Operating a fleet of forklifts in the absence of a daily inspection regimen is comparable to navigating through dense fog with impaired vision. Latent hazards may remain concealed until they abruptly arrest operational continuity — or, in a more grievous circumstance, give rise to personal injury. This guide proceeds to expound upon the necessity of daily inspection checklists, the regulatory requirements set forth by OSHA, and the proper execution of a comprehensive forklift inspection, encompassing meticulous pre-shift and in-operation examinations for both internal combustion (IC) forklifts and electrically driven units.

Why Your Forklift Should Use Daily Checklists?

A forklift might look rugged, but years of heavy lifting, hydraulic stress, and vibration cause wear faster than most operators realize. A simple pre-shift check identifies small issues before they turn into breakdowns.

Key Reasons for Daily Forklift Inspections

- Safety Compliance – OSHA mandates that forklifts be subjected to inspection on a daily basis before being placed into operation.

- Prevent Accidents – It allows for the prior discovery of deficiencies in braking systems, steering mechanisms, hydraulic functions, or tires before actual usage.

- Reduce Downtime – It ensures that minor imperfections are identified at an early stage, thereby preventing the degradation of operational performance.

- Extend Equipment Life – Forklifts that are maintained in proper condition tend to yield a superior return on investment and possess a prolonged service duration.

- Boost Operator Accountability – The implementation of daily inspection checklists encourages operators to assume responsibility for the condition of the vehicle.

If inspections reveal damaged components, replacing them with reliable aftermarket forklift parts—such as hydraulic seals, ignition switches, or fuel filters—ensures you’re not just compliant but operationally strong.

OSHA Forklift Maintenance Requirements

Under OSHA Standard 1910.178(q), forklift inspections must occur daily or at the start of each shift. These requirements exist to ensure that every lift truck used in the workplace is safe, properly maintained, and fully functional.

1. Daily Inspection Obligation

Before operating, each forklift must be reviewed for defects affecting safety—such as leaks, damage, or faulty safety devices.

2. Reporting and Repairs

If an issue is found, the forklift must be immediately removed from service until repaired. Continuing to use defective equipment can result in steep fines and increased risk of injury.

3. Recordkeeping

Although OSHA does not require written records, maintaining checklists proves compliance and supports internal monitoring.

4. Responsibilities

| Role | Responsibility |

|---|---|

| Employers | Provide safe equipment, schedule routine maintenance, and train operators. |

| Operators | Perform pre-shift inspections and report any defects. |

5. Frequent Violations

- Malfunctioning horns or lights

- Hydraulic leaks

- Worn or damaged tires

- Brake or steering issues

Proper documentation and daily checks protect not only compliance reputation but also daily performance.

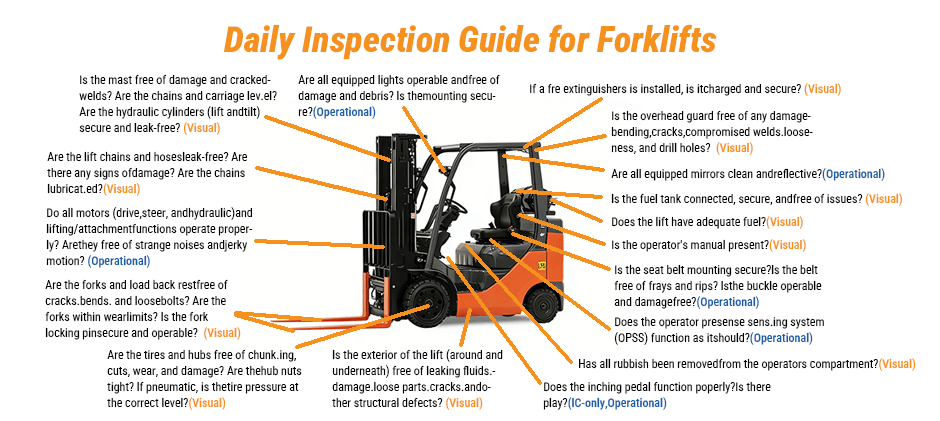

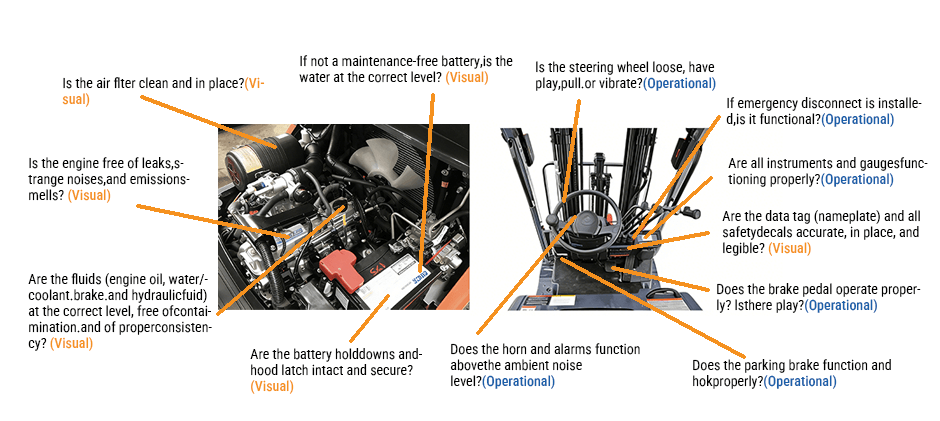

Forklift Inspection Complete Checklist

An effective forklift inspection has two stages: Pre-Shift (Visual) and Operational (Functional) checks. Both are essential to maintaining off-road machinery reliability.

Pre-Shift Forklift Inspection

Perform these visual checks before starting the engine:

| Category | What to Inspect | What to Look For |

|---|---|---|

| Tires & Wheels | Pressure, damage, debris | Deflated or uneven tires can cause instability. |

| Forks & Mast | Cracks, bends, and lubrication | Ensure mast rollers and lift chains are free of cracks or weld breaks. |

| Hydraulics | Hoses, fittings, and seals | Leaks or chafing lines indicate hydraulic wear. |

| Fluids | Oil, coolant, brake, and hydraulic levels | Maintain correct levels, check for contamination. |

| Battery or Fuel System | Connections and mounting | Secure cables, no visible corrosion or leaks. |

| Seat Belt & Safety Devices | Condition and lock function | Seat belts must fasten firmly without fraying. |

| Horn, Lights, Alarms | Visibility and sound | Must work clearly above background noise. |

| Overhead Guard | Cracks, loose bolts, and weld damage | Ensure the guard is secure and undamaged. |

| Fire Extinguisher | Present, charged, accessible | Should be checked monthly for readiness. |

| Operator Compartment | Cleanliness | Clear debris to prevent pedal obstruction. |

Operational Forklift Inspection

Start the forklift and confirm mechanical systems run smoothly:

- Steering: Smooth and responsive—no vibration or tight turning.

- Brakes: Both parking and service brakes hold properly.

- Hydraulic Controls: Tilt, lift, and lower smoothly without load instability.

- Instrumentation: Gauges and display lights respond accurately.

- Horn and Warning Alarms: Audible enough for warehouse or yard noise.

- Engine and Exhaust: No excessive smoke, leaks, or strange noise.

- Transmission: Forward, reverse, and neutral engage without delay.

- Operational Safety Devices: Ensure the Operator Presence System (OPSS) and emergency stop work properly.

If a component malfunctions, tag the forklift “Out of Service.” Replace faulty parts immediately using trusted forklift parts to prevent repeated failures.

Practical Visual Guide (Recommended for Print Use)

Your daily inspection sheet should include checked boxes for:

- Fluid levels

- Tire pressure

- Hydraulic lines

- Fork condition

- Warning devices

- Brakes and steering

- Fuel and battery checks

Include side visuals (like those showing labeled components for IC and electric forklifts) to speed up operator training and ensure consistent checks.

Forklift Safety Tips for Daily Inspections

A checklist yields its effectiveness solely when it is applied in a proper manner. The following practices serve to elevate the degree of accuracy and regulatory conformity:

- Affix identification tags to forklifts that are damaged and place them in isolation until the completion of repair; under no circumstance should lockout procedures be circumvented.

- Conduct operator training by means of sample inspection forms, with particular emphasis on the distinction between visual examination and functional verification.

- Document inspection outcomes either through digital systems or paper records, to establish accountability and facilitate audit review.

- Arrange periodic replacement of components in accordance with accumulated hours of operation.

- Maintain an adequate inventory of spare parts — filters, ignition coils, and seals are items of frequent demand in off-road applications.

Should the forklift be operated within environments characterized by mud or dust, it is advisable to perform cleaning weekly. The accumulation of dirt around the radiator or mast gearing may induce engine overheating and bring about a decline in operational efficiency.

FAQs

1. How often are forklift inspections required?

Every workday or before each shift, if multiple operators use the same forklift.

2. Can operators perform their own inspections?

Yes. OSHA expects operators to complete and sign their daily inspection checklist before starting the vehicle.

3. What if I find a defect during inspection?

Stop the operation immediately. Only a qualified technician should repair or approve continued use.

4. How long does the inspection take?

Most thorough checks take 5–10 minutes per forklift.

5. Are electric and diesel forklifts inspected differently?

They share most points, but electric models require extra attention to battery electrolyte levels, and IC forklifts need more frequent oil and exhaust checks.

Wrapping It Up

To operate an off-road fleet in the absence of a methodical inspection arrangement places safety, operational continuity, and regulatory conformity in a state of jeopardy. By adhering to a comprehensive forklift maintenance checklist, the equipment may retain its reliability, the operators remain under adequate protection, and OSHA requirements can be fulfilled with consistency. When abrasion or malfunction is detected, one should depend upon trustworthy aftermarket forklift parts. FridayParts furnishes replacements of elevated quality at prices of competitive nature, applicable to major brands such as Toyota, Komatsu, Mitsubishi, Jungheinrich, and TCM.