Even though you might not know the brand, I bet you have seen its scissor lifts working on the street—JLG. JLF is a leading name in the access industry, known for its AWP(Ariel Working Platform). If you’re a JLF owner or operator, you must know that keeping this machinery in top working condition is a crucial step for keeping safety and productivity. Do you know how to select the best components or replacements for your equipment? Replacing worn or damaged parts is a significant part of JLG equipment repair or update, and special tools are required. While many tasks can be handled with a standard mechanic’s toolkit, certain jobs demand JLG special tools or specialized equipment to ensure the JLG parts are installed correctly and safely.

In this guide, I will walk you through the types of tools you might need for JLG equipment repair, from basic essentials to more specialized items. Understanding what tools for JLG maintenance are required will help you tackle repairs efficiently.

Also read: How Can I Find the Right JLG Parts for My Machine?

Why Do You Need a Special Tool for JLG Parts Installation?

Using the correct tools when you install JLG components isn’t just about making the job easier. Here are some considerations:

- Safety: Incorrect tools can lead to accidents, damaging the part, the machine, or even causing injury. Specialized tools are often designed to handle the specific forces and angles required for JLG machinery.

- Preventing Damage: JLG equipment contains precise and sometimes delicate systems. Using a generic tool where a specialized one is needed can strip threads, crack housings, or misalign components, leading to costly further repairs.

- Ensuring Proper Fit and Function: Many JLG parts, especially sensors and hydraulic components, require precise installation and calibration. JLG special tools help achieve the manufacturer’s specifications, ensuring the new part functions as intended.

- Efficiency: Having the right tool for the job saves time and frustration. What might be a lengthy struggle with an ill-suited tool can often be a quick and straightforward process with the correct one.

General vs. Specialized Tools for JLG Equipment

For many routine maintenance tasks and simpler JLF parts installation jobs, a comprehensive set of standard machic’s tools will suffice. These include:

- Wrench Sets: Combination, socket, and Allen wrenches in various sizes (metric and imperial).

- Screwdrivers: Phillips, flathead, and Torx drivers.

- Pliers: Needle-nose, slip-joint, and wire cutters/strippers.

- Hammers: Ball-peen and dead-blow hammers.

- Measuring Tools: Tape measure, calipers.

However, when you delve into more complex repairs or specific component replacements, the need for JLG maintenance tools or even JLG special tools becomes apparent. These are tools designed for particular tasks on JLG machinery, ensuring precision and safety.

Key Categories of Tools for JLG Repair and Installation

Now, let’s break down the types of tools you might encounter when working with JLG lifts.

Basic Hand Tools: As mentioned, these are your everyday essentials. Always opt for high-quality, durable tools.

Diagnostic Tools

Modern JLG lifts incorporate sophisticated electrical and hydraulic systems, so you will need diagnostic tools.

- Multimeter: Essential for any electrical troubleshooting, like checking fuses or sensor circuits.

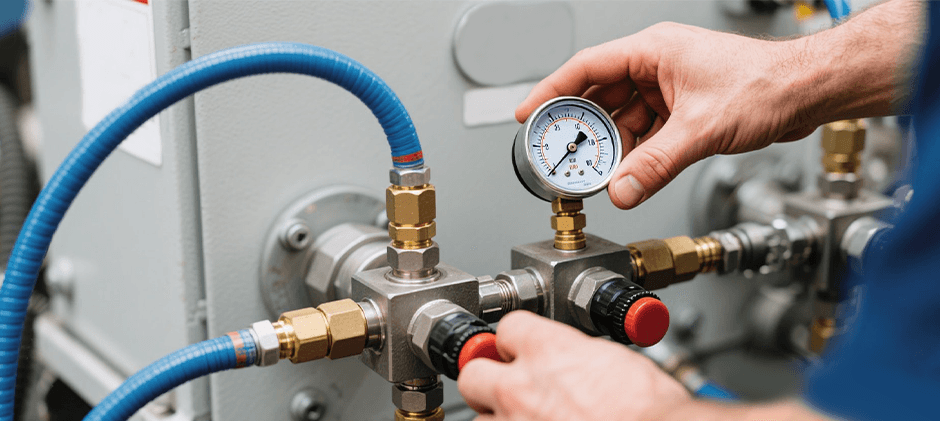

- Hydraulic Test Kit: Crucial for diagnosing issues within the hydraulic system. This kit typically includes pressure gauges, hoses, and fittings to measure hydraulic pressures at various points. These are vital JLG hydraulic system tools.

- Diagnostic Tools for JLG Lifts: JLG offers its own diagnostic software and hardware (like the JLG Analyzer) that interfaces with the machine’s control system to read error codes, monitor live data, and perform calibrations.

Lifting and Support Equipment

- Heavy-duty Jacks and Stands: Essential for safely lifting and supporting the machine or its components during repair.

- Hoists or Cranes: For removing or installing heavier JLG parts like engines, axles, or boom sections.

Specialized JLG Tools and Kits

This is where the tools needed for JLG repair become very specific.

- Fuse Replacement Tool: While some fuses are standard, specific JLG designs might benefit from a dedicated tool for safe removal and insertion in tight spots.

- Axle Repair Tools: Working on axles, bearings, or seals often requires specialized pullers, drivers, or alignment jigs.

- Huck Bolt Tool: JLG uses Huck bolts in some structural applications. These require a specific Huck bolt tool for proper installation and removal, ensuring the correct clamping force.

- ZF Driver Tool: If your JLG equipment uses ZF axles or transmissions, specific driver tools might be needed for servicing these components.

- Tilt Sensor Calibration Tools: Proper calibration of tilt sensors is critical for the safe operation of boom and scissor lifts. This often requires specific jigs or electronic tools.

- Load Sensor Installation and Calibration Tools: Similar to tilt sensors, load sensors are vital safety features. Their installation and calibration demand precision, often necessitating JLG lift sensor tools or boom lift calibration tools.

- Tools for Platform Gate Installation: Ensuring the operator platform gate is correctly installed and functioning is a key safety check. This might involve specific alignment tools or fasteners.

- JLG Service Kit Components: Some JLG service kit options may include specialized tools alongside the replacement parts for a particular job.

- Crimp Tool: For electrical repairs, a quality crimp tool designed for the specific type of connectors used in JLG wiring harnesses is essential for reliable connections.

- Operator Platform Tools: Specific tools might be needed for repairing or replacing components on the operator platform itself.

Examples of JLG Parts Installation and Required Tools

Listing the tools is sometimes abstract, but with some specific examples, you may gain a deeper understanding of the repair job. The thing, how too install JLG parts often starts with consulting the service manual. This document is invaluable as it typically lists any JLG special tools required for a procedure.

- Replacing a Hydraulic Cylinder Seal: This would require standard wrenches and sockets, a seal puller, a seal installation tool (sometimes specific to the cylinder diameter to prevent damage to the new seal), and a hydraulic test kit to verify pressures post-repair.

- Installing a New Controller: Besides basic hand tools for removal and mounting, you would likely need diagnostic tools for JLG lifts to program or configure the new controller to the specific machine.

- Boom Lift Maintenance Tools vs. Scissor Lift Repair Tools: While there’s a lot of overlap, some tools might be more specific. For example, complex boom sections might require specialized alignment jigs not typically needed for simpler scissor lift structures. However, both will require tools for hydraulic and electrical systems. Specific tools for JLG scissor lifts might include those for tight access areas, common in their compact design.

Conclusion

Successfully performing JLG parts installation and maintenance hinges significantly on using the correct tools for JLG repair. While a standard toolkit covers many bases, investing in or having access to JLG special tools and diagnostic equipment is often necessary for more complex tasks, ensuring safety, efficiency, and the longevity of your valuable JLG equipment. Always prioritize quality tools and consult your service manual.

If you’re looking for high-quality aftermarket JLG parts to go with your well-equipped toolbox, we at Fridayparts can help. We pride ourselves on offering a vast inventory of reliable components for a wide range of heavy equipment brands, including JLG, all at affordable prices. Our goal is to get you the right JLG parts quickly, so you can get your machinery back to work. Explore our selection today and ensure your JLG equipment operates at its best!