Unlike engine oil or hydraulic fluid in mechanical equipment, brake fluid doesn’t consume or burn off. It works quietly in a sealed system, leading many owners to believe it lasts forever. But that’s wrong. With respect to heavy-duty equipment, the neglect of brake fluid will directly imperil the safety of the operator and the well-being of the machine. This compendium shall serve to explicate all matters about said brake fluid—its operational function, its mode of degradation, and, of paramount importance, the frequency with which it must be replaced to ensure the safety and reliability of your equipment.

What Happens to Brake Fluid Over Time?

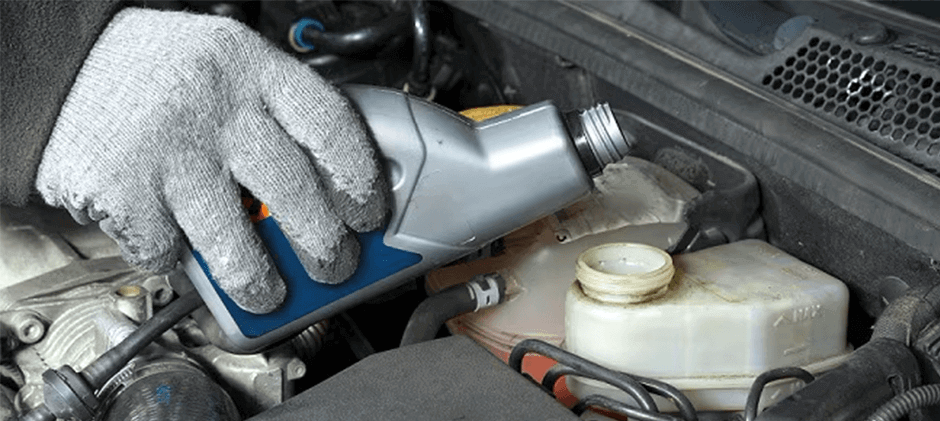

Braking fluid is a kind of hydraulic oil, meaning the primary function is to transform the power pressed by the foot on the brake pedal into pressure, thereby activating the braking components on the wheels. However, most common braking fluids (DOT 3, 4, and 5.1) all possess a chemical property that has both advantages and disadvantages: hygroscopicity. If hydraulic oil is not replaced, water content will accumulate with the passage of time. Even in the so-called sealed system, water can infiltrate through microscopic pores in the brake hoses and seals, and moreover, it enters each time the master cylinder reservoir cap is opened.

Here’s what happens as moisture builds up:

- Lowered Boiling Point: Fresh and immaculate brake fluid possesses a highly elevated boiling point, enabling it to withstand the elevated temperatures generated during the actuation of braking mechanisms. Conversely, the boiling point of water is of a significantly lower magnitude (212°F / 100°C). In tandem with the incremental augmentation of moisture content within said brake fluid, the aggregate boiling point of said brake fluid is subject to a precipitous decline.

- Corrosion: Water is the enemy of the metal components inside your braking system. The absorbed moisture leads to internal corrosion, which can rust and damage the most critical parts of the system. This includes the finely machined bores of the Brake Master Cylinder, caliper pistons, and the inner walls of brake lines.

This degradation isn’t just theoretical; it directly impacts your machine’s ability to stop safely.

How Long Does Brake Fluid Last?

In a perfectly controlled laboratory environment, brake fluid could last for many years. But your heavy equipment doesn’t operate in a lab. It works in dust, mud, rain, and extreme temperatures. For off-road machinery, the lifespan of brake fluid is significantly shorter than in a passenger car.

Generally, brake fluid can absorb enough moisture to become unsafe within 2 to 3 years. However, this timeline can be much shorter depending on the operating conditions. A machine that sits in a humid environment will absorb moisture faster than one stored in a dry climate, even if it isn’t being used. Similarly, a machine that works constantly in wet and muddy conditions is at a higher risk of accelerated contamination. The key takeaway is that time is as much an enemy to your brake fluid as operating hours are.

The Importance of Using the Correct Brake Fluid Type

Beyond replacement frequency, using the correct brake fluid specification is critical for both performance and safety. Every machine’s braking system is engineered with a specific fluid type in mind, determined by its seals, materials, and operating pressures. Mixing incompatible fluids—such as glycol-based DOT 3/4/5.1 with silicone-based DOT 5—can cause seal swelling, internal leaks, and complete brake failure. Always verify your machine’s service manual and label markings on the reservoir before topping up or replacing fluid. For fleet maintenance managers, standardizing on the proper specification across all equipment helps simplify procurement and prevent costly mix-ups.

How Often to Change Brake Fluid?

This represents the most pivotal inquiry, the resolution of which is not a mere singular numerical value. Even though the common guiding principle for passenger vehicles is the periodic replacement every two-year interval, with respect to heavy-duty off-road machinery, a more meticulous and condition-based maintenance methodology is of paramount importance for the purpose of guaranteeing safety and precluding costly mechanical malfunctions.

The fundamental recommendation consists of the replacement of said brake fluid every two-year interval, or every 2,000 hours of operational time, or every 24,000 to 30,000 miles of travel distance, contingent upon whichever of the aforementioned conditions is first attained. However, you should consider this the absolute maximum interval.

Your actual service frequency should be adjusted based on the following critical factors:

- Manufacturer’s Service Manual: This is your number one source of truth. The engineers who designed your machine provide specific maintenance schedules. Always start by consulting your operator’s or service manual for their recommended interval.

- Operating Environment: This is arguably the biggest factor for off-road equipment.

- High Humidity/Wet Conditions: If your machinery operates in rainy, humid climates or frequently works in mud and water (like in pipeline construction or forestry), you should consider annual brake fluid changes.

- Dusty and Dirty Conditions: Fine dust can work its way past seals and contaminate the fluid. Equipment used in quarries, agriculture, or earthmoving should have its fluid inspected more frequently.

Workload and Braking Demands: How hard does your machine work its brakes?

- Steep Terrain: A haul truck, dozer, or loader operating on steep grades relies heavily on its brakes, generating immense heat. This heat can bring contaminated fluid to a boil much faster.

- Repetitive Braking: Machinery used in tasks that require constant, repetitive braking (like a forklift or a yard loader) puts more stress and heat on the system.

Type of Brake Fluid: Your machine will specify a certain DOT (Department of Transportation) fluid.

- DOT 3 & 4: These are the most common glycol-based fluids. DOT 4 has a higher boiling point than DOT 3, but also tends to absorb moisture slightly faster.

- DOT 5.1: This is also glycol-based and has an even higher boiling point, designed for high-performance applications. It is compatible with DOT 3 and 4 systems.

- DOT 5: This is silicone-based and does not absorb water. It is NOT compatible with systems designed for glycol-based fluids. Never mix them.

| Factor | Standard Interval | Aggressive Interval |

|---|---|---|

| Time | 2-3 Years | 1-2 Years |

| Operating Hours | 2,000 Hours | 1,000 – 1,500 Hours |

| Driving distance | 30,000 miles | 24,000 miles |

| Environment | Clean, Dry | Wet, Humid, Dusty |

| Workload | Light, Flat Ground | Heavy Loads, Steep Grades |

Ultimately, the best strategy is proactive inspection. Treat your brake fluid check as a standard part of your major service intervals, alongside checking your brake pads or the condition of your brake shoes.

What Happens If Brake Fluid is Never Changed?

Ignoring your brake fluid is a gamble with severe consequences. The gradual degradation of the fluid can lead to sudden and catastrophic failure, often at the worst possible moment.

Here’s what you are risking:

- Brake Fade and Vapor Lock: This is the most immediate danger. Imagine you are driving a loaded dumper down a long, steep haul road. The brakes get extremely hot. If your brake fluid is contaminated with water, that heat can cause the water to boil and turn into steam (vapor). Since vapor is compressible and fluid is not, pressing the brake pedal will simply squeeze the vapor bubbles instead of applying force to the brakes. The pedal will feel spongy and may go all the way to the floor with little to no stopping power. This is known as brake fade, and it can be terrifying.

- Complete Brake System Failure: The corrosion caused by moisture doesn’t just happen overnight. It slowly eats away at the internal components of your entire braking system. This can lead to:

- Seals in the master cylinder or wheel cylinders are failing, causing leaks.

- Caliper pistons are seizing in their bores, causing brakes to drag or fail to apply.

- Brake lines rusting from the inside out, potentially bursting under pressure.

- Expensive, System-Wide Repairs: A simple brake fluid change might cost a couple of hundred dollars. Replacing a corroded master cylinder, calipers, and brake lines can run into the thousands, not to mention the costly downtime for the machine. Neglecting this one simple fluid can easily destroy all the major brake system parts over time.

How to Tell if My Brake Fluid Needs Changing?

In addition to the rigorous adherence to the replacement schedule, there exist a number of readily perceptible indications that your brake fluid has suffered detriment, necessitating immediate remediation.

Visual Inspection of the Fluid

One should commence by opening the brake fluid reservoir. Fresh brake fluid typically presents itself in a transparent or pale amber hue. If the liquid shows a deepened color, turns turbid, or contains floating particulates, it clearly manifests contamination, and one must promptly replace it.

Flaccid or Spongy Brake Pedal

This is a typical indication of the presence of gaseous or vaporous components within the brake lines, which is often directly consequential upon the boiling of aged, water-contaminated brake fluid. When the pedal is depressed, one may perceive a sensation of flaccidity or a sinking towards the floor.

Augmented Braking Distance

Should it be brought to your attention that the machine requires an extended duration to achieve complete cessation of motion, it is indicative that the braking system is not operating at its full efficacy. Worn brake fluid is a frequent perpetrator in such circumstances.

ABS or Brake Warning Illuminator

Modern heavy-duty equipment commonly includes sensory apparatus that can discern anomalies within the anti-lock braking system (ABS) or the foundational braking system. If a brake-related warning illuminator emerges upon the dashboard, one should therefore conduct an immediate and comprehensive examination of the entire system, including the fluid.

Ascertainment of Moisture Content

The methodology of the most scientific nature for confirmation is to subject the fluid to a test. A qualified technician can measure the moisture content within a matter of mere seconds by employing an electronic brake fluid tester. A reading that attains or surpasses 3% is demonstrative of the fluid being in an unsafe state, and its immediate replacement is mandatory.

In Summary

Considering the extreme conditions endured by off-road equipment, please replace your brake fluid at least every 2-3 years, depending on the situation. Don’t neglect brake fluid inspection and replacement. Taking proactive measures based on operating hours and operating conditions will ensure safe equipment operation and avoid catastrophic and costly failures. When you have any maintenance needs, Friday Parts offers a large selection of high-quality, affordable aftermarket brake parts to ensure you maintain your equipment with the highest safety standards.