If you work with off-highway equipment, you’ve likely encountered thermostat replacements more than once. A quick online search often reveals a puzzling range of prices—some surprisingly low, others shockingly high. This wide gap usually comes down to several key factors: part quality, labor rates, machine model, and even hidden fees. Knowing what really drives the cost of thermostat replacement is essential if you want to avoid overspending.

In this guide, we’ll walk you through the expected thermostat replacement costs for 2025 and break down what influences those prices, from parts and labor to equipment type. You’ll also learn smart ways to cut repair costs and avoid unnecessary replacements, helping you keep your heavy equipment running efficiently without breaking the bank.

Key Takeaways

- Total Cost: Expect the total thermostat replacement cost to range from $170 to $450 in 2025, including parts and professional labor.

- Parts Cost: The thermostat itself is inexpensive, typically costing between $20 and $150, depending on the type.

- Labor Cost: Professional labor is the biggest factor, usually running from $150 to $300, based on how hard it is to access the part.

- DIY Savings: Replacing it yourself can save you at least $ 150 on labor, but it requires the right tools and technical confidence.

- Hidden Costs: Always budget for fresh coolant and a new gasket; these are essential for doing the job right.

Why Thermostat Matters in Off-Road Equipment?

The thermostat is a small but essential valve that regulates coolant flow between the engine and the radiator, helping your off-road machine maintain optimal operating temperature. When it fails, it can cause serious problems. If the thermostat gets stuck closed, the engine may overheat, potentially leading to warped cylinder heads, blown head gaskets, or even complete engine failure. On the other hand, if it gets stuck open, the engine may never reach its ideal temperature, resulting in poor fuel efficiency, increased engine wear, and higher emissions. This makes timely thermostat replacement not just important, but critical for engine performance and long-term reliability.

Average Thermostat Replacement Cost in 2025

Calculating the exact thermostat replacement cost can be tricky because it depends heavily on the specific machine. Unlike cars, where models are somewhat standardized, the world of heavy equipment—from a compact skid steer to a 50-ton excavator—is incredibly diverse. However, as of 2025, the replacement cost of a thermostat can probably be determined within a reasonable price range.

For most common off-road machinery, you can expect the total professional thermostat replacement cost to be between $170 -$450. This range can be broken down into two main parts: the cost of the parts and the cost of labor.

Parts Cost: $20 – $150+

The thermostat itself is a relatively low-cost item. However, the price can vary. A simple mechanical thermostat for a smaller diesel engine might be on the lower end, while a more complex, electronically controlled thermostat for a modern Tier 4 Final engine will be at the higher end of that range. You also must include the cost of a new gasket and several gallons of fresh engine coolant.

Labor Cost: $150 – $300+

This is where the cost varies the most. Heavy equipment mechanics typically charge between $100 and $175 per hour. A thermostat replacement can take anywhere from 1.5 to 4 hours, depending entirely on its location. On some engines, the thermostat housing is easily accessible right on top. On others, it might be buried behind pumps, hoses, and other components that must be removed first, significantly increasing the labor time.

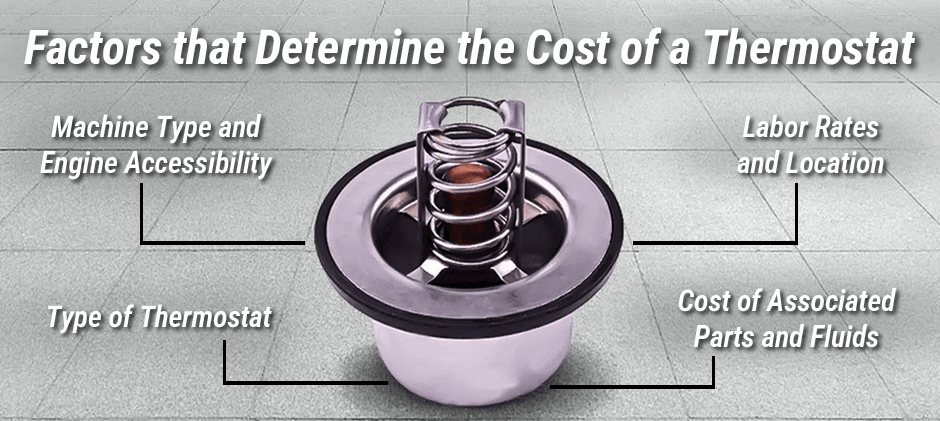

Factors that Determine the Cost of a Thermostat

Now that we have a general idea of the cost, let’s dig into the specific factors that can push your thermostat replacement cost to the lower or higher end of the spectrum. Understanding these variables will help you know what to expect when you get a quote.

1. Machine Type and Engine Accessibility

This is the single biggest factor influencing labor costs.

- Easy Access: On some engines, like many in the Cummins B-Series, the thermostat housing is right on top of the engine, held on by two or three bolts. A mechanic can perform this job relatively quickly.

- Difficult Access: On other machines, especially those with compact engine bays designed to meet modern emissions standards, the thermostat can be buried. The mechanic may need to remove the alternator, belts, brackets, and extensive hoses just to reach it. This adds hours to the job and is the primary reason for a high labor bill.

2. Type of Thermostat

Not all thermostats are the same.

- Standard Mechanical Thermostat: This is the most common and affordable type. It’s a simple, self-contained wax-pellet valve.

- Electronically Controlled Thermostat: Newer, more advanced engines use thermostats that are controlled by the Engine Control Module (ECM). These units are more complex, often integrated into a larger housing, and are significantly more expensive to purchase.

3. Labor Rates and Location

Where you get the work done matters. A specialized heavy equipment dealer will likely have higher labor rates than an independent heavy equipment mechanic. Likewise, rates in major urban centers are typically higher than in rural areas.

4. Cost of Associated Parts and Fluids

A professional job involves more than just the thermostat itself. These necessary add-ons will be part of your final bill.

- Gasket or Seal: The seal between the thermostat housing and the engine must always be replaced to prevent leaks.

- Thermostat Housing: Sometimes the housing itself can be corroded or cracked, especially on older machines. If it needs to be replaced, this will add to the parts cost.

- Engine Coolant: Replacing a thermostat requires draining a significant amount of coolant from the system. It is best practice to refill the system with fresh, new coolant rather than reusing the old fluid. This ensures the entire cooling system is protected. Depending on the size of your machine, this can require 5 to 15 gallons of coolant.

Component Cost Estimates

| Component | Estimated Cost |

|---|---|

| Thermostat | $20 – $150 |

| Electronically Controlled Thermostat | $100 – $250+ |

| Thermostat Gasket / Seal | $10 – $35 |

| Thermostat Housing | $30 – $150 |

| Engine Coolant / Antifreeze | $25 – $100+ |

DIY vs. Professional Thermostat Replacement

Faced with a potential labor bill of several hundred dollars, it’s tempting to consider replacing the thermostat yourself. For many equipment owners with mechanical skills, this is a very achievable and cost-effective option.

Doing It Yourself (DIY)

Pros:

- Huge Cost Savings: Your only cost is the parts and your time. You can save anywhere from $150 to $500 in labor.

- Reduce unnecessary expenses: You can do it yourself and avoid being advised to carry out unnecessary repairs or extra charges.

- Discover potential problems: During the disassembly and inspection process, other potential problems may be discovered and solved in advance.

Cons:

- Risk of Complications: You could snap a rusty bolt, install the gasket incorrectly, causing a leak, or—most critically—fail to bleed the air out of the cooling system properly after refilling. An air pocket can cause the engine to overheat even with a new thermostat.

- Time: What might take a pro 2 hours could take you 4-5 hours, especially if it’s your first time.

If you are considering this route, a step-by-step guide can be invaluable. For example, our guide on a 2012 Cummins Thermostat Replacement: A Step-by-step Guide shows the level of detail involved.

Hiring a Professional

Pros:

- Peace of Mind: The job is done correctly by an experienced technician.

- Workmanship Warranty: Most shops offer a warranty on their labor, so if a leak develops, they will fix it.

- Proper Tools and Procedures: They have the right equipment and know the specific procedure for bleeding the cooling system on your machine.

Cons:

- Scope Restrictions: Repairs must be performed at a legitimate and authorized repair facility; failure to do so may void the device’s warranty or usage.

- Long Waiting Times: You’ll need to schedule an appointment or wait for a professional technician to arrive, which can be more time-consuming than performing the repair yourself.

- Cost and Hidden Costs: Labor costs are significantly higher, and some repair providers may delay repairs or recommend additional services, resulting in higher costs.

How to Save on Thermostat Replacement Cost?

Whether you go the DIY or professional route, there are smart ways to manage the cost:

- Buy High-Quality Aftermarket Parts: You don’t need to pay the high OEM price. A reputable aftermarket supplier can provide a high-quality thermostat that meets or exceeds OEM specifications for a fraction of the cost. This is also the choice of most people at present.

- Bundle the Job: If you’re paying for the labor to access the thermostat, consider replacing other nearby worn items at the same time. This could include radiator hoses, the serpentine belt, or even doing a full coolant flush. This saves on future labor costs.

- Get Multiple Quotes: If you’re hiring a professional, call at least two or three shops to get quotes. You may find a significant price difference.

- Do the Easy Parts Yourself: Even if you don’t want to do the full replacement, you could save a little by purchasing the parts yourself and bringing them to an independent mechanic who allows customer-supplied parts.

Based on real customer feedback, third-party parts are often a smart alternative. One of our customers, Jack, initially ordered a part from a dealer at a high price. After some negotiation, the price dropped, but he later found out he had still overpaid. He then switched to a third-party supplier and was surprised to find the quality nearly identical to OEM, but at a much better price. That’s also exactly what FridayParts aims to offer: high-quality service and great value.

When Does Your Thermostat Need Replacing?

Your machine will usually give you clear signs that the thermostat is failing. It’s crucial to distinguish these signs from other cooling system problems. Sometimes, the issue might be with the water pump or a sensor. Our article, How to Tell If Your Water Pump or Thermostat Is Failing?, can help you diagnose the problem more accurately.

Key symptoms of a bad thermostat include:

- Engine Overheating: The temperature gauge climbs into the red zone, especially under load. This is the classic sign of a thermostat stuck closed.

- Engine Running Too Cold: The temperature gauge never reaches the normal operating range. This indicates a thermostat stuck open.

- Erratic Temperature Fluctuations: The gauge swings wildly between hot and cold.

- Poor Heater Performance: In cabs with heaters that use engine coolant, a thermostat stuck open can lead to lukewarm air from the vents.

It’s also important to understand the difference between a thermostat and a temperature sensor. A bad sensor can give you a false reading, making you think the thermostat is bad. Our guide, Temperature Sensors VS Thermostats: What is the Difference?, explains this in detail.

Conclusion

Overall, the cost of replacing a thermostat in 2025 will remain in the range of $170-$450. Anything above this price will require careful consideration. While the thermostat replacement cost for heavy equipment can seem significant, it’s a small price to pay for engine protection and operational reliability. A failing thermostat is not a problem to ignore. Addressing it promptly protects your investment and keeps your projects on schedule.

For a cost-effective solution without compromising on quality, turn to FridayParts. We offer a vast inventory of high-quality aftermarket thermostats and cooling system components for all major heavy equipment brands. Get the reliable parts you need at an affordable price to keep your machine running at the perfect temperature.