From dump truck to mighty wheel loader, the lighting of modern heavy gear groweth ever more intricate. Amidst its many switches and signs, two are often mistaken: Daytime Running Light (DRL) and headlights. Though seeming alike, they are not the same, and to misuse them imperils safety. This present guide shall unfold in detail the significance of DRL and headlight, the distinctions that separate them, and the season when they are to be employed on off-road machinery.

What are DRLs and Headlights?

While both are forward-facing lights, they are designed for opposite purposes. Let’s define each one in the context of a heavy-duty work environment.

What are Daytime Running Lights (DRLs)?

The Daytime Running Lights are a kind of relatively low-intensity light, which shall be ignited automatically once the engine of the machine is in operation. Its sole function lies in rendering your massive machine more easily perceived by others during the hours of daylight.

- Their Purpose is Conspicuity: one may conceive the DRL as a signal that proclaimeth “Lo, I am here.” Amidst a construction site, busy, dusty, or entangled in disorder, they may aid other equipment operators and ground personnel to behold your machine more swiftly and with greater clarity, thereby markedly diminishing the hazard of collision.

- Off-Road Context: ye shall often behold DRL upon mobile equipment which is in frequent travel or at higher speeds, such as articulated dump trucks, great wheel loaders, scrapers, and mining trucks. Yet upon excavators, bulldozers, or compactors—which are more fixed or of slow motion—DRL are not commonly beheld, forasmuch as the principal task of such devices is not continual driving.

- They Don’t Help You See: one must never bear in mind that the Daytime Running light is contrived not for the purpose of illuminating the path before you or the working ground. Its brightness sufficeth not such a burden.

What are Headlights?

The headlight is the principal system of illumination of high intensity on the equipment. Its function stands in utter contrariety to that of the Daytime Running Light (DRL): it is devised for the purpose of assisting the operator in discerning the circumstance situated before the machine.

- Their Purpose is Illumination: the headlight doth emit a mighty and governable beam, whereby in the midst of darkness or adverse weather (as tempestuous rain, heavy snow, or dense fog), the transport roads, the loading face, the stockyard, and the general working domain may be rendered visible.

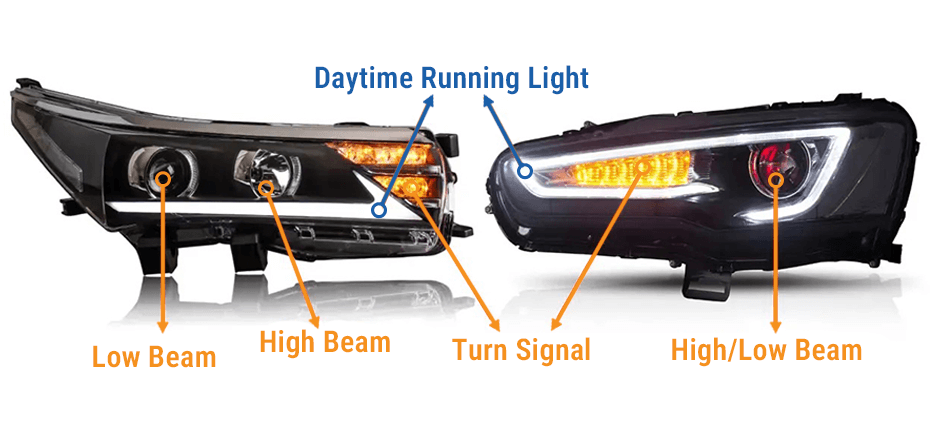

- Two Main Functions: every standard headlight possesses at least a pair of modes:

- Low Beams: it provides a breadth of illumination at near distance, with a sharp termination at the summit of the beam, lest the eyes of other operators be offended with glare.

- High Beams: when no other person is situated ahead, it send forth a narrow yet vehement ray to maximize visibility at distances afar.

Are They the Same?

The answer is an emphatic no. Although both are mounted upon the anterior of the machine, yet regarding function, contrivance, or efficacy, they partake scarcely of any commonality. To confound one with the other may conduce to perilous circumstances.

Key Differences Between DRLs and Headlights

Let’s dive into the five core differences that separate these two critical safety systems.

1. Primary Function: To Be Seen vs. To See

This is the distinction of utmost significance.

- DRLs exist purely for the elevation of being visible. Their mission resides in permitting ground personnel to perceive your fifty-ton loader advancing amidst dust, or in allowing fellow dump truck operators to discern your approach to a junction. They are not designed for the operator to acquire clearer sight.

- Headlights, conversely, are entirely for the operator’s visibility. They cast illumination upon the path, permitting one to detect menaces such as potholes, debris, or pedestrians, and thereby traverse in darkness with safety.

2. Brightness and Intensity

The difference in light output is massive.

- DRLs are of diminished brightness. Commonly, they generate between four hundred and seven hundred lumens, sufficient merely to be observed beneath daylight without inducing distraction.

- Headlights, in contrast, are of elevated brilliance. A standard halogen low beam delivers approximately one thousand lumens, whilst contemporary LED low beams may ascend to two thousand lumens or beyond. High beams may with ease surpass three thousand five hundred lumens, casting radiance upon objects hundreds of feet distant.

3. Beam Pattern and Direction

This, verily, doth manifest the pivotal divergence of their appointed function.

- DRLs diffuses a radiance both ample and scattered, its effulgence dispersed without allegiance unto any singular direction; its sole intent resideth in the mere evocation of a visible gleam from the forepart of the machine.

- The befitting headlight, contrariwise, standeth as a delicate contrivance of optical precision. By mirrors and by lenses it composeth a beam most rigorously ordained. The low beam revealeth a lucid and horizontal “termination line,” whereby the brilliance trespasseth not into the gaze of an oncoming operator; whilst the high beam concentrateth itself into a contracted “hot spot,” ordained for projection unto distances remote.

4. Activation and Control

How the lights turn on is another key differentiator.

- DRLs are almost always automatic. They activate as soon as the engine is started and turn off or dim when the main headlights are turned on. No operator input is required.

- Headlights require manual activation by the operator via a switch or dial. Some advanced machines may have an “auto” setting that uses a sensor to turn them on in low-light conditions, but the operator always has ultimate control.

5. Rear Light Activation

This is a crucial safety point that is often overlooked.

- DRLs typically do not activate any other lights on the machine. When your DRLs are on, your rear taillights are off.

- Headlights are always wired to activate the rear red taillights simultaneously. This ensures your machine is visible from both the front and the back in low-light conditions.

Here is a table summarizing these key differences:

| Feature | Daytime Running Lights (DRLs) | Headlights |

|---|---|---|

| Primary Function | Make the machine visible to others | Help the operator see the road/area |

| Brightness | Low intensity (400-700 lumens) | High intensity (1,000-3,500+ lumens) |

| Beam Pattern | Wide, scattered, unfocused | Controlled, focused, with a sharp cutoff |

| Activation | Automatic with engine start | Manual (or automatic via sensor) |

| Rear Taillights | OFF | ON |

Can DRLs be used as Headlights?

Absolutely not. In the hours of night, of dusk, or when foul weather doth prevail, to employ the DRLs as though it were the headlight is an act most perilous, and verily must never be done.

Such conduct begetteth grave hazards of safety, chiefly for two causes:

- Obscured Vision: As aforementioned, the brightness of the DRL sufficeth not to illumine the roadway. Neither pit nor steep incline, nor equipment nor wandering personage shall ye discern until the hour is already too late.

- Invisible Rearward: Forasmuch as the DRL kindleth not the tail lights, the hinder aspect of thy vehicle remaineth cloaked in near invisibility. Thus shall those who approach from behind fail to perceive thy presence, whereby the dire calamity of rearward collision may ensue.

When To Use DRLs and Headlights?

Using the correct light for the conditions is a mark of a professional operator. Here is a simple guide:

1. Use Daytime Running Lights (DRLs):

- During all daylight hours. Their automatic function means you rarely have to think about them, but it’s good to ensure they are working during your pre-start inspection.

2. Use Headlights (Low Beams):

- From dusk until dawn.

- During any adverse weather conditions (rain, fog, snow, heavy dust).

- Anytime visibility is poor.

- When working at night in an area with other machines or ground personnel.

3. Use Headlights (High Beams):

- Only when traveling at night on an empty haul road or worksite with no one in front of you.

- Immediately switch back to low beams as soon as you see another vehicle or person to avoid blinding them.

Investing in high-quality headlight bulbs is crucial for ensuring these systems perform reliably when you need them most.

Upgrade Your Right Parts Now!

To comprehend the disparity between the DRL and the headlight constitutes the foremost stride toward ensuring secure manipulation. Thereafter, it is the assurance that these contrivances remain forever in sound working condition. A bulb extinguished or a headlight part fractured is by no means a trifling occurrence, but rather a latent peril. Trustworthy and enduring parts may not only safeguard your fleet in safety, compliance, and efficiency, but also minimize the consumption of repair expenditure. As FridayParts hath been for many years a merchant in the realm of spare parts, ye are altogether spared from vexations of price and quality. Our fellowship shall exert utmost endeavor for the service of thy equipment’s repair. Delay not—peruse our wares forthwith.