The A/C condenser is a critical heat exchange device responsible for cooling and liquefying the high-pressure, high-temperature refrigerant gas in the air conditioning system, preparing it for the next cooling process. Because of its exposed position and demanding job, the A/C condenser is often the first part of the system to fail. A malfunctioning A/C condenser can limit the system’s cooling efficiency, leading to poor performance. To help prevent this, FridayParts has compiled a list of core A/C condenser failure symptoms. If you experience any of these symptoms, please inspect the A/C condenser carefully and repair or replace parts as necessary.

What is the A/C Condenser Function?

Think of the A/C condenser as the radiator for your air conditioning system. Its one and only job is to get rid of heat. Inside your A/C system, a refrigerant cycles continuously. The compressor pressurizes this refrigerant, turning it into a very hot, high-pressure gas. This hot gas then flows into the A/C condenser. As air passes over the condenser’s fins, it pulls the heat out of the refrigerant, causing it to cool down and condense from a gas back into a high-pressure liquid. This cooled liquid then continues its journey to the evaporator coil inside your cab, where it expands and becomes ice-cold, giving you the cool air you depend on.

On most heavy equipment like excavators, dozers, and loaders, the A/C condenser sits in the main cooling pack, usually right in front of the radiator and hydraulic oil cooler. This spot gives it maximum airflow from the engine fan, but also makes it highly exposed to job site damage.

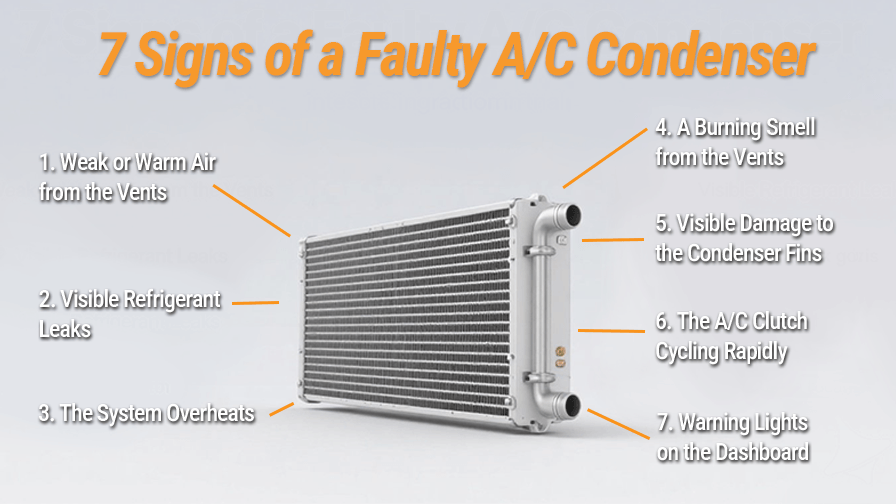

7 Signs of a Faulty A/C Condenser

A failing A/C condenser will almost always give you warning signs. Please pay close attention to the operating status of your equipment. If the following symptoms occur, please consider repairing the A/C condenser in time.

1. Weak or Warm Air from the Vents

This is the most obvious and common symptom. This happens for two main reasons related to the condenser:

- External Blockage: The condenser’s fins are clogged with dirt, mud, grass, or other debris. If air cannot pass through the fins, it cannot remove heat from the refrigerant. The refrigerant stays hot, and the system cannot produce cold air.

- Internal Blockage: Debris or contaminants inside the A/C system can create a clog within the small tubes of the condenser. This restricts refrigerant flow, crippling the system’s cooling ability.

2. Visible Refrigerant Leaks

The A/C condenser holds refrigerant under very high pressure. Over time, vibration, impacts, or corrosion can cause small cracks or failed seals, leading to leaks. Because the refrigerant contains oil to lubricate the compressor, a leak will often present as:

- A Greasy, Oily Residue: You’ll notice an oily film on the condenser fins or their connections.

- Dust and Dirt Accumulation: On a dusty job site, this oily residue will quickly attract and hold onto dirt, creating a grimy patch that is a telltale sign of a leak.

3. The System Overheats

Your machine’s A/C system is designed to handle a massive heat load. If the condenser is failing, it can’t get rid of that heat effectively. This problem is most noticeable when the machine is idling. While moving, there is some natural airflow, but at idle, the system relies entirely on the engine fan.

“A faulty condenser can cause system pressures to skyrocket, especially at low engine RPMs. The system’s high-pressure switch will often shut the compressor off to protect it, which is why your A/C might seem to work intermittently or cut out completely when you’re not actively working,” said senior maintenance master Peter.

4. A Burning Smell from the Vents

A burning smell when you turn on the A/C is a serious red flag. While a musty smell might just indicate mold in the evaporator, a sharp, acrid burning smell points to a component overheating. When the A/C condenser is clogged or failing, it puts immense strain on other parts, especially the A/C compressor. This strain can cause the compressor’s clutch or internal parts to overheat, creating a distinct burning odor that travels through the vents.

5. Visible Damage to the Condenser Fins

Take a moment to visually inspect your condenser. On off-road equipment, it takes a constant beating. Look for:

- Bent or Flattened Fins: Rocks, branches, or high-pressure washing can easily bend the delicate aluminum fins. Large patches of bent fins will severely restrict airflow.

- Corrosion: In wet or corrosive environments, the condenser can degrade over time, leading to weak spots and leaks.

6. The A/C Compressor Clutch Cycles On and Off Rapidly

Listen to your A/C compressor. It’s normal for the clutch to cycle on and off periodically. However, if you hear it clicking on and off every few seconds, this is called “short cycling.” It’s often a symptom of incorrect system pressures, which can be directly caused by a blocked or inefficient A/C condenser. The system builds pressure too quickly, hits the high-pressure limit, shuts off, and then repeats the process over and over.

7. Warning Lights on the Dashboard

Many modern machines are equipped with sophisticated monitoring systems. While there may not be a specific light for the “A/C Condenser,” a fault in the A/C system can sometimes trigger a general engine or system warning light. If a warning light appears at the same time you notice poor A/C performance, it’s a clear signal to run a diagnostic check.

What Happens if the A/C Condenser Fails?

Ignoring a failing A/C condenser will lead to a cascade of expensive problems. A simple condenser issue can quickly destroy your entire A/C system.

- Compressor Destruction: A clogged condenser causes extremely high pressure and heat, forcing the compressor to work much harder until it burns out. It can also cause liquid refrigerant to back up into the compressor, which is designed to compress gas only. This “slugging” will shatter the compressor’s internal parts.

- System-Wide Contamination: When a compressor fails, it sends metal shavings and debris throughout the entire A/C system. This contaminates every single component—the hoses, the evaporator, the expansion valve—turning a single part replacement into a full system flush and replacement, a much more costly and labor-intensive job.

How Long Should the A/C Condensers Last?

While an A/C condenser on a passenger car might last 10-15 years, the lifespan on heavy equipment is entirely different and far more variable. Heavy equipment air conditioning condensers can last 6-10 years with proper maintenance. If rigorous regular maintenance is performed, they can even last up to 15 years.

Repairing vs. Replacing

Sometimes the A/C condenser does not need to be completely replaced and only needs minor repairs to restore normal operation, but sometimes replacement is unavoidable. Here’s how to decide:

Issues That Can Often Be Repaired:

- Dirty/Clogged Fins: Thorough cleaning with a low-pressure washer and a fin comb to straighten minor bends can often restore performance.

- Minor Leaks at Fittings: Sometimes, simply replacing an O-ring or re-torquing a fitting can solve a small leak.

- Faulty Fan Motor/Relay: If the condenser itself is fine but its dedicated electric fan (if equipped) has failed, you can replace just the fan assembly.

Problems That Require Condenser Replacement:

- Major Internal Blockage: If the system is contaminated, the condenser must be replaced. It’s impossible to flush all the debris out of its tiny passages.

- Widespread Leaks: If the condenser has multiple leaks or corrosion points in the core, replacement is the only reliable solution.

- Heavy Physical Damage: If a large area of the condenser is crushed or damaged beyond what a fin comb can fix, its efficiency is permanently compromised, and it must be replaced.

If your A/C condenser needs extensive repair but your budget is limited, we highly recommend choosing aftermarket A/C condensers from FridayParts. While third-party replacements offer comparable quality at lower prices than original equipment manufacturers, they can also offer comparable performance. Furthermore, with a little screening, you can save significant repair costs.

Summarize

Your machine’s A/C condenser is a hardworking component in a tough environment. Knowing these seven key signs of failure allows you to act quickly, protecting the rest of your A/C system from a chain reaction of damage. Regular visual inspections and cleaning are the best preventative measures you can take.

When a replacement is necessary, you need a part that is both durable and affordable to minimize downtime. At FridayParts, we specialize in high-quality aftermarket parts for a wide range of heavy equipment brands. Our vast inventory ensures you can find the right A/C condenser at a great price, getting your cab cool and your operation back to peak productivity without delay.