If you’re planning an off-road, construction, or excavation project, choosing the right Bobcat excavator size can make or break your job’s success. However, with numerous Bobcat models—ranging from their smallest compact units like the E10 to their largest E165—it’s not always clear which machine best meets your project’s needs. In this complete guide, we’ll break down Bobcat excavator sizes, specifications, and selection criteria to help you find the perfect balance between power, reach, and maneuverability.

What Are Excavator Size Classes?

Excavators are broadly categorized by their operating weight, which affects their digging power, reach, and transportability. Bobcat divides its excavators into two major classes — Compact (Mini) and Large (Standard).

Here’s a simple breakdown:

- Compact Excavators (Mini, under 10 tons):

Ideal for tight spaces, landscaping, and urban construction work. They’re lightweight, easier to transport, and perfect for precision tasks.

- Large Excavators (10–45 tons):

Built for massive earthmoving, deep trenching, and demolition projects. These heavy-duty machines are designed for power, depth, and stability.

For most off-road machinery owners, understanding size classification is the first step. A miscalculated size not only wastes fuel and time but could also damage your site or machine by overstraining hydraulic and structural systems.

Bobcat Excavator Sizes Chart & Specifications

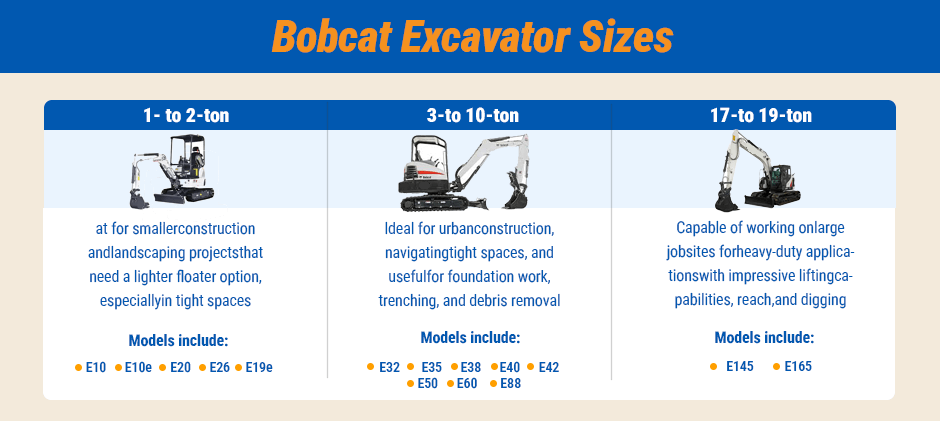

Bobcat excavators are grouped into three tonnage classes — mini (under 6 tons), mid-size (6–10 tons), and large (over 10 tons) — each designed to handle specific project demands. These classes help operators choose models suited precisely to their off-road, landscaping, or construction needs. Below, we summarize the main categories and specifications to help you choose correctly.

1. Mini Excavators (1–6 Tons)

Best for: Compact work areas, landscaping, small construction sites, and residential excavation.

Mini excavators are lightweight, maneuverable machines perfect for confined areas where space, noise, or ground disturbance are concerns. Bobcat’s mini lineup (E10–E35) is popular among contractors for quick transport and low operating costs.

| Model | Operating Weight (lbs) | Tonnage Class | Dig Depth (ft) | Max Reach (ft) | Engine Power (HP) |

|---|---|---|---|---|---|

| E10 / E10e | ~2,600 | 1.2–1.3 ton | 6–7 | 10–11 | 10–11 |

| E19 / E20 | 4,000–4,300 | 2 ton | 8–9 | 13–14 | 15 |

| E26 / E27 | 5,800–6,200 | 2.5–3 ton | 9–10 | 15–16 | 24 |

| E32 / E35 | 7,000–7,660 | 3–3.5 ton | 10–12 | 17–18 | 25–33 |

Highlights:

- Ultra-compact tail-swing designs for narrow access points

- Lower fuel use

- Ideal for trenching, backfilling, and utility line work

- Simple transport — most fit on a single-axle trailer

- Electric variants (like the E10e) are available for emission-free worksites

2. Mid-Size Excavators (6–10 Tons)

Best for: Site preparation, road work, moderate foundation digging, or off-road utility repair.

Mid-size Bobcat excavators cover the middle ground between agility and muscle. Machines like the E50, E55, and E60 deliver more digging depth and breakout force while keeping mobility intact. These are versatile “all-rounders” suitable for general contracting and construction firms that tackle varied terrains.

| Model | Operating Weight (lbs) | Tonnage Class | Dig Depth (ft) | Max Reach (ft) | Engine Power (HP) |

|---|---|---|---|---|---|

| E42 / E48 | 9,800–10,200 | 5 ton | 12 | 18–19 | 42–48 |

| E50 / E55 | 11,300–12,300 | 5.5–6 ton | 13–15 | 20–21 | 50 |

| E60 / E63 | 12,400–13,800 | 6–6.5 ton | 14–15 | 21 | 55 |

| E85 / E88 | 18,900–19,600 | 8.5–9.5 ton | 15–16 | 23 | 65 |

Highlights:

- An extended dig depth is ideal for trenching and foundation preparation

- Optional long-arm configurations for extended reach

Heavier undercarriage improves balance and breakout stability - R2-Series enhancements: touch display, hydraulic X-Change, and depth-check systems

Mid-tier units like the Bobcat E55 or E60 are favorites among road and drainage contractors because they bridge power and portability — they can dig, lift, and backfill without exceeding hauling limits.

3. Large Excavators (Over 10 Tons)

Best for: Earthmoving, quarry operation, pipeline trenching, and large-scale infrastructure projects.

Large Bobcat excavators such as the E145 and E165 are engineered for tough, continuous workloads. They bring high power-to-weight ratios, long arms, and reinforced frames fit for demanding sites. These models compete with full-size crawler excavators used in commercial and mining operations.

Highlights:

- Four engine modes (Power+, Power, Standard, Economy)

- Superior hydraulic flow for heavy attachments

- Ideal for rock removal, major drainage, or demolition operations

- Enhanced cabin insulation for noise reduction and comfort over long working hours

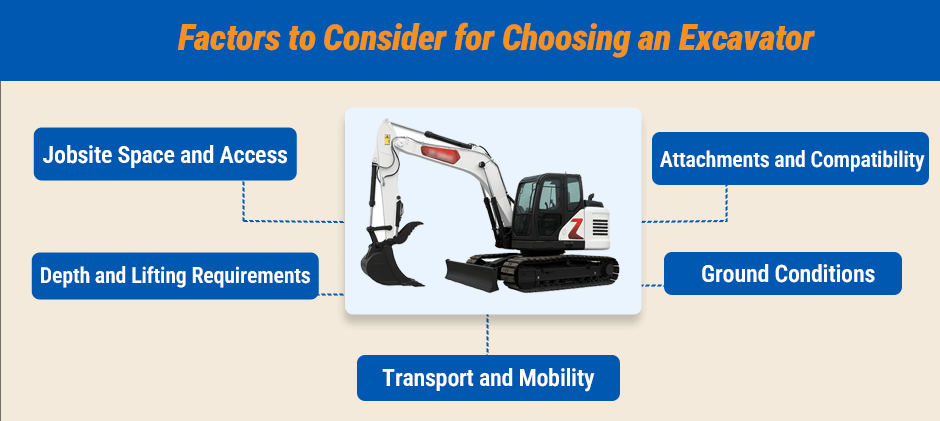

Factors to Consider When Choosing an Excavator

Before you commit to a size, consider your operating conditions and task requirements. Excavators aren’t just judged by their specs; how they perform in real-world conditions matters most.

1. Jobsite Space and Access

- Tight urban or forest areas: Go compact (under 10 tons).

- Open-field or quarry terrain: You’ll benefit from large excavators for deeper and faster digging.

Lightweight, small machines like the Bobcat E20 or E26 fit through gates and between structures easily—large units like the E145 are often impossible to maneuver in restricted zones.

2. Depth and Lifting Requirements

- Digging shallow trenches for irrigation lines? Mini units like the E19 work best.

- Excavating deep foundations or heavy rock layers? The E88 to E165 range delivers sufficient reach and torque.

3. Transport and Mobility

Heavier units require specialized trailers and travel permits. Compact excavators, on the other hand, fit on standard haulers—ideal for contractors moving between multiple off-road projects daily.

4. Attachments and Compatibility

Bobcat’s versatility lies in its attachment options—buckets, hammers, augers, and grapples. Ensure your chosen model provides compatible hydraulic flow rates. You can maintain performance by investing in quality excavator parts and accessories optimized for Bobcat equipment.

5. Ground Conditions

Soft soil or turf? Choose lighter excavators with rubber tracks. Rugged or rocky terrain? Opt for heavy-duty steel-tracked models to prevent undercarriage wear.

How to Choose the Best Excavator Size?

Selecting the right Bobcat excavator size isn’t simply comparing horsepower—it’s evaluating fit for purpose, efficiency, and comfort. Let’s explore the logic step-by-step.

Step 1: Define Work Type and Environment

Ask yourself:

- Are you grading slopes, demolishing, or trenching?

- Is your work area urban, agricultural, or off-road?

- Will you need to transport the machine daily?

For instance, a contractor doing trench utility installations might prefer a compact E35, while a forestry operator handling rocky soil might invest in an E145 for more torque and track pressure.

Step 2: Match Dig Depth and Reach to Job Requirements

Here’s a simple guide:

| Job Type | Recommended Bobcat Size Range | Example Models |

|---|---|---|

| Landscaping / Residential | Mini (1–3 tons) | E10, E19, E20 |

| Construction Foundations | Mid (4–8 tons) | E32, E35, E42 |

| Utility Work (Sewer, Irrigation) | Mid–Large (6–12 tons) | E50, E55, E60 |

| Heavy-Duty Projects / Earthmoving | Large (17+ tons) | E88, E145, E165 |

The right balance of reach and stability guarantees efficiency. Oversizing adds unnecessary fuel costs; undersizing strains hydraulics and reduces productivity.

Step 3: Evaluate Operating Costs and Maintenance

While bigger models offer better performance, they demand more fuel and frequent service intervals. If your projects vary, a medium model like the E50 or E60 offers a sweet spot between cost and versatility.

Regular maintenance is key — and that means investing in dependable component replacements. Check out FridayParts’ selection of Bobcat parts to keep your excavator running longer without OEM markup costs.

Step 4: Consider Attachments and Future Jobs

Bobcat excavators support modular attachments. Choose a machine that supports upgrades — like advanced hydraulic kits or adjustable booms — to expand its value across diverse projects. When eventually upgrading or reconfiguring your equipment, getting aftermarket part compatibility through trusted suppliers ensures seamless adaptation.

Compact vs. Large Excavators: Which Is Right for You?

| Factor | Compact (Mini) | Large |

|---|---|---|

| Work Surface | Tight or irregular spaces | Large, open fields |

| Applications | Light digging, landscaping | Deep trenching, demolition |

| Transportability | Easy | Heavy-duty hauling required |

| Operating Cost | Low fuel and maintenance | High fuel consumption |

| Power Output | Moderate | High torque and breakout force |

Compact excavators excel in municipal or off-road maintenance. Large excavators dominate in heavy earthmoving operations such as pipeline installation, road base excavation, or industrial-grade grading.

For mixed operations, a 5–6 ton machine like the E50 delivers optimal flexibility — that’s why it’s among the bestselling choices for contractors balancing power and mobility.

Additional Tips for First-Time Buyers

- Review warranty and service intervals. A reliable supplier provides post-purchase service support.

- Prioritize hydraulic flow specs. These determine how efficiently your attachments run.

- Look for operator comfort upgrades. Features like low-effort joysticks and touchscreen diagnostics boost productivity.

- Stock essential parts early. Having backup filters, seals, and starter components prevents job interruptions.

FridayParts offers OEM-quality excavator parts and specialized Bobcat parts for your maintenance needs—affordable, reliable, and with worldwide shipping.

Conclusion

Choosing the ideal Bobcat excavator size doesn’t have to be confusing. Evaluate your site, define your excavation objectives, and balance power with control. Whether you select a lightweight E19 or a powerful E145, the right match boosts productivity and minimizes cost across your off-road operations. To maintain that performance, source durable replacement parts from FridayParts, your trusted aftermarket provider for high-quality Bobcat parts and compatible excavator parts — keeping your fleet efficient, affordable, and always job-ready.