When operators of heavy equipment discover strange performance situations — like difficulty in shifting, slow response during acceleration, or a continuous humming sound while moving — it often means that the transmission requires certain maintenance actions. In the machinery that travels off the highway, the transmission is not only responsible for controlling speed, but it also decides the level of productivity, the degree of safety, and the amount of cost spent per hour. In this guide, we will give an explanation about the function of the transmission, the ten warning signs that should not be ignored, and the methods for recovering the machine’s performance through dependable transmission parts.

What Is the Transmission & Why Is It Important?

In the domain of heavy machinery or off-road equipment, the transmission system takes upon itself the duty to convey the power of the engine toward the wheels or tracks in a manner of torque that is suitably arranged. No matter whether you operate an excavator, a loader, or a truck, this important part allows the machine to ascend steep slopes, to push materials of heavy nature, and to move with efficiency upon terrains that are rugged and uneven.

A healthy transmission ensures:

- Smooth gear changes under load

- Consistent torque delivery for safe operation

- Reduced engine strain and better fuel economy

Unlike light vehicles, off-road transmissions endure extreme torque loads and temperature variations daily. That’s why preventive maintenance — particularly regular fluid checks — is key to longevity. If you’re unsure how to test your fluid condition, it’s worth reading a simple maintenance guide like this step-by-step approach to checking transmission fluid to keep your components running smoothly.

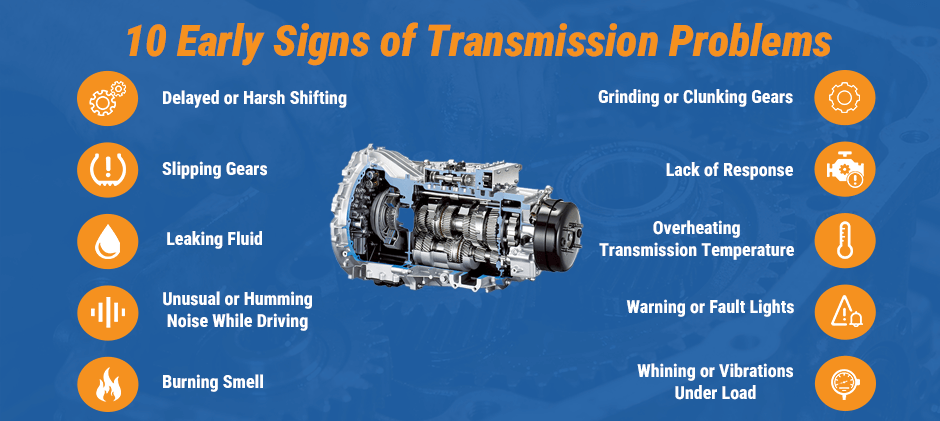

10 Early Signs of Transmission Problems

Off-road transmission issues rarely appear overnight. They often start with subtle signs. Let’s explore the ten most common ones and what they mean.

1. Delayed or Harsh Shifting

If your equipment hesitates before engaging gear or jerks during shifting, internal clutch packs or worn bearings could be at fault. These symptoms often accompany burned or low fluid — a clear indicator that service is overdue.

2. Slipping Gears

When gears disengage unexpectedly or the engine revs without movement, that’s a sign of internal wear or compromised torque converters. Operating under those conditions risks overheating and gear damage.

3. Leaking Fluid

Spotting red or amber fluid beneath the machine means your seals, gaskets, or transmission pump could be compromised. A small leak can quickly turn into total transmission failure without timely inspection.

4. Unusual or Humming Noise While Driving

That humming noise while driving — especially at steady speed — often traces back to worn bearings, damaged planetary gears, or misaligned shafts. This consistent vibration can also indicate that your differential or driveshaft U-joints are failing. Regular inspection and replacement using high-quality transmission parts such as bearings, shafts, and torque converters can prevent this from escalating into a full teardown repair.

5. Burning Smell

An overheating transmission fluid gives off a strong burning odor. This indicates excessive friction and possible contamination. Continued use in this condition can warp internal clutches and destroy seals.

6. Grinding or Clunking Gears

If you hear grinding or feel jolts during acceleration, you may be dealing with worn gears or improper lubrication. Left unresolved, this can strip gear teeth and require a complete gearbox replacement.

7. Lack of Response

When you switch from neutral or reverse to forward, and the equipment acts sluggishly or doesn’t move, fluid pressure might be too low, or the internal hydraulic valve could be stuck.

8. Overheating Transmission Temperature

For equipment working long hours in extreme weather, overheating is common. Overheating might stem from fluid degradation, blocked coolers, or a failing transmission pump. Temperature alarms should never be ignored; continued heat stress leads to irreversible clutch wear.

9. Warning or Fault Lights

Modern excavators, graders, and UTVs often display transmission warning indicators. When lights appear, it’s time to run diagnostics — continuing operation could lock your transmission into limp mode.

10. Whining or Vibrations Under Load

If the machine vibrates under heavy load, it could point to unbalanced shafts or failed torque converters. The sooner you isolate the cause, the less likely you’ll face secondary drivetrain damage.

Reasons Why Your Transmission May Be Failing

| Cause | Effect | Operator Tip |

|---|---|---|

| Low or contaminated fluid | Slipping, overheating | Perform routine fluid checks weekly. |

| Damaged torque converter | Poor torque transfer | Replace before heavy load operation. |

| Worn clutches or seals | Delayed engagement | Look for burnt odor or harsh shifts. |

| Overloading the machine | Excessive heat buildup | Follow rated capacity limits. |

| Neglected maintenance | Internal failure | Maintenance always costs less than repair. |

Many failures begin with simple neglect — infrequent inspections, contaminated oil, or ignoring the humming noise while driving that indicates early bearing wear. It’s also common for operators to overlook emission-related transmission interlocks or sensors. If your machine displays performance restrictions or emission warnings, consult this detailed resource on troubleshooting power and emission alerts; many “performance” issues are actually power management responses linked to transmission faults.

What Do I Do When I Have Transmission Problems?

When your off-road machinery starts exhibiting these signs, follow a disciplined checklist:

- Stop Operation Immediately – Avoid forcing engagement when gears slip.

- Inspect Fluid Levels – Follow manufacturer guidelines or refer to a reliable inspection tutorial to ensure proper levels.

- Scan Diagnostic Codes – Use onboard diagnostic tools to pinpoint faults.

- Replace Damaged Parts Promptly – Using OEM-quality replacements ensures reliability.

At FridayParts, we stock over 70,000 aftermarket components — from clutch kits and torque converters to full gearboxes. Our parts fit major brands like Komatsu, CAT, Hitachi, Kubota, Volvo, and more. High-quality, wear-resistant, and budget-friendly, these transmission parts help heavy-equipment owners fix their machines right the first time.

Maintenance Tip

Regularly scheduled fluid replacements and inspections — ideally every 500–800 hours, depending on the operating environment — drastically reduce the risk of failure. Pay special attention after working in muddy or waterlogged terrain, as moisture intrusion can quickly contaminate hydraulic systems.

Transmission Issues Frequently Asked Questions

1. Can I still operate my equipment with minor slipping?

You shouldn’t. Slipping increases wear each second of operation. Shut the machine down and inspect it immediately.

2. How often should transmission fluid be replaced?

It depends on workload, but high-torque off-road equipment should have fluid analyzed or replaced every 500 hours.

3. What happens if the transmission fails?

The equipment will lose motion transmission entirely, possibly causing cascading failures in hydraulic pumps or drive motors.

4. Can aftermarket parts really match OEM quality?

Absolutely, as long as they meet or exceed manufacturer specifications — which FridayParts ensures through rigorous quality testing.

Summary

To disregard problems of the transmission seldom brings favorable outcomes. The subtle humming sound during the vehicle’s movement, the shift that responds with tardiness, or the minor leakage of fluid — each of these phenomena serves as an initial indication of internal abrasion that may swiftly evolve into substantial periods of operational idleness. FridayParts provides aftermarket solutions designed with emphasis on durability under heavy-duty conditions, ensuring that your excavators, loaders, and trucks may continue their labor without imposing excessive burden upon your expenditures. You are invited to peruse our collection of transmission components so as to maintain the vigorous performance of your off-road machinery.