Many a construction site, farm, and mine oftentimes must confront the necessity of operating machinery ere the break of dawn or amidst the nocturnal hours. Beneath such meager illumination, the headlamps of the machine constitute verily the paramount safeguard. Yet, the mere act of igniting them doth not suffice. To wield the improper beam at the improper juncture is fraught with peril no less grave than neglecting illumination altogether, thereby imperiling both operator, ground attendants, and precious apparatus. To apprehend the fundamental divergence between high beam and low beam serves not solely the observance of regulation; of greater import it is, to amplify visibility to its utmost and assure the sanctity of safety. This present compendium shall expound in detail the several functions of each beam, and bequeath unto the reader perspicuous and pragmatic ordinances for their application within the off-road dominion.

What are High Beam & Low Beam?

Although the high beam and the low beam are both installed inside the same headlamp component, they are actually two kinds of tools utterly not the same, being designed for completely different purposes. One should not merely imagine them as “brighter” and “darker,” but rather one ought to regard them as the spotlight and the floodlight.

What is High Beam?

High beams, sometimes called “main beams” or “full beams,” are designed for maximum forward illumination when you are alone in a dark, open area.

- Their Purpose is Distance: The paramount function of the high beam lies in projecting the rays of illumination unto the utmost remoteness of roadway or construction ground. By such extension, one may behold from afar the lurking perils—be they depressions upon the transport path, scattered gravels, wandering beasts, or the very brink of a mining pit—thus being endowed with augmented moments to contrive a response.

- They have a Focused Beam: High beams produce a bright, intense, and centrally focused pattern. The light is aimed nearly straight ahead, parallel to the ground, to achieve maximum range.

- They are a “Spotlight”: Think of a high beam as a powerful spotlight. It’s excellent for inspecting a high wall in a quarry from a distance or checking the far end of a long field, but it’s far too intense and direct for use around other people.

What is Low Beam?

Low beams, also known as “dipped beams,” are your standard, everyday headlights for working in proximity to others or in conditions that require careful, close-range visibility.

- Their Purpose is Safety and Proximity: Low beams are designed to illuminate the area directly in front of and to the sides of your machine without blinding other operators or ground crew.

- They have a Controlled Beam Pattern: The most important feature of a low beam is its sharp “cutoff” line. The light is physically aimed downward and has a distinct pattern that is flat on top. This prevents light from shining up into the eyes of an approaching operator.

- They are a “Floodlight”: A low beam provides a wide spread of light to illuminate the immediate work area. This is perfect for maneuvering in a crowded equipment yard, loading trucks, or when ground personnel are present, as it lights up the ground without creating dangerous glare.

What is the Difference Between High & Low Beams?

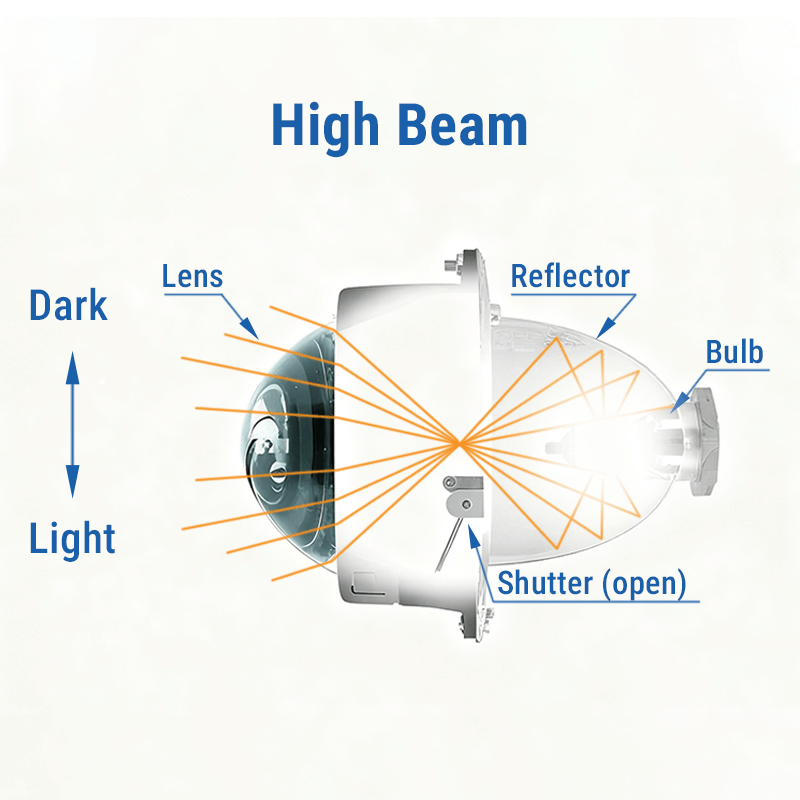

The essential distinction between the high beam and the low beam does not solely reside in the mere brightness, but rather in the peculiar configuration and orientation of the luminous stream. Though both emanate from the selfsame bulb within the headlamp, it is the assemblage of the headlamp itself that performs the shaping of the ray, thus begetting two utterly divergent functions.

In the most elementary parlance:

- High Beam = A Spotlight. It projecteth a slender yet vehement shaft of brilliance, illuminating objects afar.

- Low Beam = A Floodlight. It casteth forth a broad and well-governed effulgence, rendering visible with safety the domain anterior and lateral to the machine.

1. Beam Angle & Direction

This is the most critical difference.

- High Beams are aimed almost straight ahead, parallel to the ground. This is what gives them their incredible range.

- Low Beams are physically angled downward. They have a sharp, flat “cutoff” line at the top of the light pattern, which is designed specifically to prevent light from shining up into the eyes of approaching operators.

2. Primary Purpose

Each beam is a tool for a specific situation.

- High Beams are for maximum long-distance visibility when you are operating alone in a dark, open area.

- Low Beams are for safe, close-range visibility when working near other people or machines, or in poor weather.

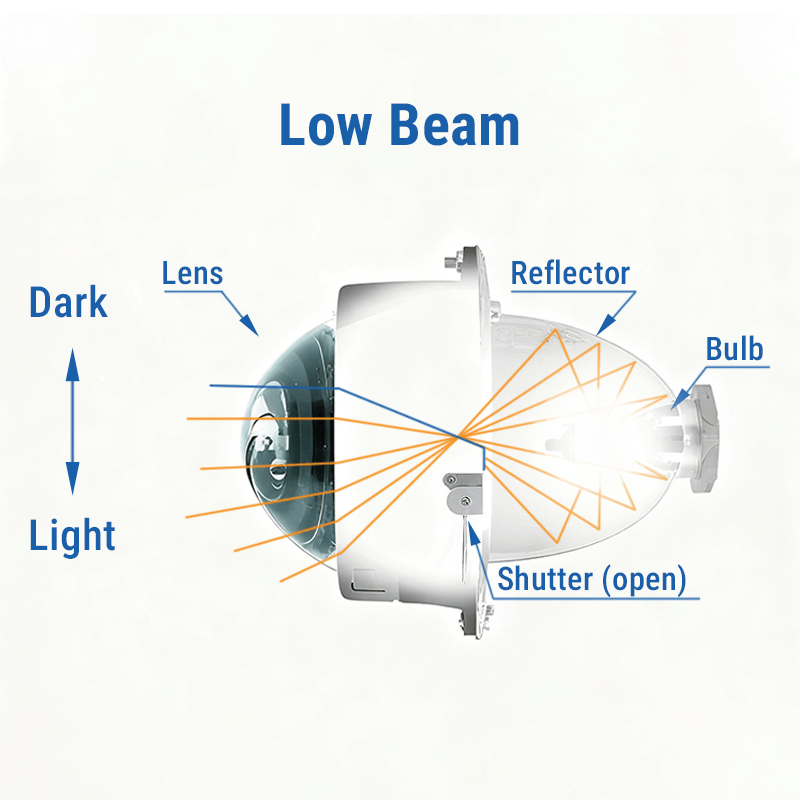

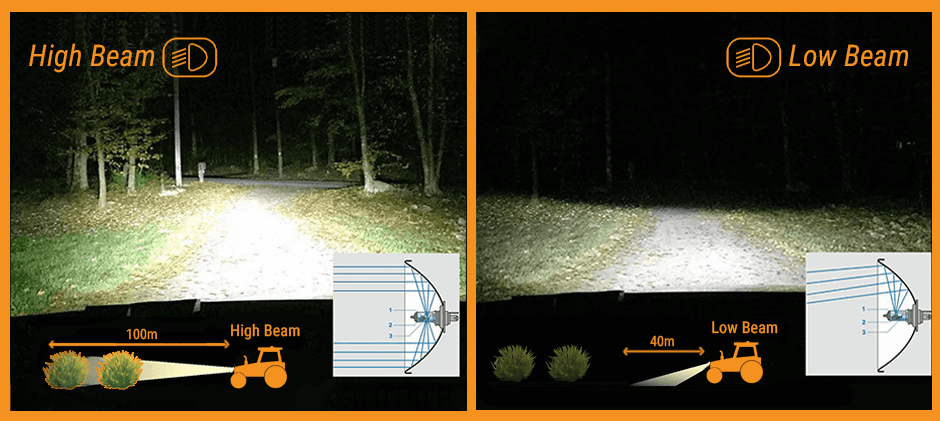

3. Effective Range & Coverage

They illuminate completely different zones.

- High Beams can illuminate hazards from 350 to 500+ feet away, but the beam is relatively narrow.

- Low Beams light up a much wider area, but only for about 150 to 200 feet. This wide spread is crucial for seeing the edges of a work area or personnel standing to the side.

4. Effect on Others

This is the most important safety consideration.

- High Beams cause severe, dangerous glare that can temporarily blind anyone in their path.

- Low Beams are designed to minimize glare, allowing other operators and ground personnel to work around you safely.

High vs Low Beam Comparison

| Feature | High Beam | Low Beam |

|---|---|---|

| Beam Angle | Aimed straight ahead, parallel to the ground. | Angled downward with a sharp upper cutoff line. |

| Primary Purpose | Maximum long-distance visibility in open areas. | Safe, close-range illumination without blinding others. |

| Illumination Range | 350-500+ feet (100-150+ meters) | 150-200 feet (45-60 meters) |

| Intensity & Pattern | Highly intense, focused central hotspot. | Less intense, wider, and evenly distributed pattern. |

| Best Use Case | Traveling alone on dark rural roads, inspecting distant areas. | Working near other machines/personnel; dusty/foggy conditions. |

| Effect on Others | Causes severe, dangerous glare; temporarily blinds them. | Minimizes glare, allowing others to see and work safely. |

Understanding these differences is key to using your machine’s entire light system correctly and safely. Now, let’s look at the specific on-site situations where you should use each one.

When to Use High Beams & Low Beams?

Knowing the technical differences is one thing; applying them on a dynamic job site is another. Here are the clear, practical rules for your off-road equipment.

You MUST Use High Beams When:

- Traveling on Unlit Haul Roads or Farm Lanes ALONE: When thou art solitary proceeding upon the protracted and obscure thoroughfare, the high beams are of utmost indispensability for discerning in advance the hollows, the washed-away debris, or the creatures.

- Working in an Isolated Section of a Large Site: Should one be situated in the remote extremities of a mining field, quarry, or vast construction ground, with no other personnel or machinery within the range of vision, the high beam must be employed to sufficiently irradiate one’s sphere of labor.

- You Need to See Far Away: the high beam may be utilized as an instrument to swiftly scrutinize the firmness of towering walls, to examine the fencing line upon the property’s border, or to identify a distant marker.

You MUST Use Low Beams When:

- Another Machine is Approaching: As a rule, you should switch to low beams when an oncoming vehicle is within 500 feet. This prevents you from blinding the other operator.

- You are Following Another Machine: If you are following another truck or piece of equipment, your high beams will reflect off their mirrors and blind the operator in front of you. Switch to low beams when you are within 200-300 feet.

- Ground Personnel are in the Area: This is a non-negotiable safety rule. High beams can easily blind a spotter or worker on the ground, causing them to become disoriented and potentially step into a dangerous area.

- In Dusty, Foggy, or Snowy Conditions: This is a critical point that many operators get wrong. High beams are worse in these conditions. The intense light reflects off the particles (dust, water droplets, snowflakes) in the air, creating a “white wall” of glare that severely reduces your visibility. Low beams, aimed downward, cut underneath the worst of the airborne particles and provide much better vision.

- Maneuvering in Congested Areas: When parking in the yard, approaching the fuel bay, or working in a tight loading zone, low beams provide the best close-range visibility without disrupting other operations.

For tasks requiring intense, specific area lighting without affecting others, a dedicated LED work light is often a better solution than relying on your main travel headlights.

Practical Tips for Maximizing Light Effectiveness

Beyond knowing when to switch between high and low beams, maintaining your lighting system properly is equally crucial to ensure optimal performance.

- Regular Cleaning & Inspection: Dust, mud, and oil film can significantly diminish light output. Clean the headlamp lenses weekly and check for cracks or fogging that may diffuse the beam.

- Accurate Headlamp Alignment: Even the best light is ineffective if misaligned. Periodically test your beam aim—especially after rough operation or part replacement—to ensure proper projection distance and cutoff line.

- Choosing the Right Bulb: Consider LED or halogen bulbs designed for heavy-duty off-road use. LEDs provide stable brightness, longer lifespan, and lower energy consumption—ideal for long night shifts.

- Use Auxiliary Lighting: In complex working areas, combine your standard beams with LED work lights or flood lamps to cover blind spots and expand illumination without disturbing others’ visibility.

- Nighttime Safety Cooperation: Coordinate lighting usage among drivers and spotters through communication devices. A well-timed switch from high to low beam can prevent accidents and enhance teamwork efficiency.

Proper lighting management isn’t just a technical practice—it’s part of professional worksite safety culture. Operators who understand and apply beam control effectively not only protect themselves but also significantly improve overall productivity.

Upgrade Your Visibility, Upgrade Your Safety

To comprehend and to employ the high beam and the low beam is a fundamental skill belonging to any professional operator. This simple habit is exerting enormous influence upon the entirety of the safety and efficiency of the operation. Under no means should your safety be put into jeopardy because of such. The aftermarket accessories of high quality are providing an economical and efficient method, which can ensure that your illuminating system remains in perfect working condition. FridayParts possesses a great quantity of spare parts stock compatible with numerous brands of heavy-duty equipment, by which you may obtain, at an affordable price, the high-quality products you are in need of, thereby ensuring your machine is both safe and efficient.