It’s critical to protect the engine for any off-road machinery owners, in which changing the oil & oil filter is minor, but easy to ignore. This guide will teach you deatiledly about their changing period, DIY changing guide, and where to find the reliable replacement parts. Follow this article, and you will get a healthy engine and well-running machinery.

What is the Engine Oil Filter?

Think of the engine oil filter as your machine’s kidney. Its job is simple but vital: to remove harmful contaminants from the engine oil.

As your engine works under heavy loads, the oil circulates to lubricate high-friction parts. In the process, it picks up microscopic metal shavings, soot from diesel combustion (a key concern for a diesel engine oil filter), and dirt. The oil pump forces this contaminated oil through the filter’s dense media, which traps these harmful particles. Clean, filtered oil then flows back to protect your engine’s critical components.

Location

On most heavy-duty diesel engines, the oil filter is a canister-style component screwed directly onto the engine block. Its exact position can vary, so always consult your machine’s service manual to locate it precisely.

When to Change Your Oil

This brings up a common question: do you have to change oil filter every oil change? The answer is simple and absolute: yes, every single time. There are no exceptions to this rule for high-value machinery.

However, that interval is based on average operating conditions. You must shorten this schedule if your machine works in harsh environments, which puts more stress on the engine and degrades oil faster. These conditions include:

- Extreme Environments: Constant operation in very dusty, dirty, or high-temperature sites.

- Heavy Loads: Consistent heavy lifting, digging, or pushing that keeps the engine under high strain.

- Excessive Idling: Long periods of idling followed by short bursts of intense work.

In short, changing the filter is not an optional add-on; it is a core, inseparable part of a proper engine oil and filter change service.

When to Change Your Oil Filter

The answer is simple: every single time you change the oil. There are no exceptions to this rule for high-value machinery.

Considering how much an oil filter change costs in the context of total machine ownership, skipping it is a risk that is never worth taking.

Why It’s Non-Negotiable:

- It Prevents Immediate Contamination: Your old filter is full of trapped sludge, metal shavings, and soot. Leaving it in place means the moment you pour in fresh, clean oil, it becomes contaminated. It’s like taking a shower only to put your dirty clothes back on—it defeats the purpose of the job.

- It Ensures Proper Oil Flow: As a filter clogs, it can trigger its internal bypass valve. This valve is a fail-safe designed to prevent oil starvation. Still, it does so by allowing completely unfiltered, dirty oil to circulate directly to your engine’s bearings, camshaft, and other critical components, causing accelerated wear.

In short, changing the filter is not an optional add-on; it is a core, inseparable part of a proper oil change service.

How to Change Your Engine Oil Filter: A Step-by-Step Guide

With the right approach and a focus on safety, performing an oil and filter change is a manageable task that puts you in control of your machine’s health. This guide is for owners with mechanical experience; if you have any doubts, hiring a professional technician is the safest choice.

1. Preparation and Safety

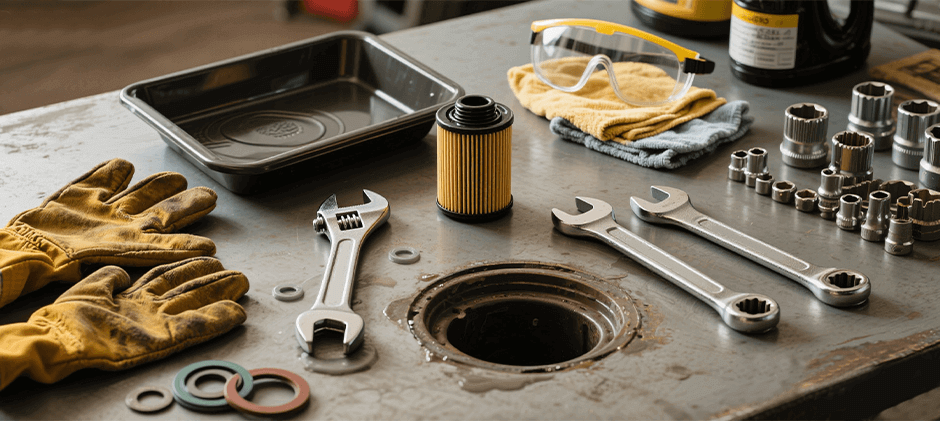

Before you touch a single tool, secure your safety and prepare the needed tools.

- Your machine’s service manual (for specs and capacities)

- The correct new oil filter from FridayParts

- Enough new engine oil that meets manufacturer specifications

- A large-capacity drain pan (heavy equipment holds a lot of oil)

- A correctly sized oil filter wrench. For heavy-duty canister filters, a heavy-duty strap wrench or a large socket-style cap wrench is essential. Never rely on hand strength alone for removal.

- A socket set and wrench for the oil drain plug

- A new sealing washer for the drain plug

- Clean rags and personal protective equipment (PPE), including safety glasses and oil-resistant gloves.

2. Draining the Old Oil

Position your large drain pan directly under the engine’s oil drain plug. Use the correct socket to loosen and remove the plug. The oil will drain quickly, so be prepared. Allow several minutes for the oil to drain completely. Once it has slowed to a drip, wipe the drain plug and the port clean, install the new sealing washer, and reinstall the drain plug, tightening it to the torque specified in your service manual.

3. Removing the Old Filter

Slide the drain pan directly underneath the old oil filter. Use your filter wrench to loosen the filter by turning it counter-clockwise. Once it’s loose, you can usually unscrew it the rest of the way by hand. The filter will be full of oil and heavier than it looks. As you remove it, carefully lower it into the drain pan.

Crucial Check: Look at the bottom of the old filter and at the engine block to ensure the old rubber gasket came off with the filter. If it sticks to the engine, you must remove it. Installing a new filter on top of an old gasket will cause a massive oil leak.

4. Installing the New FridayParts Filter

Take a clean rag and wipe the filter mounting surface on the engine block completely clean. Next, take your new FridayParts filter and dip a gloved finger into some clean engine oil, applying a thin film to the new rubber gasket. This lubricates the seal and prevents it from tearing upon installation.

For larger canister filters, it’s a good practice to pre-fill the filter about two-thirds full with new oil. This minimizes the time the engine runs without full oil pressure on startup.

Carefully screw the new filter on by hand until the gasket makes firm contact with the engine block. Then, tighten it an additional three-quarters of a turn by hand. Do not use the wrench to tighten the filter, as this can damage the seal or canister.

5. Refilling and Final Checks

Using a funnel, pour the correct type and amount of new oil into the engine, as specified in your service manual. Be careful not to overfill.

After refilling, start the engine. Watch the oil pressure light or gauge—it should return to normal within a few seconds. Let the engine run for a minute while you inspect the new filter and drain plug for any leaks.

Shut the engine off and wait 5-10 minutes for the oil to settle back into the pan. Pull the dipstick, wipe it clean, reinsert it fully, then pull it again to get a final, accurate oil level reading. Add more oil if needed.

6. Proper Disposal

Proper used engine oil filter recycling is not just good practice; it’s often legally required. Used oil and filters are hazardous waste. Effective engine oil filter recycling management involves taking them in a sealed container to a local auto parts store, a service shop, or a designated municipal recycling facility. Do not throw them in the regular trash.

How to Choose the Right Oil Filter

Not all filters are created equal. For hardworking machinery, a quality filter is a non-negotiable investment. Here are some tips for you to find the best engine oil filter:

- Use an Oil Filter Cross-Reference Tool: This is the most crucial step. Start with your machine’s OEM part number and use a reliable oil filter cross-reference database to find the correct aftermarket equivalent. For example, if you need a Wix replacement, using a Wix oil filter cross-reference chart ensures you get a filter with the exact same specifications for threads, gaskets, and performance.

- Correct Part Number: Always start with your machine’s OEM part number and use a trusted cross-reference tool to find the correct aftermarket equivalent. Fitment (thread size, gasket diameter) must be exact.

- Filter Media: Premium filters use synthetic blend or full synthetic media, which capture smaller particles and last longer than basic cellulose media. For an expensive engine, this is superior protection.

- Build Quality and Price: While a low oil filter price is attractive, it should not come at the expense of quality. Look for a sturdy canister, a reliable anti-drain-back valve (to keep oil in the filter when the engine is off), and a properly calibrated bypass valve.

Why Choosing FridayParts Is Wise

With over ten years of experience in this industry, FridayParts always offers the most reliable and compatible oil filters for major brands, such as CASE, Wix, Doosan, Hitachi, and more. Besides, our catalog is constantly expanding to make sure every customer can get what they need.

- OEM-Quality Performance: undergo rigorous testing and countless experiments.

- Superior Protection: We use high-efficiency filter media for capturing minimal contaminants in demanding off-road environments, extending your engine’s life.

- Low Price: Get the premium protection for your engine at a competitive price, helping you lower your operating costs without compromising quality.

- Maximized Uptime: With extensive stock, fast delivery, and global shipping, we ensure you get the right parts quickly, reducing downtime.

Protect your investment and ensure peak performance. Visit our one-stop online shop, explore the full oil filter catalog today!