While heavy machinery owners and operators often focus on engine health, hydraulic pressure, and track tension, two crucial components for both performance and safety are commonly overlooked: the air filters. When someone mentions an “air filter,” they may be referring to two distinct parts with different functions: the engine air filter and the cabin air filter. Though both filter air, they protect entirely different systems.

This guide will explain what the cabin and engine air filters are, how they work, when to replace them, and more. By following these, you can ensure your equipment runs smoothly and your working environment remains comfortable.

Key Differences Overview

| Feature | Engine Air Filter | Cabin Air Filter |

| Primary Function | To protect the engine from contaminants. | To purify the air for the operator. |

| Location | Inside a large plastic housing in the engine bay. | Typically behind the glove box or under the dashboard. |

| Typical Interval | 250 – 500 service hours. | 500 – 1000 service hours, or annually. |

| Aftermarket Cost | $15 – $28 | $18 – $40 |

| OEM Cost | $25 – $50 | $30 – $75 |

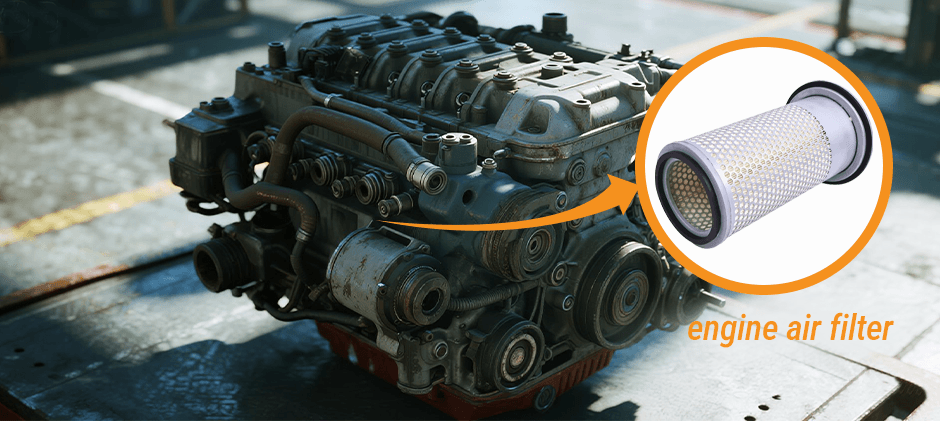

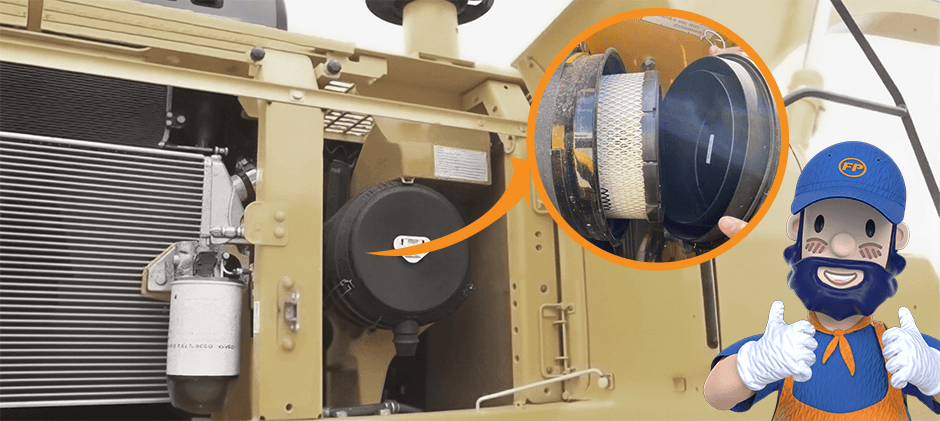

What Is an Engine Air Filter?

Think of the engine air filter as your engine’s lungs. As your engine runs, it pulls in a large volume of outside air for combustion. This air is directed through the engine’s intake system, where it must pass through the engine air filter. Made of pleated paper or cotton, the filter acts as a physical barrier, trapping abrasive particles like dust, sand, bugs, and other debris. This process ensures only clean, pure air mixes with fuel, allowing for efficient combustion and preventing contaminants from scoring cylinder walls, pistons, and other critical components.

What Is a Cabin Air Filter?

The cabin air filter is the guardian of the air you breathe inside your vehicle. It is a vital part of the Heating, Ventilation, and Air Conditioning (HVAC) system and does not impact engine performance. Its role is entirely focused on your health and comfort.

Before outside air enters the cabin through the heating or A/C vents, it passes through the cabin air filter. This filter is designed to trap a wide range of airborne particles that can affect your respiratory health and comfort. It effectively captures dust, pollen, soot, smog, and even unpleasant odors from exhaust gases. By cleaning the air you breathe, the cabin air filter creates a healthier and more pleasant environment inside your vehicle.

Engine vs Cabin Air Filters in Different Quantities

Most modern heavy machinery typically features at least two main air filters: one for the engine and another for the cabin. However, the exact number and type depend on the machine’s age, size, and specific setup. Knowing your equipment’s configuration is essential for proper maintenance.

- If your machine has an internal combustion engine, it must have an engine air filter.

- The Cabin Air Filter: Depends on Having an Enclosed Cab

- Equipment is Usually Equipped with a Cabin Air Filter: Typically larger, modern machines with enclosed, climate-controlled cabs for operator safety and comfort.

- Equipment Sometimes Featuring a Cabin Air Filter: Includes machines available with open cabs or enclosed cabs. The presence of a filter depends on the options selected at purchase.

Engine vs Cabin Air Filters Show Different Symptoms When Dirty

Neglecting a dirty filter can have serious consequences, which vary significantly between the engine and the cabin.

Effects of a Dirty Engine Air Filter

When an engine air filter becomes clogged, it effectively chokes the engine by restricting airflow. This causes several visible issues:

- Loss of Power: The engine feels sluggish and weak because it lacks enough air to maintain an optimal air-fuel mix.

- Increased Fuel Consumption: To offset the reduced airflow, the engine runs ‘rich,’ burning more fuel than necessary, which raises operating costs.

- Black Smoke from Exhaust: A common sign of a clogged filter, indicating unburnt fuel being expelled due to incomplete combustion.

- Severe Engine Damage: In the worst case, a torn or fully failed filter can permit dirt entry, acting like abrasive sandpaper on cylinder walls and pistons. This can lead to a costly engine rebuild.

Effects of a Dirty Cabin Air Filter

While a blocked cabin filter won’t harm the engine, it can negatively affect your health and comfort.

- Poor Air Quality & Health Risks: A contaminated filter can’t trap harmful particles, resulting in exposure to dust, pollen, and silica, which may cause allergies, respiratory issues, and long-term health problems.

- Musty or Unpleasant Odors: Over time, moisture and organic buildup can promote mold and bacteria growth on the filter, producing a persistent musty smell inside the machinery.

- Reduced HVAC Performance: If your fan runs at full speed but airflow remains weak, the filter may be clogged with debris, preventing proper air passage. How Often Should an Air Filter Be Replaced?

Engine Air Filter vs Cabin Air Filter Replacement Frequency

Refer to the manufacturer’s service manual for a baseline, usually based on operating hours.

- Engine Air Filter: Typically recommended every 250 to 500 service hours.

- Cabin Air Filter: It is usually recommended to change every 500 to 1000 service hours, or at least annually.

Nevertheless, these are general guidelines; actual needs depend on your working conditions and other factors.

1. The Operating Environment

An air filter‘s life isn’t measured in hours, but in the amount of dirt it has captured. This factor affects both the engine air filter and the cabin air filter directly, as both systems pull in contaminated outside air.

- An engine air filter needs to be replaced every 50-100 hours, not every 500 if a machine works in a rock quarry.

- The cabin air filter should be inspected as frequently and would likely require replacement every 100-200 hours.

This difference is because an engine pulls in a larger volume of air than a cabin’s HVAC system, causing its filter to clog more rapidly even under the same conditions.

2. Presence and Condition of a Pre-Cleaner

This factor is specific to the engine air filter. Many heavy-duty machines are equipped with a pre-cleaner system. This device uses cyclonic action to spin out larger particles before they reach the main filter.

A properly functioning pre-cleaner can remove up to 90% of coarse dust from the intake air. This can extend the life of the primary engine air filter by 3 to 5 times compared to a system without one. However, it’s critical to empty the pre-cleaner’s dust bowl daily. If it’s full, it’s not working.

3. Humidity and Moisture

High humidity is an often-overlooked factor that affects both filters, but in different ways.

- For the engine air filter, moisture can cause the paper pleats to swell and become restrictive, reducing airflow and engine performance even if the filter isn’t visibly dirty.

- For the cabin air filter, this is even more noticeable. A damp filter becomes a breeding ground for mold and mildew, leading to musty odors and poor air quality inside the cab.

4. Type of Debris

Not all dirt is created equal. The size and type of particles have a huge impact. Fine, powdery dust is far more damaging than larger particles. It clogs the microscopic pores deep within the filter media much faster. A filter can appear relatively clean on the surface but be internally clogged, reducing airflow by over 50%. While this affects both filters, the consequence is different.

- For the engine air filter, it leads to performance loss and damage

- The cabin air filter poses a direct risk to the operator’s health.

5. Engine Load and Air Demand

This factor is crucial for the engine air filter, but does not apply to the cabin filter. An engine running at high RPM under a heavy load is pulling in a massive volume of air. The same engine running slowly is consuming far less. Therefore, a machine that is consistently working hard will pull more dirt through its filter in the same number of service hours. The cabin air filter’s workload, in contrast, is determined by the HVAC fan speed and how often you run it, not by the engine’s performance.

In short, although the standard replacement hours are such, you’d better replace your air filters more often due to these factors.

When Replacing the Engine Air Filter or Cabin Air Filter?

Beyond the service manual’s mileage or time recommendations, your machinery will give you clear signals that a filter needs attention. Learning to recognize these signs for both the engine and cabin air filters can save you money and keep your machinery running smoothly.

- When the engine air filter gets clogged, it “chokes” the engine by restricting its air supply. Look for these symptoms: visual Inspection, decreased fuel economy, reduced acceleration, unusual engine sounds, and check engine light.

- Since this cabin air filter affects the air you breathe, the signs are often related to the interior environment and your HVAC system’s performance: weak airflow from vents, musty or unpleasant odor, increased fan noise, worsening allergies.

Engine Air Filter vs. Cabin Air Filter in Replacement Cost

The cost of replacing an air filter depends on whether you buy an expensive OEM part from a dealership or a more affordable aftermarket part, like those from FridayParts.

- For an engine air filter, an OEM part typically costs $25 to $50. In contrast, a high-quality aftermarket filter from FridayParts costs only $15 to $28, saving you around 40%.

- For a cabin air filter, an OEM part runs from $30 to $75, with the higher end being for charcoal-activated versions. An aftermarket filter from FridayParts costs just $18 to $40. This means you can often buy a premium, odor-absorbing charcoal aftermarket filter for less than a basic standard filter from the dealer.

If you have a mechanic perform the installation, expect to pay an additional $20 to $40 in labor for the engine filter and $30 to $60 for the cabin filter. The most economical option is to buy an aftermarket part and do the simple installation yourself.

Conclusion

After reading this guide, you should have a good understanding of the differences between the engine air filter and the cabin air filter: one protects your engine, while the other protects you. The next step is to put that knowledge into action. Routine maintenance is crucial for keeping your equipment running smoothly. When it’s time to find a replacement, FridayParts is your reliable supplier, providing high-performance aftermarket filters that offer OEM-level protection at a much lower price.