Tracked bulldozers can work in extreme conditions—pushing heavy loads, leveling surfaces, and driving through rough terrain. This power and stability came directly from the bulldozer track system and undercarriage. However, these moving parts also account for 20% of the total maintenance cost of the machine. Understanding how it works is the first step to low costs and extending the life of your equipment. In this guide, we will talk about each major component of the track system and provide practical maintenance tips.

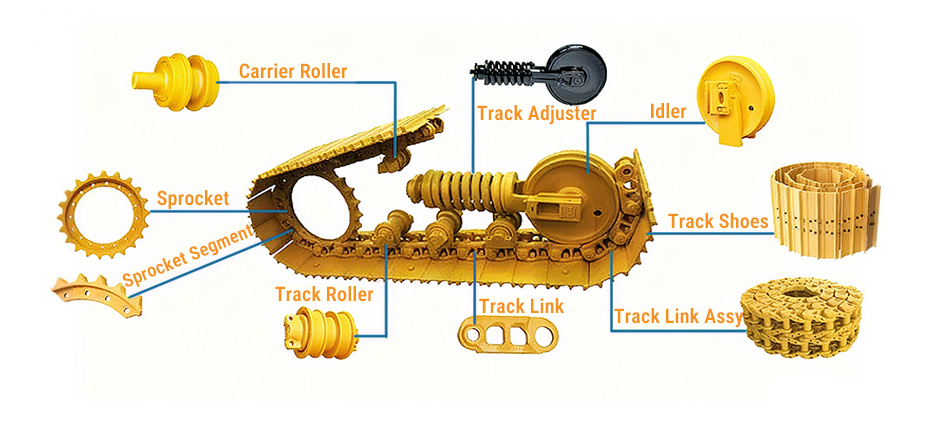

What are the Parts of a Bulldozer Track with Diagram?

To handle maintenance skills, you need to understand the structure of the undercarriage. It is not just a component, but a team of heavy components, providing propulsion, support, and stability. Let’s take a look at each key component.

Track

This is the part everyone sees, but its construction is more complex than it appears. The track assembly is the complete, continuous loop that contacts the ground.

Track Shoes: These are the individual metal plates that form the outer surface of the track. Their primary job is to provide traction and distribute the machine’s immense weight over a large surface area, reducing ground pressure. The raised bars on the shoes, known as grousers, are essential for gripping loose or slippery surfaces like mud, sand, and soil. The type and width of the track shoe should match the typical ground conditions you work in.

Track Links and Chain: The track shoes are bolted to the track links, which form the flexible backbone of the entire system. These links are connected by hardened steel pins and bushings, creating a chain that can articulate and wrap around the other undercarriage components. This chain bears the full weight of the machine and endures constant pulling forces from the final drive. The interface between the pins and bushings is a major point of internal wear.

Sprocket

The sprocket is the large, toothed gear located at the rear of the undercarriage. It is the only component that is directly powered by the engine (via the final drive). Its teeth engage with the bushings of the track chain, pulling it forward or backward to propel the machine.

Think of it like the gear on a bicycle that pulls the chain. As the sprocket turns, its teeth fit into the gaps in the track chain, driving the entire loop. Because of this constant metal-on-metal contact under extreme force, the sprocket’s teeth are a high-wear item.

Final Drive

Tucked safely behind the sprocket is the final drive. This is the true powerhouse of the undercarriage. It is a compact, powerful gearbox that takes high-speed, low-torque power from the machine’s hydraulic system and converts it into the low-speed, high-torque rotational force needed to turn the sprocket. This torque multiplication is what gives a bulldozer track its incredible pushing power. The final drive is a sealed unit filled with oil and contains a set of planetary gears to achieve this gear reduction.

Front Idler and Recoil Spring

At the front of the undercarriage, directly opposite the sprocket, is the large, smooth wheel known as the front idler. Its main job is to guide the track chain back up and around towards the top. However, it works as part of a critical team with the recoil spring and track adjuster. This entire assembly absorbs heavy impacts from rocks and uneven ground, protecting the rest of the undercarriage. More importantly, the track adjuster uses hydraulic pressure to push the idler forward or backward, setting the correct track tension.

Upper and Lower Rollers

Lining the bottom and top of the track frame are a series of smaller wheels called rollers. They serve two distinct but equally important functions:

Lower Rollers (Track Rollers): These are located on the bottom of the frame and run along the track chain’s inner rail. They bear the entire weight of the bulldozer and are responsible for keeping the machine level and stable.

Upper Rollers (Carrier Rollers): These are positioned on top of the frame. Their sole purpose is to support the weight of the upper section of the track, preventing it from sagging and hitting the track frame.

Common Bulldozer Track & Undercarriage Problems

Bulldozer parts on the undercarriage suffer constant impact, high friction of the rotating parts, and heavy-duty parts, which require constant monitoring and regular maintenance.

Improper Track Tension (Too Tight or Too Loose)

This is the most common and damaging issue. Over-loose tracks slip, causing excessive wear of sprocket teeth and track bushings. Worse, the track may also “derail” or disengage from the idler or sprocket. Over-tight tracks create great friction and strain on every moving part (idler, runner, sprocket, and final drive bearing). It requires more engine power to move, consumes more fuel, and significantly accelerates wear across the entire system.

Accelerated and Uneven Component Wear

All undercarriage parts are designed to wear out eventually, but certain conditions can speed up the process significantly. Operating in highly abrasive materials like sand, rock, or corrosive soil acts like sandpaper on all moving parts. Other causes include consistently operating at high speeds (which generates more heat and friction) or always turning the machine in the same direction, which places uneven stress on one side of the undercarriage.

Final Drive Failure

A failing final drive is one of the most expensive undercarriage repairs. Failures are often caused by contaminated gear oil from a leaking seal or simply from the internal gears and bearings reaching the end of their service life. A grinding noise, loss of power on one side, or visible leaks are all urgent warning signs.

Broken or Weakened Recoil Springs

The recoil spring is under immense pressure. A sudden, severe impact can cause it to break catastrophically. More often, it simply weakens over time, losing its ability to maintain proper track tension and absorb shocks. This leads to the same problems as a loose track and puts the operator at risk.

Track Misalignment and Derailment

If you notice the track isn’t running straight on the rollers and idler, you have a misalignment issue. This is often a symptom of another problem, such as worn idler flanges or broken rollers. Misalignment causes severe, uneven wear on the sides of the rollers and track links and is a primary cause of derailment.

Impact Damage and Overloading

Operator habits play a huge role in undercarriage life. Dropping the machine off ledges, hitting large rocks at speed, or consistently exceeding the machine’s load capacity sends massive shockwaves through the entire system, leading to cracks, broken seals, and premature failure of all components.

Bulldozer Track Maintenance Tips

The good news is that most major failures can be avoided with a consistent maintenance routine. Proactive care is far cheaper than reactive repairs.

| Inspection Cycle | Key Tasks | Tools Needed |

|---|---|---|

| Daily | Clean out mud, rocks, and debris from the undercarriage. Visually inspect for leaks or loose bolts. Check track tension (sag). | Shovel, pressure washer, pry bar |

| Weekly | Check the torque on all visible bolts, especially on the track shoes and rollers. | Torque wrench |

| Periodic | Measure the wear on key components like grousers, bushings, and roller diameters. Check final drive oil levels. | Calipers, depth gauge, appropriate wrenches |

Bulldozer Undercarriage Parts for Your Models

When routine maintenance does not meet the need, it is essential to get the right parts quickly to replace them. FridayParts’ extensive selection covers many heavy equipment brands, and we focus on providing OEM-quality and a wide selection of undercarriage parts to ensure the satisfaction of every customer. From a single roller to a complete final drive assembly, make sure you can find the bulldozer track parts you need, and get back to work quickly!