A fuel filter prevents harmful contaminants like dirt, rust, and water from entering your fuel system. Over time, however, the filter becomes clogged, which can make your machine hard to start, cause power loss under load, or lead to rough idling and sputtering. At this time, you need to replace your fuel filter as soon as possible. However, many people want to save on fuel filter replacement costs, which ultimately leads to more serious damage. This raises a question: What is the cost of a fuel filter replacement in 2025? And how much can you save by replacing it yourself promptly? Follow this article to know how.

What Makes Up the Cost of a Fuel Filter Replacement?

There are mainly two categories that constitute the fuel filter replacement cost: labor and parts. For heavy machinery like excavators, loaders, or tractors, both can vary more than they would for a standard passenger vehicle.

Labor Cost

Replacing a fuel filter on heavy equipment isn’t always a simple, 10-minute job. The filter’s location, the number of filters in the system, and the need to bleed air from the lines all impact the complexity and, therefore, the cost.

- Hourly Rates: A qualified heavy equipment technician typically charges between $100 and $200 per hour, depending on the replacement complexity.

- Time Required: An easy replacement of a single, accessible fuel filter might take only 30 minutes. However, if the machine has a multi-stage system, like a primary filter, secondary filter, and water separator, etc, and requires bleeding the fuel system afterward, the job could easily extend to 1.5 to 2 hours.

As a result, the estimated labor cost is in the range of $50 to $400, without adding the diagnostic fees.

Parts Cost

The filter itself is the other major part of the replacement cost. Here, you have a choice to make between OEM and aftermarket parts, which will vary a lot.

OEM Parts

OEM parts are made by the same company that built your machine, including Caterpillar, John Deere, Komatsu, and more.

- Pros: They guarantee a perfect fit and are often considered the “safest” option for performance and warranty compliance.

- Cons: They come with a premium price tag. Depending on the machine, a single OEM fuel filter can cost $80 to $300 or more, especially for advanced filtration systems or kits.

Aftermarket Parts

Aftermarket parts are produced by third-party companies. They are designed to function identically to OEM parts and are often the smartest choice for out-of-warranty repairs.

- Pros: The primary advantage is cost. A high-quality aftermarket fuel filter can be 40-70% cheaper than its OEM equivalent. For example, reputable aftermarket fuel filters, such as those from FridayParts, often range from $15-$120. Top suppliers ensure their parts meet or exceed OEM specifications for crucial metrics like filtration efficiency and flow rate.

- Cons: Quality can vary between manufacturers. So, it is crucial to buy from a trusted supplier with a strong reputation and good warranty support to ensure your engine remains protected.

Additional Factors That Influence Your Fuel Filter Replacement Cost

Apart from basic labor and parts costs, several other factors can influence your fuel filter replacement cost. Knowing these variables is essential for accurate cost estimation and making economical choices for your heavy equipment.

1. Filter System Complexity & Technology

The technical details of your machine’s fuel system significantly impact the cost. Not all fuel filters are the same.

- Single-Stage vs. Multi-Stage Systems: Smaller, older machines may have a single fuel filter, but most modern heavy equipment uses a multi-stage setup:

- Primary Filter/Water Separator: This is the first defense, typically rated at 10 to 30 microns, designed to remove larger contaminants and water.

- Secondary Filter: A finer filter, usually rated at 2 to 5 microns, protects sensitive high-pressure fuel injectors.

Replacing the entire set costs more than a single filter but is vital for engine health.

- Filtration Technology: Modern Tier 4 Final / Stage V engines demand extremely clean fuel. High-efficiency filters that capture microscopic particles are more costly than the simpler filters used in older, mechanically injected engines.

- Integrated Components: Many modern fuel filter units are complex, including a housing, built-in priming pump, and a Water-in-Fuel sensor. If the housing cracks or the sensor fails, replacing the whole assembly is much more expensive than just the filter element.

2. Warranty Coverage

A current warranty can significantly lower your out-of-pocket costs.

- Machine Factory Warranty: If your equipment is new and under the original manufacturer’s warranty, the costs for parts and even labor might be fully covered. Always review your warranty terms first.

- Part Warranty: When buying a replacement, especially an aftermarket part, confirm the warranty from the supplier. A solid warranty offers peace of mind and shields you from premature failure, ensuring you pay only once for the part.

3. Diagnostic Fees and Accuracy

Proper diagnosis is crucial before replacing parts.

- Initial Inspection Cost: Most repair shops or mobile technicians charge a flat fee or at least one hour of labor ($100-$200) for diagnosis, which includes checking fuel pressure, looking for air leaks, and confirming if a clogged filter is causing the issue.

- The Cost of Misdiagnosis: An incorrect diagnosis can be costly. Replacing fuel filters when the real problem is a weak lift pump or clogged tank vent wastes money and does not fix the issue.

4. Replacement Costs for Related Components

A skilled technician may inspect related parts and suggest replacing them simultaneously to prevent future failures and save on future labor.

- Water Separator Bowl and Seals: The plastic bowl on a water separator can become brittle, crack, or get damaged during removal. Its seals can also perish. Replacing these with the filter is a common and wise practice.

- Fuel Lines and Fittings: During filter replacement, old and hardened fuel lines or leaking fittings may be found. Replacing them now avoids future leaks and breakdowns.

- Priming Pump: If the manual priming pump leaks fuel or fails to build pressure, it should be replaced during service.

5. Location and Service Type

Where and how your repair occurs directly impacts the cost.

- Regional Labor Rates: Labor costs differ greatly by region. Technicians in metro areas often charge higher hourly rates than those in rural areas.

- Mobile vs. In-Shop Service: Mobile technicians coming to your site add travel time and a service call fee, which can increase the bill by $150 or more. This may be costlier than taking the machine to a shop, but it is sometimes the only option for immobile equipment.

6. Machine Age, Part Availability, and Urgency

The age of your machine and how critical the repair is can influence the final cost.

- Older or Rare Models: Finding a specific filter housing for a 20-year-old machine can be difficult. The part might be discontinued, requiring a used or salvage yard part, affecting price and availability.

- Expedited Shipping and Emergency Fees: If your equipment is down and costing thousands daily, you’ll likely pay premium prices for overnight shipping and emergency after-hours service.

When Should You Replace Your Heavy Machinery’s Fuel Filter?

Unlike a car’s mileage-based schedule, maintenance on heavy equipment is tracked in service hours. Typically, fuel filters should be replaced every 500 service hours, but this can vary. Always refer to your machine’s operator and maintenance manual for specific recommendations.

Signs You Need to Replace the Fuel Filter

A clogged or failing fuel filter will restrict fuel flow to your powerful diesel engine. When the filter is compromised, you’ll notice clear performance problems:

- Engine Power Loss: The most common sign. The machine feels weak, especially when digging, climbing a grade, or operating hydraulics under load.

- Hard Starting: The engine cranks for a long time before starting or may not start at all.

- Engine Sputtering or Stalling: The engine runs unevenly or stalls completely, especially when demanding more power.

- Excessive Black Smoke: Indicates incomplete combustion caused by a restricted fuel supply.

- Visible Contamination: Dirt, debris, or a significant amount of water can often be seen in the clear bowl of your primary filter/water separator.

If you want to know more detailed symptoms, you can read: 10 Common Symptoms of a Clogged Fuel Filter.

Why You Shouldn’t Ignore It: The Risks of Delay

A clean fuel filter is crucial for protecting your engine’s advanced fuel system. Modern diesel engines, especially Tier 4 Final models, use High-Pressure Common Rail systems with tolerances measured in microns.

Ignoring a clogged filter lets microscopic dirt and water enter the system, leading to:

- Major Injector Damage: Debris can destroy the internals of your fuel injectors. Repair costs can range from $3,000 to $8,000 or more.

- Fuel Pump Damage: The high-pressure fuel pump is equally vulnerable. Repairs can cost thousands.

- Costly Downtime: A machine that’s not running means lost revenue.

Compared to the $40-$150 cost of new filters, avoiding costly repairs by routine replacement is a smart investment in your machine’s lifespan.

How to Save on the Fuel Filter Replacement Cost?

The simplest way to cut costs is to do the replacement yourself. While parts are necessary, you can eliminate the $100-$400 labor cost by handling this important maintenance task on your own.

Can You Replace the Fuel Filter Yourself?

Yes, for most machine owners, this is a manageable DIY task. It requires basic mechanical skills, the right tools, and attention to cleanliness. Spending about an hour doing it yourself saves money and gives you a better understanding of your equipment.

DIY Fuel Filter Replacement: A Step-by-Step Guide

While the exact location and type of filter may differ between a skid steer, excavator, or dozer, the general process remains the same.

Safety First: Work in a clean, well-ventilated area. Wear nitrile gloves to protect your skin from diesel fuel, and keep a fire extinguisher nearby as a safety precaution.

1. Prepare the Machine

Park on level ground, lower all attachments, engage the parking brake, shut down the engine, and, if applicable, turn off the battery disconnect switch.

2. Locate the Filter

Check your manual. You’ll usually find one or two filters. A primary filter/water separator is often mounted on the frame, while a secondary filter is typically near the engine.

3. Clean the Area

This step is critical. Use compressed air or a clean rag to thoroughly clean the filter housing and the surrounding area. This prevents dirt from contaminating the fuel system when removing the old filter.

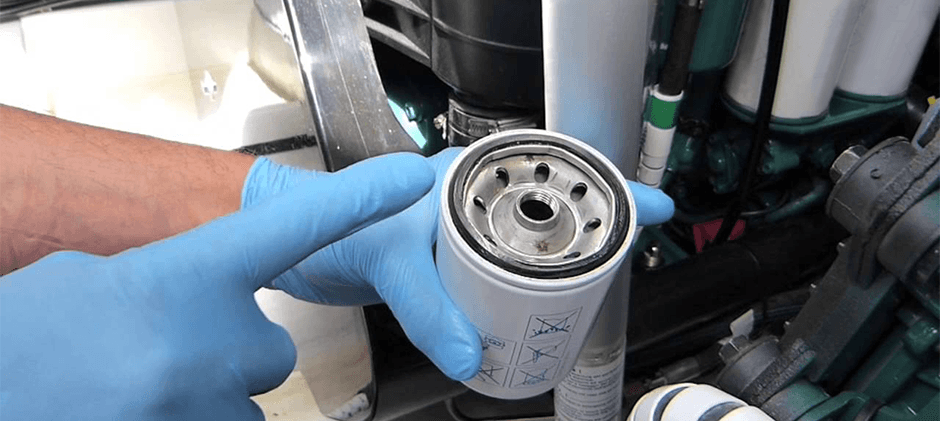

4. Remove the Old Filter

Place a drain pan underneath to catch spilled fuel. Use a filter wrench to loosen the old filter. If your water separator has a reusable bowl, carefully unscrew it and set it aside for cleaning.

5. Install the New Filter

- Apply a thin layer of clean diesel fuel or motor oil on the rubber gasket to ensure a good seal.

- Pre-fill the new filter with clean diesel fuel to make priming easier and avoid damaging the high-pressure pump.

- Screw the new filter on by hand until the gasket contacts the base, then tighten an additional 1/2 to 3/4 turn with the filter wrench. Do not overtighten.

6. Prime the Fuel System

Locate the manual priming pump, usually a small plunger on top of the primary filter housing. Pump repeatedly until you feel firm resistance, indicating the filter is full and air is purged. You may also need to open a bleed screw on the filter housing while priming—check your manual.

7. Start and Inspect for Leaks

Start the engine. It may run rough for a few seconds as the last bits of air are purged from the system. Once it smooths out, carefully inspect the new filter and all connections for any signs of fuel leaks. If you see any, shut down the engine immediately and tighten the connections.

Conclusion

The cost of replacing a fuel filter can vary widely depending on the make and model, part choice, regional labor rates, and other factors. In 2025, it typically ranges from $65 to $700 for a professional replacement. It seems expensive, but fortunately, there are also many ways to reduce the replacement cost.

Firstly, if you replace it yourself, you can save $50 to over $400 by eliminating professional labor costs. Secondly, if you buy aftermarket fuel filters from a reliable supplier like FridayParts, you can save 40% to 70% on the part itself compared to OEM dealer prices without compromising quality. Additionally, FridayParts fuel filters have a one-year warranty and a 90-day return period to safeguard your rights. Visit our website and shop now!