Whether it is heavy-duty equipment or road vehicles, the engine is full of moving parts, and these moving parts rely on sufficient engine oil to operate normally. Most equipment also consumes a small amount of oil during operation. Lack of engine oil can lead to catastrophic engine failure; therefore, regular inspection of oil consumption is very important. Otherwise, it may result in expensive repair costs. The good news is, prevention is very simple. By learning how to correctly check the oil, read the engine oil dipstick, and refill on time, most serious problems can be avoided. This guide will lead you through each step, ensuring you grasp the necessary knowledge and keep your equipment running strongly.

Why Do You Need to Check the Oil?

Within the harsh environment of off-road machinery, the engine oil performs multiple critical functions, and regular inspection becomes the only way to ensure its normal operation. The primary role of oil is lubrication, creating an important film to prevent the direct contact of metals and catastrophic wear. It also possesses the capacity to control the heat, absorbing the high temperature produced by the engine, thus preventing overheating under heavy load. During the circulation, the oil can adsorb the soot and dust from the working site, so that it cleans the engine. Therefore, the regular inspection is not only the confirmation of the level, but also an important diagnostic method. The decrease in oil level may indicate leakage or consumption, while the milky or coarse oil may, before the complete failure of the engine, reveal the severe internal problems, such as the leakage of coolant.

Do not merely regard the oil as the lubricant, but rather regard it as the diagnostic instrument. The level and the condition of the engine oil dipstick can reflect, more clearly than almost any other simple check, the health status of the engine.

How to Check Your Engine Oil Level?

The inspection of the oil level is, in essence, swift and simple, yet the correctness of operation becomes indispensable if one seeks an accurate reading. Please adhere to the following procedure, which has been especially adjusted to the demands of heavy machinery.

Step 1: Prepare the Machine and Your Tools

At the outset, position the machine upon a flat terrain. Should the inspection occur upon a slope, the reading will deviate, for the oil tends to accumulate toward one side of the sump. Engage the hand brake with firmness and extinguish the engine. For the attainment of the most precise reading, numerous heavy-equipment manufacturers recommend examining the oil level subsequent to the warming of the engine, though not immediately after the shutdown.

A prudent rule suggests waiting 15–20 minutes following the cessation of the engine. This interval permits the oil, which had been circulating within the engine, to return toward the sump, whilst preserving a sufficient warmth therein so the oil may flow with proper steadiness. Be sure to consult the operator’s manual, wherein lie the precise instructions pertinent to your machine. Furthermore, it is necessary to take from the hand tools a clean, lint-free cloth or a paper towel.

Step 2: Locate and Clean the Dipstick Area

Ordinarily, the engine oil dipstick bears a handle of vivid hue (most often yellow or red), perhaps adorned with the emblem of an oil vessel. Amidst the dusty worksite, the precinct encircling the dipstick tube may be laden with powder and fragments. Before the act of extracting the dipstick, one must, with diligence, wipe thoroughly both the handle and the region about the base of the dipstick tube. This indispensable procedure shall avert the descent of dust into the engine at the moment of withdrawal.

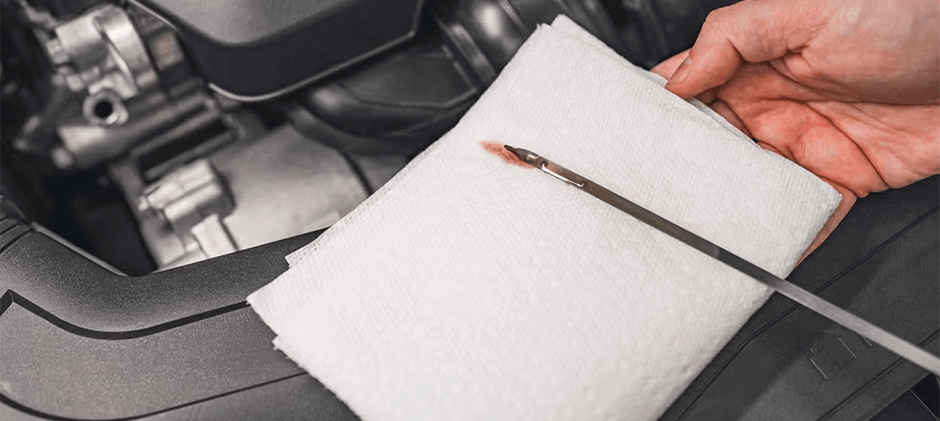

Step 3: Perform the First Pull and Wipe

Pull the dipstick all the way out. The first pull is not for taking a reading, as oil will have splashed onto the stick during operation. Use your clean rag to wipe the entire length of the dipstick clean, from the handle down to the tip.

Step 4: Reinsert for the Reading

Slowly and carefully insert the clean dipstick back into its tube. Make sure it is pushed all the way down until the handle is fully seated. If it doesn’t go in smoothly, do not force it; pull it out, rotate it, and try again. An improperly seated dipstick will result in an incorrect reading.

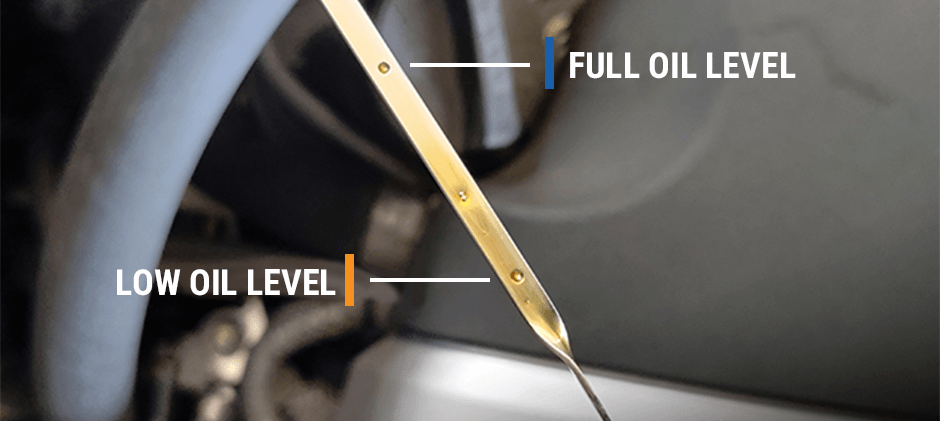

Step 5: Take the Final Reading

Pull the dipstick out a second time. This time, hold it horizontally to prevent the oil from

running up or down the stick. Now you can observe the oil level and its condition.

How to Read Dipstick Oil Levels?

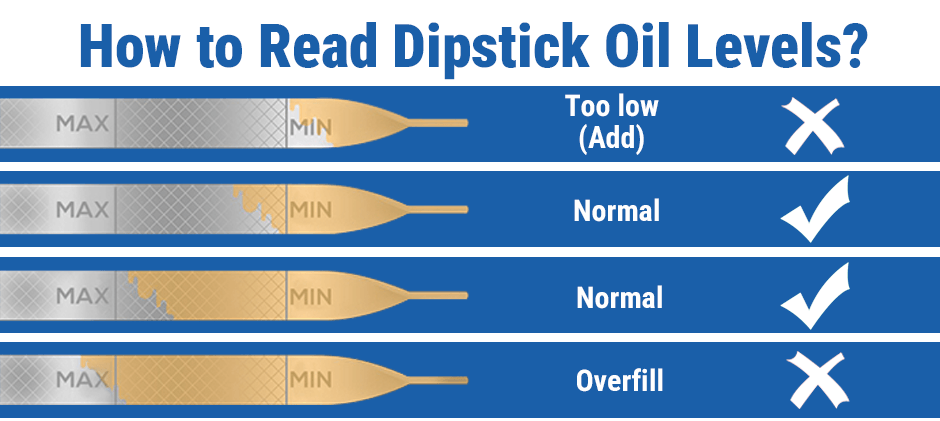

The markings on the engine oil dipstick are contrived with simplicity and lucidity. Although the particular inscriptions may present divergence between diverse manufacturers, they yet conform to the identical governing principle. What follows is the manner in which thou mayest interpret that which thine eyes encounter, as though thou wert perusing a pictorial manual.

Level 1: Dangerously Low (At or Below the “LOW” Mark)

If the oil quantity is situated at or below the lowest indication (commonly inscribed as “LOW” or “MIN”), then the oil condition can be considered exceedingly insufficient. One ought to, before reinitiating the engine’s operation, immediately pour in the correct category of lubricating fluid. Should the oil remain at such a position, the engine may encounter severe impairment due to the deficiency of lubrication.

Level 2: Add (Between the Marks)

The interval between the “LOW” and “FULL” indications constitutes the secure operational boundary. If the oil quantity occupies such a region, the engine does not instantaneously reside within peril; nevertheless, it is preferable to elevate the oil condition to the “FULL” mark. Within the majority of engines belonging to heavy-duty equipment, the distance between these two indications usually signifies one to two quarts of lubricating fluid.

Level 3: Full (At or Near the “FULL” Mark)

This is considered the ideal oil level. If the trace of oil terminates exactly at the “FULL” mark or slightly lower, it indicates the engine oil quantity remains correct. No further action is required.

Level 4: Overfilled (Above the “FULL” Mark)

If the oil level surpasses the uppermost indication (generally denoted as “FULL” or “MAX”), it means the oil exists in an excessive condition. Such a circumstance is regarded as dangerous. Too much oil will be agitated by the crankshaft into a foamy substance, resulting in insufficient lubrication and potentially leading to engine impairment. When the overfilling is discovered, it becomes necessary to discharge a portion of the oil.

Beyond the Level: Reading the Oil’s Condition

The condition of the lubricant itself possesses equal significance as the mere height of the level. One may employ the thumb and forefinger to acquire a small portion of oil.

- Color: New, clean oil is a translucent amber color. In a diesel engine, it is perfectly normal for the oil to turn black relatively quickly due to soot. This is not a sign that the oil is bad. However, if the oil looks milky or creamy, it is a sign of coolant contamination and requires immediate professional attention.

- Consistency: Ideally, the oil ought to convey a sensation of smoothness and fineness. If it imparts a gritty impression to the touch or minute metallic fragments are visibly suspended, this may indicate internal attrition of the engine.

- Odor: Should the lubricant exude an intense fragrance resembling diesel, this could indicate a malfunction within the fuel injection apparatus, whereby fuel dilutes the oil, thus diminishing its lubricative capacity.

If your engine oil dipstick is broken, bent, or hard to read, it’s a critical part to replace. An inaccurate reading is as bad as no reading at all. You can find high-quality, affordable aftermarket replacements for a wide variety of heavy equipment brands.

How Often Should You Check My Oil Levels?

For off-road machinery, checking frequency should be based on operating hours, not miles. The harder the machine works, the more often you should check.

| Usage Scenario | Recommended Checking Frequency |

|---|---|

| Standard Operation | Daily, before starting the first shift. |

| Light or Intermittent Use | At least once a week. |

| Severe Duty (Heavy loads, extreme heat, very dusty conditions) | Daily, consider a mid-shift check if operating continuously. |

| Before a Long or Critical Job | Always check before starting, regardless of the last check. |

Creating a routine is key. Making the oil check a non-negotiable part of your pre-start inspection checklist is the best habit you can form to ensure engine longevity.

Keep Your Engine Running with the Right Parts

Regularly checking your engine oil is a simple task that pays huge dividends in reliability and engine life. To engage in the periodical inspection of the engine oil may seem like a task of simplicity; nevertheless, it possesses the capacity to remarkably augment both the reliability and the longevity of the engine. It serves as the foremost line of defense to avert costly repairs and unforeseen cessation of machinery. In the circumstance where, during the inspection, one perceives a rupture of the dipstick, a leakage of the sealing ring, or any other anomaly, the immediacy of treatment becomes of utmost necessity. There exists no compulsion to rely solely upon the exorbitant parts of the dealership. The trustworthy aftermarket provider, namely FridayParts, is capable of rendering with modest pricing high-quality and durable components, whilst simultaneously assuring extensive compatibility with the principal brands of heavy-duty equipment.