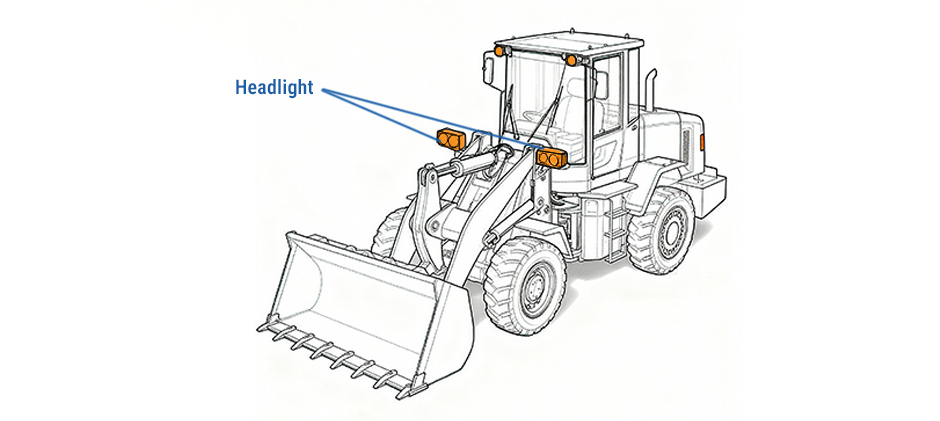

A headlight of full function is not a thing of extravagance, but rather an instrument of utmost necessity for safety and productivity. Whether it be that you commence your labor before the rising of the sun, or conclude it after the setting thereof, in conditions where sight is meager, the headlight is of paramount importance both for the seeing of your own working ground and for being beheld by others. The extinguishing of the headlight bulb brings not merely inconvenience, but also a peril to safety, which may cause interruption of your undertaking. This guide shall discuss the practical expenses in the year 2025 of replacing the headlight bulb of heavy machinery, to examine the several kinds of bulbs, the cost of human toil, and the manner in which one may economize whilst yet ensuring illumination of the workplace in safety.

Headlight Replacement Quick Facts

- Aftermarket Bulb Cost: The game has changed. You can now get a high-quality, heavy-duty aftermarket headlight bulb for $10 to $40 at FridayParts.The market price of headlight parts is about $10 to $200.

- Professional Replacement Cost: A professional replacement, including parts and labor, typically ranges from $70 to $450. The final cost depends heavily on the accessibility of the headlight housing on your specific machine.

- Labor Costs: Heavy equipment mechanic labor rates range from $120 to $200 per hour. A simple replacement might take 15 minutes, while a difficult one could take over an hour.

- Replace in Pairs: It is always recommended to replace both headlight bulbs at the same time to ensure even brightness and prevent the other old bulb from failing shortly after.

The Different Headlight Types

The type of bulb in your machine is the single biggest factor determining performance and long-term value. Here are the common types you’ll find in off-road equipment.

1. Halogen Bulbs

Halogen bulbs have been for a long time the standard in industry, especially for vehicles of older versions or the basic type. Its working principle is, by heating the tungsten wire, which is staying in one halogen gas capsule, then producing a warm and pale yellow light.

- Pro: The cost in the beginning is extremely low.

- Cons: Life is shortest, efficiency of energy is lowest, and the fragile filament is very easily damaged because of the continuous vibration from heavy machinery. Among the three main bulb types, its light is the darkest.

2. LED (Light Emitting Diode) Bulb

LED is now becoming a new standard for illumination in many kinds of devices. They shine by a semiconductor giving out light. LED is one kind of solid-state technology, meaning that inside, there is no fragile filament.

- Pro: Extra-long using life (often more than 30,000 hours), excellent durability and anti-shock ability, can save energy, and can send out very bright and clear white light, making visibility much improved.

- Cons: Traditionally, front costs more, but nowadays, good quality aftermarket products are not like this anymore.

3. HID (High Intensity Discharge) / Xenon Bulb

An HID bulb shines by creating one arc between two electrodes, igniting xenon gas inside the bulb. Before LEDs became popular, they were a very popular high-end bulb.

- Pro: Brighter than a halogen bulb, and it also lasts longer.

- Cons: More expensive than halogen, needs a ballast to work (another possible failure point), and also needs a short warming-up time before it can reach maximum brightness. Their performance and durability today are already much behind modern LED lights.

How Much Does A Headlight Bulb Cost?

This one is a core question, and the answer depends on whether you yourself do the action or you hire a professional person. Let us analyze the cost in these two kinds of situations, especially for the heavy-duty equipment. If you own some basic tools, and you can carry out the simple maintenance, then replacing the bulb by your own hand is the most economical and also the most beneficial way. The only cost for you is just the part itself.

| Bulb Type | Average Cost (Pair) | Lifespan (Operating Hours) | Light & Durability |

|---|---|---|---|

| Halogen | $10 – $50 | ~1,000 hours | Yellowish light, poor vibration resistance. |

| HID/Xenon | $30 – $150 | ~5,000 hours | Bright blue-white light, moderate durability. |

| LED | $20 – $120+ | 30,000+ hours | Bright white light, excellent vibration resistance. |

As the table clearly shows, while halogen bulbs are cheap to buy, their short lifespan in a harsh worksite environment makes them the most expensive option in the long run. An investment in LED bulbs can pay for itself many times over through sheer longevity and by eliminating the downtime needed for frequent replacements.

How to Choose the Right Headlight Bulb?

Selecting the right replacement headlight bulb involves more than just finding one that fits.

- Confirm Compatibility: First, you need the correct bulb number (e.g., H3, H4, 9005). You can find this in your machine’s operator’s manual or by removing the old bulb. Crucially, you must also confirm the voltage. Most heavy equipment uses a 24V system, but some smaller machines might use 12V. Installing a 12V bulb in a 24V system will destroy it instantly.

- Choose Your Technology: Given the new price parity, the choice is clear. For any working machine, the durability, lifespan, and superior brightness of an LED are the logical choice over a fragile halogen.

- Consider Your Work Environment: If you operate in extremely dusty, wet, or high-vibration environments, a heavy-duty, fully sealed LED work light or headlight is your best option. These units are designed to withstand the abuse of a worksite far better than any standard automotive-grade light.

- Buy from a Reputable Aftermarket Source: This is the key. To get the benefits of LED technology at this low price point, you need to buy from a supplier that specializes in heavy equipment parts. They will have a vast inventory of durable, high-quality headlight bulbs designed for the demands of your industry, without the dealer markup.

Tips to Save on Replacement Cost

- Purchasing Aftermarket Parts: This is the primary selection for saving money. It can allow you to upgrade to more advanced LED technology at the price of a standard halogen bulb, combining low cost and high performance, making you obtain the effect of having both sides.

- Doing by Oneself: This can save the cost of manpower. For most machines, replacing the headlight is a simple task that you can finish by using basic tools.

- Replacing in Pair: Must replace both bulbs at the same time. If one bulb is broken, the other bulb is also nearly finished its life. In this way, it can ensure that you obtain uniform and reliable illumination, and also no need to do the same work again after several weeks.

When to Replace Your Headlight Bulb?

Do not wait till the bulb has already perished completely, then only go for repair. The following omens manifest that your headlight bulb is soon going to expire:

- Flickering or Dimming: The light is flickering or obviously weaker than in the past; this is a clear sign that the bulb or the connection has a defect.

- Lens Turbid or Yellowing: The plastic shell itself, with the passage of time, will age, becoming turbid or yellow. This will greatly restrict the light emission, meaning the whole component ought to be replaced.

- Visible Damage: Flying debris will cause the shell to crack, moisture and dust will intrude inside, thereby rapidly damaging the bulb and reflector.

- Frequent Burnout: If every several months you must replace the same halogen bulb, this is showing your machine vibrates excessively. At this moment, it is indeed the best occasion to replace it with a durable LED bulb at an affordable price.

Light Up Your Worksite for Less

To elect the most suitable headlight bulb for your heavy-duty equipment, it is necessary to maintain a delicate equilibrium among preliminary expenditure, long-term valuation, and the matter of safety. While the inexpensive halogen bulb appears as a swift remedy at the surface level, the act of investing in an elevated-grade LED bulb upgrade manifests itself as the most sagacious financial determination for any machine presently engaged in labor. Such a choice may diminish the occurrence of downtime, augment the dimension of safety, and eliminate the repetitive expense brought forth by frequent replacement. By means of procuring components from a reliable aftermarket supplier, namely FridayParts, one may acquire the required durable and high-performing illumination within a budget-concordant price range, thereby guaranteeing the worksite to remain in a state both safe and efficient.