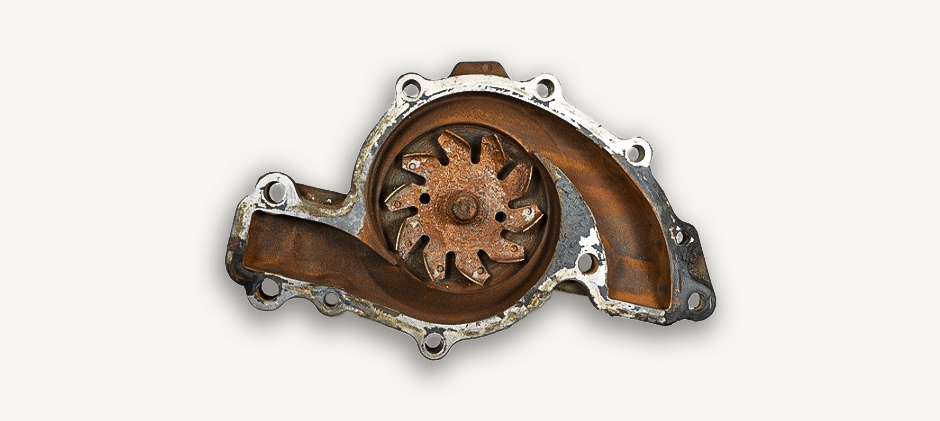

3. Corrosion

Rust and scale buildup can choke your cooling system. When coolant reacts with oxygen or incompatible metals, you get corrosion, which can damage the impeller or clog the pump entirely. ( What is Corrosion?)

4. Over-tensioned Belt

In belt-driven pumps, too much belt tension can put extra strain on the shaft bearings, leading to premature wear.

5. Air Pockets in the Cooling System

If air gets trapped in the cooling lines during servicing or after a coolant flush, it can reduce the flow rate, causing the water pump’s failure even if the pump itself isn’t broken.

6. Improper Installation or Misalignment

If a water pump is not installed correctly—such as misaligned with the drive belt system or mounted with excessive force—it can quickly lead to bearing wear, seal damage, or even impeller failure. A misaligned pump may also cause belt slippage or noise, accelerating wear and reducing cooling efficiency.

These problems might seem small at first, but they can snowball into serious damage if ignored. Knowing these common failure causes can help you spot trouble early and take action before it’s too late. Although the maintenance and inspection of water pumps are indeed necessary, do not overly neglect already very serious problems during maintenance. Water pump replacement at the right time can save more time and energy than repeated maintenance on a damaged unit.

Troubleshooting & Solutions

Knowing the signs and the reasons, I think the next question will become relatively simple. We only need to do two things to easily avoid the problems that the water pump brings to the entire cooling system. The first is to troubleshoot the problem, and the second is to replace the water pump with a new one when necessary.

Step 1: Quick Troubleshooting Checks

Before starting any inspection, safety should always come first—park the machine on level ground and make sure the engine is completely cool to avoid any risk of burns or injury. Once it’s safe to proceed, begin with a visual inspection. Look closely for any visible signs of coolant leaks around the water pumps and their connected hoses. Also, don’t forget to check the coolant level in both the reservoir and the radiator to ensure the system is properly filled.

Next, inspect the drive belt that powers the water pump. A frayed, cracked, or loose belt can compromise performance, and proper belt tension is essential for the pump to function correctly. Finally, with the engine turned off, check the pulley by grasping it firmly and gently moving it back and forth. If you notice any play or wobbling, it could be a sign of a worn bearing and likely means the water pump needs replacement.

Step 2: Water Pump Replacement

For almost all common failure causes, the only reliable solution is a complete water pump replacement. Since water pumps are sealed units, field repairs are usually ineffective and short-lived. Therefore, replacing the pump is often more cost-effective than repeated fixes. However, the purchase and selection of water pumps is often a science. Instead of spending time repairing an old one that always has the same problem, it is better to carefully select a high-quality water pump part for yourself.

Comparing prices and reviews online can help you find the best fit. In many cases, third-party suppliers offer better quality than OEMs, as they specialize in parts. Just be sure to check reviews and after-sales support to avoid unreliable sellers. If you are planning to replace your water pump but don’t know how to choose, reading the water pump selection guide will help you find the best option.

Cost to Replace Water Pump

The cost to replace a water pump on heavy equipment can vary widely, typically ranging from $1,000 to $2,800 or more. This price depends on several key factors: parts, labor, and any additional components replaced during the repair. While OEM parts are always expensive, a high-quality aftermarket option can help you save without sacrificing performance. If you’re planning a replacement, getting to know the 2025 water pump replacement cost can help you make decisions.

Conclusion

A water pump is a wear-and-tear item that will eventually need to be replaced. By recognizing the signs of failure and understanding the causes, you can address the issue before it leads to severe engine damage. When your diagnosis confirms a water pump not working, a prompt replacement is the best course of action to ensure the reliability and longevity of your heavy equipment. When a water pump replacement is necessary, we at FridayParts are your trusted partner. As a leading aftermarket parts supplier, we offer high-quality products at affordable prices. With a vast inventory and wide compatibility with many heavy equipment brands, you can find the right water pumps at FridayParts.com to get your machine back to work fast.