Filters are the lungs of heavy machinery. Whether it’s a breather filter or an air filter, these components play a critical role in keeping your equipment running smoothly. But here’s the kicker—many operators don’t actually know the difference.

If you’ve ever wondered why your engine struggles to perform or why hydraulic systems overheat, the culprit could be as simple as using the wrong filter—or failing to replace one in time. Understanding the breather filters vs air filters debate is crucial for equipment maintenance, engine longevity, and overall performance. So, let’s break it down.

What Is a Breather Filter?

A breather filter is like a lung for your machinery—it lets air flow in and out while blocking contaminants. But why does this matter?

Purpose of a Breather Filter

Breather filters prevent pressure buildup inside sealed systems like hydraulic tanks, crankcases, and fuel reservoirs. These systems naturally expand and contract due to temperature changes, and without a breather, you’d get vacuum pressure, which can lead to fluid contamination, leaks, or even system failure.

What Happens If the Breather Is Blocked?

Think of it like trying to breathe through a clogged straw—your system struggles, and pressure builds up. A blocked breather filter can cause:

- Oil leaks due to pressure imbalance.

- Premature seal failure, leading to costly repairs.

- Contaminant buildup, increasing wear and tear.

To avoid the aforementioned tragedies, you need to clean or replace the part regularly. The recommended replacement time for a breather filter in heavy equipment typically ranges from 500 to 1,000 hours of operation, but factors like dusty environments, frequent use, or severe weather conditions can shorten the breather filter’s lifespan. So remember to check the aging degree of your breather filter and replace it in time.

Common Equipment That Uses Breather Filters

- Excavators – Hydraulic systems rely on breathers to keep fluid clean.

- Tractors – Crankcase breathers prevent oil mist and debris from damaging the engine.

- Heavy-duty trucks – Transmission breathers regulate internal pressure.

Ignoring your breather filter maintenance is like skipping oil changes—it’s a disaster waiting to happen.

How Does an Air Filter Work?

Air filters act as a first line of defense against dust, dirt, and debris. Whether in diesel engines, air compressors, or HVAC systems, they ensure clean airflow, which is essential for fuel combustion, engine efficiency, and operator comfort.

How Long Do Air Filters Last?

It depends. A diesel engine air filter might last 500–1,000 hours, while a cabin air filter should be replaced every 12,000–15,000 miles. But if you’re operating in dusty environments, expect a much shorter lifespan. A clogged air filter can cause:

- Reduced fuel efficiency—a struggling engine burns more fuel.

- Decreased horsepower—restricted airflow means weaker combustion.

- Higher emissions—dirty filters lead to incomplete fuel burning.

The changing time of the air filter replacement could vary from equipment to equipment. If you want to know the best air filter changing solutions, click here: 8 Must-Know Signs of a Bad Engine Air Filter & Everything You Need to Know

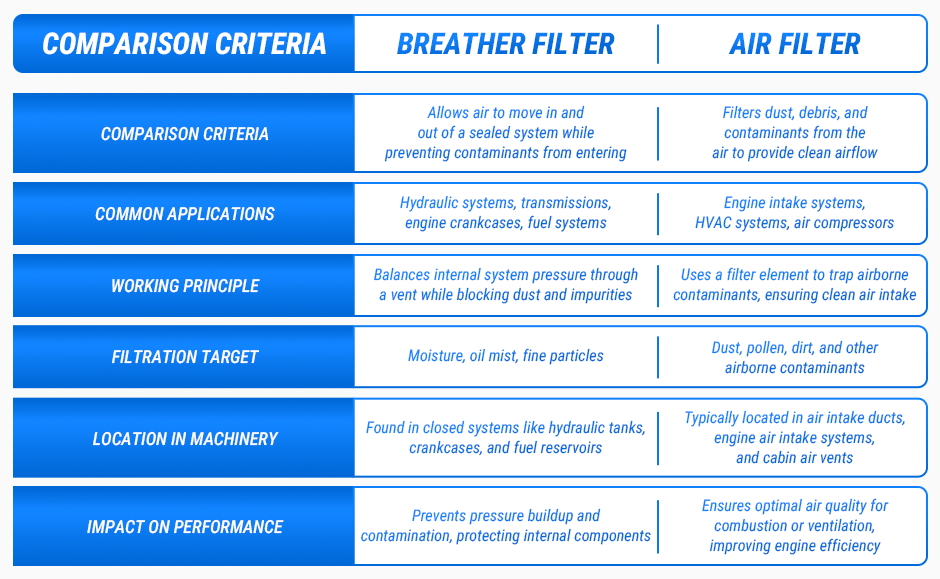

Breather Filter vs Air Filter: Key Differences

Alright, let’s break it down. Breather filters and air filters might sound like they do the same job, but trust me, they don’t. These bad boys serve totally different purposes under the hood, and knowing which one does what can save you a whole lot of headaches and repair bills.

A breather filter is like your machinery’s pressure regulator—it keeps things balanced and breathing easy inside sealed systems like crankcases, hydraulic tanks, and transmissions. Its main gig? Blocking moisture, oil mist, and dirt from sneaking in and wrecking internal components. If this filter gets clogged, you’re looking at pressure buildup, oil leaks, and potential seal failures—definitely not something you want messing with your equipment. As for lifespan, a breather filter typically needs a swap every 6 to 12 months, but if you’re running your machine in rough conditions, you might wanna check it sooner.

Now, an air filter plays an entirely different game. This one is all about keeping the air that enters your engine or HVAC system clean—think of it like a bouncer at the club, kicking out dust, dirt, and pollen before they can crash the party. A clogged air filter can choke your engine, leading to weaker horsepower, crappy fuel efficiency, and even higher emissions. Not ideal, right? To keep your engine running smooth and powerful, most air filters should be swapped every 500 to 1,500 hours, but again, if you’re working in dusty terrain, don’t push your luck—check it often.

At the end of the day, breather filters protect what’s inside, while air filters shield what goes in. Skip maintenance on either, and you’ll be burning cash on repairs before you know it. So, if you want your machinery to keep running like a beast, stay on top of your filter game!

Common Machinery That Uses Air Filters

- Bulldozers – Filters keep dust from clogging the engine.

- Forklifts – Clean air ensures smooth combustion.

- Generators – Stable air intake prevents performance drops.

When to Use Each Filter in Your Equipment

Still unsure which filter your machine needs? Here’s the breakdown.

Use a Breather Filter When:

- You’re dealing with sealed hydraulic systems.

- Your equipment has a crankcase ventilation system.

- You want to prevent moisture and pressure buildup in fluid reservoirs.

Use an Air Filter When:

- Your machinery has an internal combustion engine.

- You operate in dusty or high-debris environments.

- You want to extend engine life and improve fuel efficiency.

Using the wrong filter—or worse, neglecting them altogether—can mean costly repairs, unexpected downtime, and a machine that won’t perform when you need it most.

Conclusion

At the end of the day, breather filters vs air filters isn’t an either-or choice. Both play vital roles in keeping your heavy machinery in top shape.

- Breather filters protect sealed systems from pressure damage and contamination.

- Air filters ensure clean airflow for engine performance and efficiency.

At FridayParts, we’ve got your back. We offer a wide range of high-quality filters for all kinds of heavy equipment, including air filters, oil filters, and more, all at the best prices around. No matter the brand or model, you’ll find exactly what you need to keep your machinery running like a champ. So, why not take a minute to check out our collection?

Head over to FridayParts.com, browse our filters, and get your equipment ready to work hard without a hitch.