The combine harvester is a marvel of agricultural engineering; they akin to an independent mobile factory, can swiftly turn the crops in the field into clean grains. For farmers and equipment operators, this machine is the device of highest utilization frequency during the autumn harvest season. Yet, beneath the exterior of the harvester, there is concealed a complex, synchronized system composed of harvester parts, which they coordinate in perfect harmony. Comprehending this intricate process may assist you in, when necessary, maximizing crop harvesting efficiency and troubleshooting equipment failures. This guide will dissect the entire harvesting procedure, from the cutter bar to the grain tank, letting you clearly understand the specific operation inside the combine harvester.

What is a Combine Harvester?

The combine harvester, in essence, constitutes a multifunctional machine, conceived for the purpose of effectuating the harvesting of diverse cereal crops with heightened efficiency. The denomination “combine harvester” derives from its operational capacity, as it amalgamates three discrete harvesting procedures—reaping, threshing, and winnowing—into a singular continuous process. Before the advent of the combine harvester, these undertakings were labor-intensive, necessitating multiple machines alongside substantial human labor. In contemporary practice, a solitary operator is capable of harvesting extensive tracts of land within an exceedingly brief temporal span. It serves as an indispensable apparatus in modern large-scale cereal cultivation, ensuring that crops such as wheat, maize, soybeans, oats, and barley are reaped swiftly and efficiently, thereby minimizing crop loss and optimizing yield to the utmost degree.

Main Components of a Combine Harvester

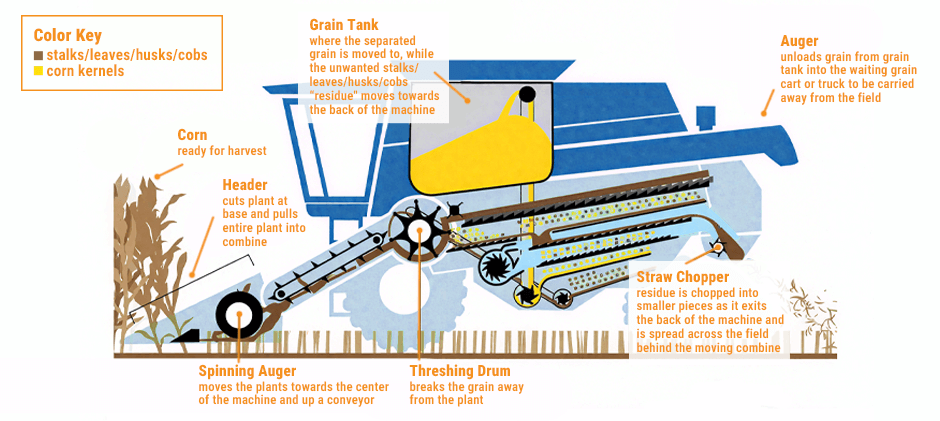

To comprehend the working principle of a combine harvester, firstly, we must acquaint ourselves with its key components. Although designs may differ, almost all combine harvesters share these fundamental parts in their construction. By observing the combine harvester parts diagram, one can visually apprehend their functions, which is conducive to clarifying their roles:

Cutting and Intake Components

- Header: This is the broad attachment located at the foremost part of the combine harvester. It bears the responsibility to reap the crops and collect them into the machine. Different crops use different cutting platforms (for instance, the grain platform and the corn platform).

- Reel / Rotating Auger: A large rotating mechanism upon the cutting platform. On the grain platform, the reel with teeth or bars presses crops downward toward the cutter bar. In many cutting platforms, the rotating auger subsequently conveys the cut crops to the center.

- Cutter Bar (or Sickle): A long bar with reciprocating blades, extending along the bottom of the cutting platform, cutting crop stalks from the root.

- Feederhouse (or Feeder Conveyor): An enclosed conveyor, which transmits the harvested crops from the cutting platform to the body of the combine harvester for processing.

Threshing and Processing Components

- Threshing Drum / Cylinder: The core of the combine harvester. It is a heavy, fast-rotating drum, equipped with metal bars (rasps), employed to strike crops, causing grains to detach from stems, stalks, and heads.

- Concave: A curved, grille-like metal component, located under the threshing drum. Crops struck upon the concave have grains separated and dropped through the openings of the concave.

- Straw Walkers / Separator: After threshing, straw and other large materials (residues) pass through the straw walker — a long swinging frame, which shakes off any remaining loose grains. In rotary combine harvesters, this function is accomplished by the separation rotor using centrifugal force.

- Cleaning System (Cleaning Sieve): This system is positioned beneath the straw walker. It combines a vibrating sieve and a powerful fan, separating clean grains from husks and other small impurities.

- Grain Tank: A large grain storage bin atop the combine harvester, used to collect clean grains.

- Unloading Auger: A long powered tube, with an internal spiral, used to transfer clean grains from the grain tank to the grain cart or truck.

- Straw Chopper: An optional but common attachment at the rear of the machine, employed to chop the remaining residues into small pieces, then scatter them back to the field.

How Does a Combine Harvester Work?

Now, let’s put the harvester parts into motion and follow the journey of a crop from the field to the grain tank. This multi-stage process, as illustrated in many diagrams, is a masterpiece of mechanical synchronization.

Stage 1: Cutting and Gathering

The process begins at the Header. As the combine moves through the field, the header engages the crop. For corn, specialized “row units” pull the entire plant in. For wheat or soybeans, a rotating reel pushes the standing crop towards the cutter bar. The sharp, reciprocating blades of the cutter bar slice through the stalks just above the ground. Once cut, a spinning auger or a draper belt immediately sweeps the cut material—which now consists of grain, stalks, leaves, and cobs—towards the center of the header and into the feederhouse. The header components’ speed carefully matches the combine’s ground speed to ensure a smooth, even feed without losing valuable grain.

Stage 2: Feeding into the Thresher

The Feederhouse acts as an elevator. A chain-and-slat conveyor moves the cut crop upward and back into the machine for threshing. A consistent, even flow at this stage is critical for efficient threshing and preventing blockages.

Stage 3: Threshing – Breaking the Grain Away

This is where the real separation begins. The material from the feederhouse enters the gap between the rapidly spinning Threshing Drum and the stationary Concave. The rasp bars on the drum aggressively beat and rub the crop against the concave. This violent action is what breaks the grain away from the plant, shattering corn cobs and wheat heads to release the valuable kernels.

The vast majority of the grain (around 90%) is separated at this stage. The heavy kernels are small enough to fall through the grates in the concave and onto the cleaning system below.

Stage 4: Separation – Saving the Last Kernels

The material that was too large to fall through the concave—mostly stalks, leaves, and cobs, collectively known as “residue”—is not discarded yet. It is discharged from the back of the threshing drum onto the Straw Walkers. These are long, perforated racks that oscillate with a distinct up-and-back motion. This shaking action tumbles the mat of residue, allowing any remaining trapped kernels to fall through the perforations and join the rest of the grain on its way to the cleaning shoe. In a rotary combine, this process is handled by one or two large rotors that use centrifugal force to sling the heavier grain away from the lighter residue.

Stage 5: Cleaning – The Final Polish

The mixture that has fallen through the concave and straw walkers is now on the Cleaning Shoe. It consists of grain, but also contains a lot of lighter chaff, small pieces of stalk, and other debris. The cleaning process has two main parts:

- Sieves (or Screens): The material falls onto a set of two or more oscillating sieves (the chaffer and the sieve). These screens have adjustable openings that allow the small, heavy grain to fall through but hold back larger pieces of debris.

- Fan: A large fan blows a powerful, precisely directed stream of air up through the sieves. The air blast removes light chaff and dust without displacing the heavier grain.

What emerges at the bottom of the cleaning shoe is clean, high-quality grain.

Stage 6: Storage, Unloading, and Residue Management

A series of augers or elevators collect the clean grain (corn kernels, in the diagram) in a trough and carry it up to the Grain Tank. When the tank is full or when a grain cart is available, the operator engages the Unloading Auger. This long arm swings out from the side of the combine, and its internal screw rapidly transfers the grain from the tank into the waiting cart or truck for transport.

Meanwhile, the straw chopper handles all leftover stalks, leaves, husks, and cobs from the machine’s rear. This unit uses a set of flailing blades to chop the residue into smaller pieces, which are then spread evenly across the field to return nutrients to the soil.

Types of Combine Harvesters

While they all perform the same core function, combines come in a few different configurations.

| Type | Description | Best For |

|---|---|---|

| Self-Propelled Combine | The most common type. The engine, driving controls, and harvesting mechanism are all integrated into one large machine. | Large-scale commercial farming, versatile for all crop types with interchangeable headers. |

| Pull-Type (or Tractor-Pulled) Combine | A smaller harvesting unit attaches to a tractor and uses the tractor’s PTO (Power Take-Off) shaft for power. | Smaller farms, specialty crops, or operations with a lower budget. |

| Conventional Combine | Uses a transverse threshing cylinder and long straw walkers for separation. | Very effective in dry, brittle crop conditions. A proven and reliable technology. |

| Rotary Combine | Uses one or more large, longitudinal rotors for both threshing and separation. | Higher capacity, gentler on grain, and performs better in tough, damp crop conditions. |

Keep Your Harvest Running Smoothly

By comprehending the functional roles of each component of the combine harvester as well as the movement patterns of crops within the machinery, one is enabled to make wiser adjustments during equipment inspection and maintenance, and to diagnose issues with greater rapidity. Mastery of this knowledge allows for more efficient operation of the harvester and, most importantly, the attainment of elevated profits in the harvest season. When parts undergo wear, consideration may be given to selecting reliable and cost-effective components from FridayParts’ abundant inventory, ensuring that your machine is perpetually prepared to confront the next challenge, thereby permitting tranquil harvesting of crops during the busy autumn season.