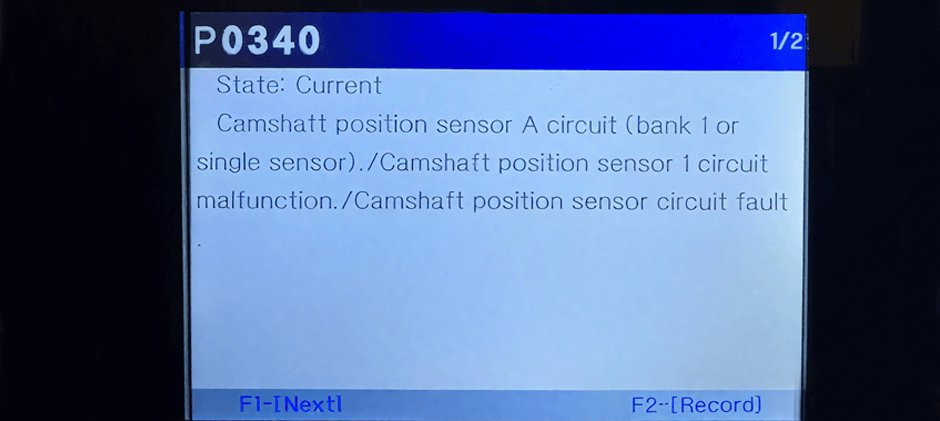

When the check‑engine light flashes and your diagnostic tool reads P0340 code, you’re not alone. This error appears frequently on light‑duty diesel trucks — such as Ford F‑series, Dodge Ram Cummins, or Toyota Hilux — but the same underlying issue also exists in off‑road machinery like excavators and loaders using similar electronic fuel management systems. The P0340 code identifies a fault in the camshaft position sensor circuit — a small component whose failure can cause sudden stalls, misfires, or even no‑start conditions. In this guide, we’ll explain what that sensor really does, why you might still see the code after replacing it, and how to perform a proper camshaft position sensor replacement to restore reliable power and timing to your heavy equipment.

Troubleshooting Summary

| Symptom | Likely Cause | Solution |

|---|---|---|

| Persistent P0340 code | Code memory not cleared | Manually clear with the scanner |

| The engine stalls randomly | Loose or contaminated connector | Clean and tighten |

| The new sensor didn’t fix the issue | Wrong sensor circuit or poor part quality | Match the proper OEM number |

| Uneven idle after install | ECM needs relearn | Perform a reset or calibration |

| Hard start in cold conditions | Weak magnetic pickup | Replace the sensor and inspect the tone wheel |

What Does the Camshaft Position Sensor Do?

A position sensor for the camshaft measures the rotation speed and angle of the camshaft and sends that information to the Engine Control Module (ECM). The ECM uses those signals to manage injector pulse timing and ignition. In heavy‑equipment diesel applications, fuel delivery timing and valve sequencing must remain precise, especially under varying loads and torque demands.

Typically, this sensor employs a Hall‑effect element, which reacts to a magnetic tooth on a camshaft gear. Every pulse generated is translated into an electrical wave that the ECM interprets. Once the ECM aligns the camshaft’s data with the crankshaft’s sensor output, it ensures perfect synchronization — necessary for both cold starts and heavy hauling.

Without a functioning camshaft position sensor, your off‑road engine may display:

- Hard starting or intermittent stalling

- Erratic idling or rpm surges

- Sudden loss of power during heavy load

- Diagnostic code P0340 or similar camshaft‑related errors

In short, it’s a small sensor with a huge job — one that keeps your excavator, loader, or dozer firing on rhythm.

Why Do I Still Get a P0340 After Replacing It?

You replaced the sensor, yet the check‑engine light remains. Many operators experience the same cycle: install a brand‑new camshaft position sensor, then still pull a P0340 code after startup. Why? Several factors can cause that:

1. Fault Not Cleared

The ECM doesn’t automatically clear stored codes just because you replaced the pa

rt. After installation, the code must be cleared manually — either with a diagnostic scanner or a key‑cycling procedure shown in your service manual.

If you don’t clear it, your warning light will persist even if the issue is solved.

2. Replaced the Wrong Sensor

Some off‑road diesel engines employ two sensors (intake and exhaust cams). The A‑circuit refers to one camshaft, while the B‑circuit governs another. If the wrong sensor was changed, the ECM still detects the fault.

3. Incorrect Installation or Wiring

Check the connector fit, terminal corrosion, and harness routing. Heavy machinery often operates in dirty and humid environments, and poor contact or pin misalignment can instantly retrigger the fault.

4. Defective or Incompatible Part

Not all aftermarket parts hold the same calibration tolerances. A sensor outside its voltage range can still cause a P0340 code misfires. Choose high‑quality, tested electrical parts compatible with your engine’s ADEM, Cummins, or J1939 control systems.

5. Timing or ECM Synchronization Issues

If both the camshaft and crankshaft data are out of sync, even a new sensor can flag the same warning. This often occurs when timing gear wear, slack timing chains, or poor installation affect alignment. Performing a “relearn” process with a scan tool helps the ECM adjust.

How to Fix Error Code P0340?

Mechanically, the P0340 code describes a fault in the “Camshaft Position Sensor Circuit.” That means the ECM is losing contact with the sensor signal, voltage reference, or circuit ground.

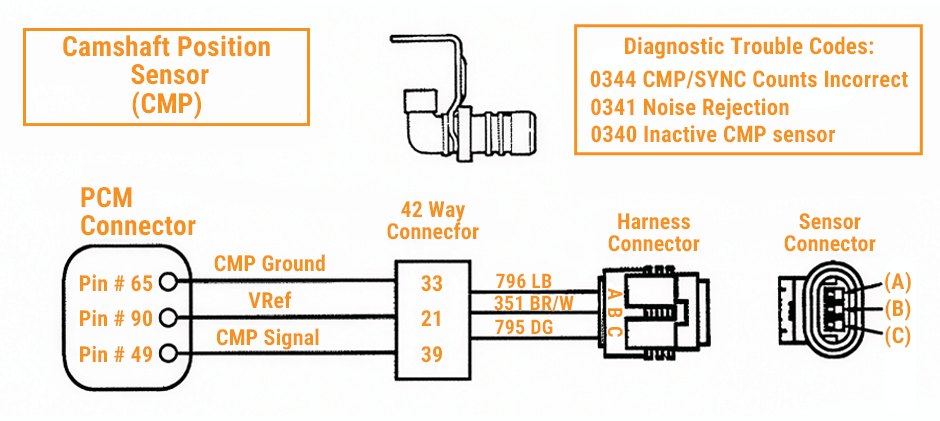

The standard electrical diagram (shown above) depicts a 3‑wire connection:

- VRef (5 V) — provides constant reference power.

- Signal — pulses sent back to ECM.

- Ground — completes the circuit.

A bad voltage ground, damaged harness, or open circuit can generate P0340 code readings. Heavy‑duty vibrations or oil infiltration near the timing case can accelerate connector wear.

Basic Troubleshooting

- Check Power and Ground — Use a multimeter to confirm 5 V supply and ground continuity at the connector.

- Inspect Wiring — Look for pinched, burnt, or oil‑soaked wires along the valve cover harness.

- Check for Synchronization Errors — Using a diagnostic tool, observe the engine’s live data. A mismatch between cam and crank signals indicates mechanical timing issues.

- Relearn Procedure — After replacing the sensor, some ECMs require a learning process to re‑establish base timing.

When in doubt, consult your machine’s service data or an experienced technician. But most issues trace to poor contact or skipped relearn steps rather than major ECM faults.

If you suspect the actual sensor’s internal circuit, review our detailed diagnostic testing guide for a malfunctioning position sensor, which explores how to verify waveform outputs and voltage transitions for off‑road engines.

How to Replace the Camshaft Position Sensor Right?

Performing a camshaft position sensor replacement correctly can save hours of downtime. Follow these streamlined steps for off‑road machinery:

Step 1 – Locate the Sensor

Depending on the engine layout, find the sensor mounted near the cam gear cover or valve head. On most heavy diesels, it’s fixed by 1–2 bolts and connected via a sealed plug.

Step 2 – Disconnect the Power

Turn off the ignition and disconnect the battery to eliminate voltage spikes.

Step 3 – Unplug and Remove the Old Sensor

Release the clip on the connector. Use a small socket to remove fasteners carefully — avoid dropping them into the housing. Pull the sensor straight out.

Step 4 – Inspect Related Components

Check that the mounting bore is clean, without metal debris or oil sludge. Check the harness end and nearby electrical parts — a brittle harness can mimic sensor failure.

Step 5 – Install the New Sensor

Apply a thin film of oil to the O‑ring, insert the sensor evenly, and tighten bolts gently until snug. Don’t over‑torque. Plug the connector back.

Step 6 – Relearn or Reset the ECM

Modern heavy equipment ECUs often require a calibration known as “Cam‑Crank Relearn.” Connect your scan tool, select the relearn function, and let the software align cam and crank positions. Alternatively, idle and run through operating cycles (load, idle, deceleration) to allow self‑learning.

If the P0340 code clears and the idle smooths out, your replacement succeeded.

Tips for Replacing Camshaft Position Sensors

- Always compare new and old sensors by shape and connector style before installation.

- Keep the area free from dust – contamination affects magnetic readings.

- Use dielectric grease on connectors in wet work sites.

- Confirm reference and signal voltages before re‑assembly.

- When replacing, inspect related electrical parts such as crank sensors, wiring looms, and ECM fuses.

Proper preparation reduces repeat failures and keeps your heavy‑equipment fleet running reliably.

Summary

If you’re looking for durable sensors and harness components that won’t fail under vibration or mud, FridayParts provides premium aftermarket solutions. Our inventory includes thousands of compatible camshaft position sensor replacement options for loaders, excavators, and other off‑road units — combining OEM‑level accuracy with better value. Order online and keep your machines moving when every minute counts.