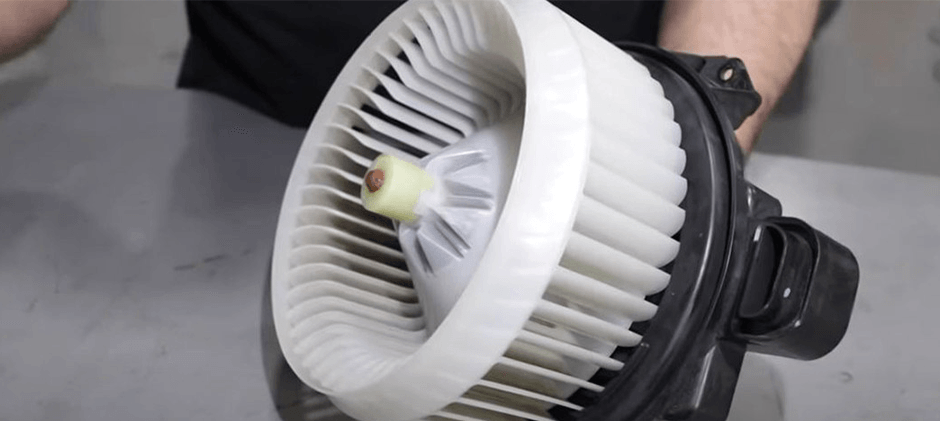

The blower motor powers the fan that circulates heated or cooled air through vents, ensuring comfort in extreme weather and clear visibility by defrosting windows. If you want to know more, you can read: What Is a Blower Motor?

When it malfunctions, an operator’s day can become difficult or even unsafe. Therefore, prompt replacement is essential when failure occurs. But what is the cost of repair? In 2025, replacing a blower motor on heavy machinery can cost between roughly $400 and over $2,500. This broad range depends on factors such as labor rates, the choice of part, the machine’s make and model, and the motor’s technical specifications. This guide outlines all aspects of the replacement cost, helping you make informed decisions, reduce downtime, and get your equipment operational again.

What Constitutes the Blower Motor Replacement Cost?

The total blower motor replacement cost is primarily divided into two categories: labor and parts. For heavy machinery, both can vary more than they would for a standard passenger vehicle or a home HVAC unit.

Labor Cost

Replacing a blower motor on heavy equipment is not always a simple task. Depending on the machine, the motor could be located deep within the dashboard or in a tightly packed engine compartment. The complexity of the job directly impacts the labor cost.

- Hourly Rates: A qualified heavy equipment technician typically charges between $100 and $200 per hour. This rate reflects their specialized knowledge and the complex nature of machinery, electronics, and mechanics.

- Time Required: A straightforward replacement might take 1.5 to 2 hours. However, if the technician needs to dismantle a significant portion of the cab or dashboard to access the motor, the job could easily extend to 4 hours or more.

This puts the estimated labor cost in the range of $150 to $800, before any diagnostic fees are added.

Parts Cost

The motor itself is the other major part of the equation. Here, you have a critical choice to make between OEM and aftermarket parts, which will be the single biggest influence on your material costs.

OEM Parts

OEM parts are made by the same company that manufactured your machine.

- Pros: They guarantee a perfect fit and are often perceived as the “safest” option.

- Cons: They come with a premium price tag. An OEM blower motor can cost anywhere from $500 to $ 1,500 or more, depending on the machine.

Aftermarket Parts

Aftermarket parts are produced by third-party companies. They are designed to function identically to OEM parts and are often the smartest choice for out-of-warranty repairs.

- Pros: The primary advantage is cost. A high-quality aftermarket blower motor can be 40-70% cheaper than its OEM equivalent. For example, FridayParts blower motor replacement cost often ranges from $60 to $200. Reputable suppliers ensure their parts meet or exceed OEM specifications.

- Cons: Quality can vary between manufacturers. It is crucial to buy from a trusted supplier with a strong reputation and good warranty support.

Other Key Factors That Influence Your Blower Motor Replacement Cost

Beyond the basic split of labor and parts, several specific factors will shape the final number on your invoice. Understanding these variables is crucial for accurately estimating your expenses and making cost-effective decisions.

1. Motor Specifications: The Core of the Cost

The technical details of the blower motor itself are a primary cost driver.

- Horsepower and Size: Just like in any other application, a more powerful motor costs more. A small motor for a compact skid steer will normally be cheaper than a high-output motor required for the larger cabin of a mining haul truck or a large excavator. You must ensure the replacement has the correct HP rating to perform effectively without being unnecessarily oversized and expensive.

- Type and Speed: The technology inside the motor plays a huge role in its price.

- Single-Speed Motors: These are the most basic and least expensive options, typically found in older or more utilitarian machines.

- Multi-Speed and Variable-Speed Motors: These more advanced motors offer greater control over airflow, comfort, and efficiency. They are standard in modern equipment but come with a higher upfront cost.

2. Warranty Coverage

An existing warranty can drastically reduce your out-of-pocket expenses.

- Machine Factory Warranty: If your equipment is relatively new and still under its original warranty, the cost of the blower motor part may be fully covered. Typically, you would still be responsible for the labor charges.

- Part Warranty: When purchasing a replacement, especially an aftermarket one, check the warranty offered by the supplier. A good warranty provides peace of mind and protects you against premature failure, ensuring you only have to pay for the part once.

3. Diagnostic Fees and Accuracy

Before any work begins, the root cause of the failure must be identified. This diagnostic process is a service and involves a charge.

- Initial Inspection Cost: Most repair shops or mobile technicians charge a flat fee or at least one hour of labor to diagnose the problem. This includes testing the switch, fuses, wiring, and resistor to confirm the blower motor truly has failed.

- The Cost of Misdiagnosis: An incorrect diagnosis can be costly. If a less experienced technician replaces the motor when the actual problem was a $50 resistor or a bad ground wire, you’ll pay for an unnecessary part and labor, but the problem may remain.

4. Associated Component Replacement Costs

A failing blower motor can often damage other parts or be damaged by them. A skilled technician will suggest replacing these parts at the same time to prevent future failures and save on additional labor.

- Blower Motor Resistor: The most common related replacement. The resistor controls the fan speeds. It usually fails before the motor, causing the fan to only operate on high. Replacing it with the motor is a wise preventative step.

- Cabin Air Filter: A heavily clogged filter restricts airflow and causes the blower motor to work harder and overheat, which can lead to early failure. Replacing a dirty air filter is an inexpensive and essential step to protect your new motor.

- Switches and Wiring: Sometimes, a failing motor can draw excessive current, damaging the dashboard fan control switch or melting parts of the wiring harness. These repairs will add to the cost on top of the motor replacement.

5. Geographic Location and Service Type

Where the repair takes place directly influences the price.

- Regional Labor Rates: Labor costs can vary greatly depending on the region. A technician in a large city will generally have a higher hourly rate than one in a rural area.

- Mobile vs. In-Shop Service: If your machine is at a remote site, you’ll pay for a mobile technician’s travel and a service call fee, which can significantly increase the bill. This is often more costly than bringing the machine to a repair shop, but it might be the only feasible option.

6. Machine Age, Part Availability, and Urgency

Your machine’s age and operational needs can affect costs.

- Older or Rare Models: Finding parts for a 20-year-old machine or a less common brand can be difficult. The part may be discontinued, requiring you to find a “new old stock” or a used part from a salvage yard, affecting price and delivery time.

- Expedited Shipping and Emergency Fees: If the machine is vital to your operations and downtime costs you money every hour, you will likely pay more for overnight or fast shipping. Emergency or after-hours service will also cost more in labor.

How to Save on the Blower Motor Replacement Cost?

Even though this repair can be pricey, there are ways to manage costs:

- Opt for Quality Aftermarket Parts: This is the most effective way to reduce your bill. Getting a reliable aftermarket motor from a trusted supplier like FridayParts can halve your part costs without sacrificing quality.

- Regularly Maintain: Dust and debris are the main enemies of a blower motor. Regularly cleaning or replacing your cabin air filter can lessen the motor’s workload and prolong its lifespan.

- Bundle Repairs: If the technician is already working on the HVAC system, inquire about replacing other worn parts like the resistor or filters at the same time.

- Get Multiple Quotes: Contact several qualified repair shops or mobile mechanics to compare their prices and estimates.

- Make Sure of the Diagnosis: Demand an accurate diagnosis. Don’t let a mechanic start replacing parts without confirming the root cause.

Should You Replace a Blower Motor Yourself?

For experienced mechanics, replacing it DIY-style is possible and can significantly cut labor costs. However, for most equipment owners, we strongly recommend against it.

Risks of DIY

- Misdiagnosis: You might end up replacing a good motor when the problem was a cheap resistor, fuse, or switch.

- Causing Additional Damage: Modern machines have complex electrical systems. An incorrect installation could damage a control module, resulting in a repair bill ten times higher than the original job.

- Safety Concerns: Disconnecting electrical parts can be dangerous if not done properly.

- Time and Frustration: What a professional can do in 2 hours might take you an entire weekend, leading to more downtime.

Hiring a pro ensures the job is done right, efficiently, and often includes a warranty on parts and labor.

Why Replace Your Blower Motor?

Delaying replacement is more than an inconvenience; it poses risks.

- Operator Comfort and Efficiency: An operator dealing with extreme heat or cold is less attentive and productive.

- Safety and Visibility: A working blower motor is crucial for the defroster. A foggy or icy windshield creates a safety hazard on any job site.

- Avoiding Further Damage: A seizing or electrically failing motor can overload circuits, blow fuses, or damage the resistor and control switches, complicating repairs.

When to Replace Your Blower Motor?

Your machine signals when the blower motor is failing. Watch for these signs:

- Weak or No Airflow: Even on high, minimal air comes from the vents.

- Unusual Noises: Squealing, grinding, or rattling sounds often indicate a worn motor, especially if they change with fan speed.

- Motor Only Works on High Speed: This suggests the blower resistor has failed, putting extra stress on the motor and often leading to complete failure.

- Burning Smell or Smoke: A plastic or electrical burning smell is a serious warning. Turn off the system immediately and have it inspected, as this indicates overheating and potential fire risk.

Conclusion

Replacing the blower motor in heavy equipment is essential for operator safety and efficiency. Although the cost in 2025 may be high, knowing factors like labor and part cost, and other key factors that influence the replacement cost helps reduce expenses. For example, choosing a high-quality aftermarket part from FridayParts can provide OEM-quality performance at a lower cost.

At FridayParts, we offer top aftermarket blower motors and resistors compatible with many heavy equipment brands. Our parts aim to match or exceed OEM quality without OEM prices. Visit fridayparts.com to find the right part for your machine and get it back to work affordably.