A hydraulic solenoid valve controls the flow, direction, and pressure of hydraulic fluid in a system. It uses an electromagnetic coil to move a plunger, which opens or closes ports to regulate fluid movement. This precise control ensures efficient operation of hydraulic actuators, such as cylinders, motors, and pumps. The parts play a crucial role in applications requiring precise movement control, pressure regulation, and safety shut-off functions. So, they are widely used in construction equipment, agricultural machinery, industrial automation, aerospace systems, and material handling equipment. In this article, we’ll dive into everything you need to know about it, including how a hydraulic valve works, how to tell if it’s bad (symptoms & troubleshooting), and how to select the right one.

Shop at FridayParts

What Is a Hydraulic Solenoid Valve?

A hydraulic solenoid valve is an electromechanically operated valve used to control the direction, pressure, and flow of hydraulic fluid within a system. It consists of a solenoid (an electromagnetic coil) that activates the valve by generating a magnetic field when energized. This action moves a plunger, opening or closing ports to regulate fluid movement.

Key Functions:

- Directing hydraulic fluid to different actuators

- Controlling pressure to prevent system overload

- Enabling or disabling fluid flow for safety and efficiency

How Does a Solenoid Valve Work?

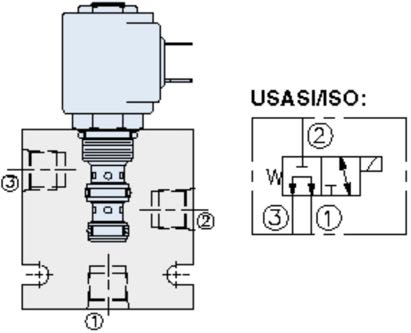

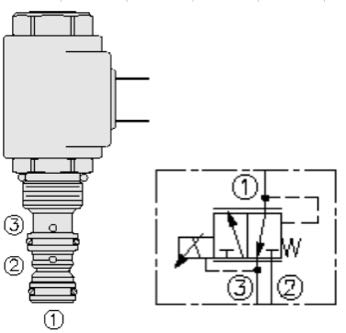

The picture above illustrates the components of a hydraulic solenoid valve. The solenoid valve has closed cavities, holes in various places that are each connected to a different oil pipe, a piston in the middle, two electromagnets on either side, and depending on which side of the magnet coil is energized, the valve body will be drawn to that side. The valve body can be moved to open or close the various drain holes, and since the inlet hole is always open, hydraulic oil will enter the various drain holes. The mechanical mechanism is driven by the piston, which in turn drives the piston rod. In this way, mechanical movement is controlled by the current flow of the solenoid.

How to Tell If a Hydraulic Solenoid Is Bad? Common Problems & Troubleshooting of Hydraulic Solenoid Valves

To tell if your solenoid is bad, you should recognize the symptoms of a bad solenoid. A faulty hydraulic solenoid valve can cause system malfunctions, leading to poor operating failure. If you are not sure about what went wrong, here is the troubleshooting process.

- Failure to Activate – The valve doesn’t respond when powered, indicating electrical issues like a blown fuse, damaged wiring, or coil burnout.

- Sluggish or Delayed Operation – The valve takes longer than usual to switch, often due to low voltage, weak coil, or contaminated hydraulic fluid.

- Stuck in One Position – The valve remains open or closed, possibly caused by internal debris, worn-out seals, or coil failure.

- Overheating – Excessive heat from the solenoid coil suggests continuous operation, voltage fluctuations, or coil short-circuiting.

- Unusual Noises – Buzzing or clicking sounds may indicate loose components, coil damage, or unstable electrical signals.

- Leaking Hydraulic Fluid – Worn-out seals or damaged valve components can lead to fluid leakage, reducing system efficiency.

- Inconsistent Pressure or Flow – The system experiences irregular fluid flow or pressure fluctuations, pointing to internal blockages or valve wear.

To troubleshoot these problems, operators should inspect electrical connections, replace damaged coils, ensure adequate pressure levels, and maintain clean hydraulic oil to prevent contamination-related failures.

How to Choose the Right Hydraulic Solenoid Valve?

Here are 3 main types of the solenoid valve:

- 12V Solenoid Valves → Ideal for mobile equipment and off-road machinery.

- 24V Solenoid Valves → Common in industrial automation and heavy-duty applications.

- High-Pressure Valves → Designed for extreme hydraulic loads and high-stress environments.

Selecting the suitable hydraulic solenoid valve for your machinery is not as hard, there are a few factors to consider, such as voltage requirements, pressure capacity, and application needs. In general, there are 2 types of solenoid valves, 12V, 24V, and high-pressure solenoid valves.

12V hydraulic solenoid valves are commonly used in mobile equipment and off-road machinery due to their compatibility with vehicle electrical systems. 24V hydraulic solenoid valves, on the other hand, are widely used in industrial automation and heavy-duty applications where higher voltage operation is preferred. For high-pressure systems, specialized high-pressure solenoid valves are designed to withstand extreme hydraulic loads, ensuring durability and efficiency in demanding environments.

Solenoid Valve FAQs

Can You Fix a Faulty Solenoid Valve?

Yes, but it depends on the problem. Some issues, like dirt buildup or minor electrical faults, can be fixed easily. Cleaning the valve or replacing a worn-out coil might solve the issue. However, if the internal parts are damaged, a full replacement may be the best option.

What Is the Lifespan of a Solenoid Valve?

It varies based on usage and maintenance. A well-maintained valve can last several years without trouble. Regular cleaning and checking for wear can extend its life. However, heavy use or exposure to harsh conditions can shorten its lifespan.

How to Replace a Solenoid Valve?

How to Replace a Solenoid Valve? When to Replace It? An Ultimate Guide!

Register Now to Get Exclusive Coupons

Conclusion

A hydraulic solenoid valve is a critical component in a hydraulic system, I believe that after reading this article, you have a full understanding of its function, different types, and potential troubleshooting methods.

FridayParts has updated the blog to make sure you got everything you need to know about the hydraulic solenoid valve. What we got is not only our professionalism, but also our sincere concern and care for every one of our customers. If you have any questions about heavy equipment, feel free to visit the FridayParts blog. You are also good in hand with our products. All the hydraulic components sold in the website meet OEM standards with the best prices. If you need a replacement hydraulic solenoid valve, just go check our store, they are the real deal!