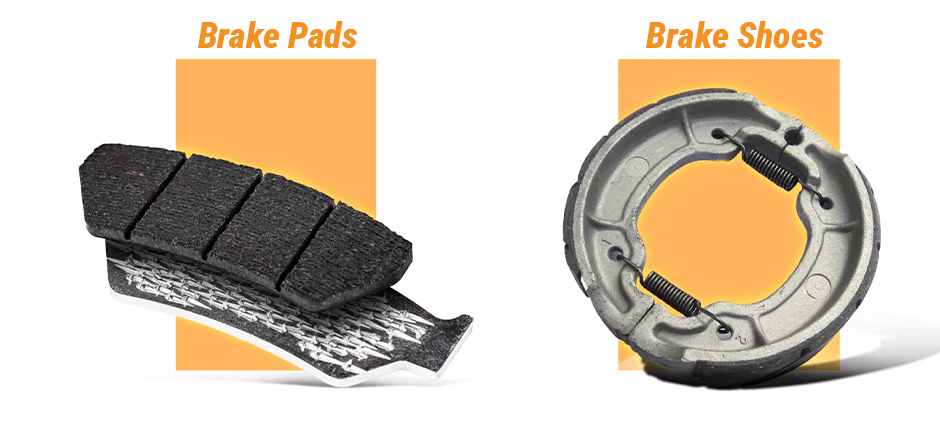

Brake pads and brake shoes are not the same thing. They often are confused, especially when your machine is simultaneously equipped with both of these components. Although they both are utilizing friction to reduce the speed of the machine, they are not interchangeable, and they operate in completely different systems. This article will explain the difference between the two, helping you to clearly identify brake pads and brake shoes, and to avoid making mistakes when repairing or purchasing parts.

What are Brake Shoes and Brake Pads?

Before making the comparison between these two components, it is necessary for us first to understand their respective meaning and also their role within the specific braking system.

What is a Brake Shoe?

The brake shoe belongs to the primary friction component within the drum-type braking system. It is the crescent-shaped metallic piece, on one side of which is adhered or riveted a thick and heat-resistant friction lining.

- Key Characteristic: One main characteristic of the brake shoe is its so-called “self-energizing” or “servo” effect. The rotation of the brake drum is in fact being able to assists the brake shoes to be wedged more tightly into the brake drum, thus increasing the braking force without the necessity of extra pressing of the pedal. This is making them become a very effective parking brake.

What is a Brake Pad?

The brake pad belongs to the frictional component, which is used inside the disc-type braking system. It consists of one piece of the flat and heavy-duty steel back plate, and one piece of the frictional material that is adhered to the surface of it.

- Key Characteristic: The main advantage of the brake pad and brake disc system is existing inside its excellent capacity of heat dissipation. The flat surface of the exposed rotor allows the air to pass through, thus achieving quick cooling and reducing the risk of the brake performance declining during the frequent and repeated utilization process.

Brake Shoes vs Brake Pads: What Are the Differences?

Although both of these kinds of systems are intended for stopping your machine, their method, performance characteristics, and maintenance requirements are being greatly different. To understand these kinds of distinctions is of vital importance for any equipment owner or mechanic.

1. Direction of Force and Mechanism

The key difference lies in how they apply force.

Brake Pad: Pressing inward. The caliper gives direct, even pressure to both sides of the rotor, making braking linear and predictable.

Brake Shoe: Pushing outward. The wheel cylinder drives shoes away from center. With drum rotation, a self-energizing effect appears, where one shoe wedges into the drum, increasing force.

2. Stopping Power and Heat Dissipation

For heavy equipment, heat control is crucial. Overheating causes brake fade, friction weakens, and force drops.

Brake Pad: Disc brakes manage heat better. Exposed rotors act like radiators, releasing heat into air, allowing repeated strong braking, useful on slopes or fast cycles.

Brake Shoe: Drum brakes dissipate heat poorly. Enclosed drums trap heat, expand, and move away from shoes, thus reducing braking force.

3. Durability and Service Life under Off-Road Conditions

This is a more nuanced comparison.

Brake Pads: Exposure has pros and cons. Pads and rotors face dust, mud, and water, but rotor rotation throws off debris, and pads wipe the rotor, self-cleaning.

Brake Shoes: Drum brakes’ enclosed design protects well, giving longer life in dusty or muddy conditions. However, trapped grit or water can quickly wear shoes, scratch drums, and reduce braking.

4. Maintenance and Servicing Convenience

This is a key consideration for minimizing downtime.

Brake Pads: Replacement is simpler and faster. Technicians can quickly remove the caliper, retract the piston, replace pads, and reassemble.

Brake Shoes: Drum brake repair is more complex and time-consuming. Disassembly of the drum and careful handling of springs, clips, and adjusters is required, increasing labor cost.

Here is a detailed breakdown of the critical differences:

| Feature | Brake Pads (Disc Brakes) | Brake Shoes (Drum Brakes) |

|---|---|---|

| Mechanism | Squeeze inward on a rotor. | Push outward against a drum. |

| Stopping Power | Generally higher and more consistent. | Good, with a self-energizing effect. |

| Heat Dissipation | Excellent; exposed rotor cools quickly. | Poor; enclosed drum traps heat |

| Performance in Wet | Excellent; water is flung off the rotor. | Poor; water can get trapped inside. |

| Maintenance | Simpler, faster to replace pads. | More complex, with many small parts. |

| Durability | Exposed to elements, but self-cleaning. | Protected from elements, but traps debris. |

| Primary Use | High-speed applications, front axles. | Rear axles, parking brakes, slower machines. |

How Do You Know if Your Machine Uses Brake Pads or Brake Shoes?

It can be judged through the observation of the brake of your equipment. If it is appearing like the left picture, and you are able to see one shining round disc, then your equipment is using the brake pad. If what you are seeing is the drum-type brake like the right, then your equipment is using the brake shoe.

The Different Types of Brakes on a Vehicle

To fully grasp the roles of pads and shoes, we must first understand the two primary types of braking systems found on off-road machinery where these components live.

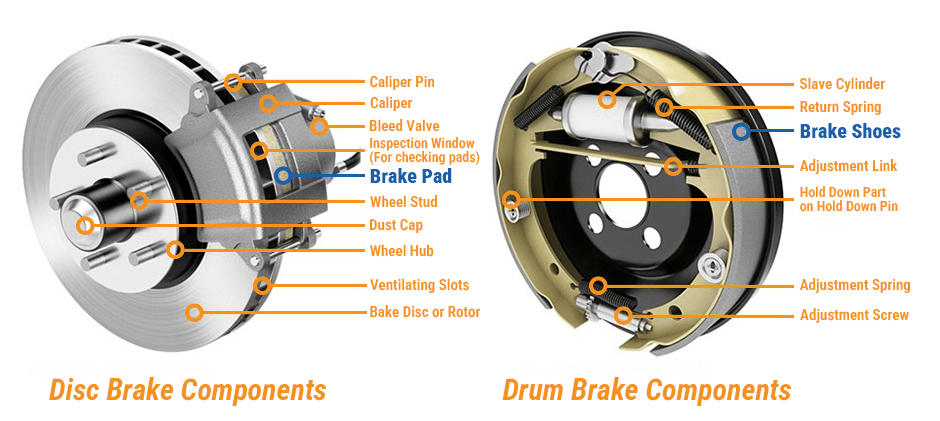

Disc Brake

The disc brake system belongs to the modern standard for the majority of high-performance and heavy-duty applications, especially located on the front axle of wheeled equipment.

- Appearance: If you are making the observation at the rear side of the steering wheel of the vehicle, which is equipped with the disc brake, you will see one huge, shining, and flat metallic rotor. At the same time, you will also notice one bulky caliper component embracing a certain portion of the rotor.

- Components: This system consists of the rotor, the caliper, and the brake pads.

- Function: As described in the above manner, the caliper is pressing the brake pads onto the rotor. This design is providing superior braking force, and the most important point is that it possesses outstanding management of heat management. Many of the heavy-duty rotors are also carrying the ventilation structures, which means that they have the internal channels that can, in a manner like a fan, inhale the cold air, furthermore enhancing their capacity to resist the overheating.

Drum Brake

The drum brake belongs to one of the more old, but still in the wide used designs, usually being installed on the rear axle of the equipment, or being used as a special parking brake system.

- Appearance: The drum brake system is looking like one large and solid cylindrical brake drum, inside which it is wrapping all the brake components. From the outside, it is not possible to see the brake shoes.

- Components: This system is composed of the brake drum, the brake shoes, the wheel cylinder, and also a series of complicated springs and regulators, these springs and regulators are making all the components fixed in position.

- Function: The brake shoes are pressing outward towards the inner side of the brake drum. Because this system is the closed type, therefore it can effectively prevent the pollution of mud, dust, and water, which in the harsh off-road environment has a significant advantage.

How do you know if your machine uses brake pads or brake shoes? It can be judged through the observation of the brake of your equipment. If it is appearing like the left picture, and you are able to see one shining round disc, then your equipment is using the brake pad. If what you are seeing is the drum-type brake like the right, then your equipment is using the brake shoe.

Do I Need Brake Pads or Brake Shoes?

This question is very easy to answer: your machine requires the specific component that was equipped during its design.

You cannot use brake pads in a drum brake system, nor can you use brake shoes in a disc brake system. Many heavy-duty machines simultaneously use both types of brakes—usually, disc brakes are installed on the front axle to bear most of the braking force, while drum brakes are installed on the rear axle.

Before ordering brake components, the critical task is to correctly identify the system installed on each axle of the machine. Visual inspection is the best method: if you see a large, flat, shiny disc and a caliper, you need brake pads. If you see a large, enclosed metal drum, you need brake shoes.

Troubleshooting Brake Pads vs Brake Shoes

The symptoms of the problem can usually help you to locate the correct system.

- Loud Squealing or Grinding: This is a common sign of wear of the friction material. Most brake pads are equipped with a small metal piece called the wear indicator, which will emit a sharp squeal when the pad has little wear remaining. If you hear harsh friction noise, it indicates the friction material is completely worn out, and metal-to-metal contact occurs, which can severely damage your brake disc or brake drum. When you hear such noises, you should immediately inspect the symptoms of brake pad damage or the brake shoes.

- Machine Pulls to One Side When Braking: This usually indicates there is a problem with the brake of a specific wheel. In a disc system, it may be that the caliper piston is stuck. In a drum system, it may be the wheel cylinder leaking, causing brake fluid to contaminate the brake shoe.

- Spongy or Soft Brake Pedal: This typical symptom usually shows that there is air in the hydraulic lines, which affects both systems equally. It may also indicate a leakage. Now is a good time to consider how often to change brake fluid, so the pedal remains firm and internal corrosion is prevented.

- Vibration or Pulsating in the Pedal: This is almost always a disc brake issue, caused by warped brake rotors.

Final Summary

The main difference between brake shoes and brake pads is primarily regarding the direction of force applied, heat control, durability and lifespan, as well as the difficulty of maintenance. Understanding the fundamental distinction between the two is crucial for the safe and efficient operation of heavy-duty equipment. This can enable you to find the correct parts when maintaining the equipment. When needing to repair the brakes, selecting high-quality aftermarket brake shoes or brake pads from a well-stocked supplier such as FridayParts can ensure you obtain reliable braking power, perfect compatibility, and excellent cost-performance, thereby minimizing downtime and ensuring the safety of your operation.