Removing an oil filter isn’t difficult, but your tools are crucial. The right oil filter wrench can save you a lot of trouble, but choosing the wrong tool could damage the filter. If you’re removing an oil filter yourself for the first time, this guide will be very helpful. We’ll detail the different types of oil filter wrenches and show you how to choose the best one for your machine.

Types of Oil Filter Wrenches

Not all oil filter wrenches are the same. Every design has its own advantages and disadvantages; for example, when dealing with a big, heavy filter on off-road equipment or in a narrow engine room, these pros and cons become more apparent. Below is the most common type you will meet.

1. Oil Filter Cap Wrench

This is one kind of socket-style wrench, designed for a perfect fit to the special oil filter end part. It can catch the groove (flat face on end cap), and you can drive it with a standard 3/8 inch or 1/2 inch ratchet or breaker bar.

- Pros: Gives the best gripping power, spreads the force evenly so as to avoid crushing the filter can, and is not easy to slip down. When you can see clearly and touch the filter end, it is an ideal choice.

- Cons: Size is limited. A cap wrench for a 93 mm filter cannot be used on a 95 mm filter. This means you need to prepare a different cap for every equipment.

2. Oil Filter Pliers

This kind of plier looks like a big size slip-joint plier, the jaw is bending, and the tooth shape is clear. Because of the long handle, they have very high adjustability and also very good lever force.

- Pros: The Use scope is wide, can grip many different sizes of filters. A long handle can help to reach a filter that is not suitable.

- Cons: They squeeze the canister to grip the filter, but if they apply too much force, they can easily crush or puncture it. Also, the jaw can easily slip, especially when you grip an oily filter, so it does not provide as much safety as a cap wrench if the filter really sticks; you should treat it as a last resort.

3. Oil Filter Spider Wrench

This unique tool typically has three adjustable legs that tighten their grip on the filter as you turn the central drive mechanism with a ratchet. It’s a self-tightening design.

- Pros: Offers a universal fit for a range of filter sizes. It’s excellent for tight spaces where you can’t swing the long handles of pliers, as it only requires room for a ratchet.

- Cons: The legs need a firm surface to grip and may slip on filters that are badly damaged or very smooth. They can also crush a filter if it is thin-walled.

4. Oil Filter Chain or Strap Wrench

This classic heavy-duty tool uses a loop of chain or a high-strength fabric strap connected to a handle. The loop is placed around the filter, and as the handle is turned, the loop tightens and grips the canister.

- Pros: Extremely versatile and can handle a very wide range of diameters, from small filters to the very large ones found on heavy diesel engines. They can generate immense torque.

- Cons: They require a significant amount of clearance around the filter to wrap the chain/strap and swing the handle. They are also very likely to crush or deform the filter canister, making them suitable only for removal, never for installation.

What Size Oil Filter Wrench Do I Need?

For a professional and no-damage way to change oil, the best choice is an oil filter wrench with the proper size. It can make sure that all the torque you apply directly turns the filter without deforming it.

So, how do you decide the exact size you need? You cannot only rely on a guess. Looking for the filter part number may give some specification info, but the most reliable way is to measure the filter you are using directly. This way can remove all doubt, and guarantee you one one-time buy tool with a perfect match. The next part will guide you to finish this simple but very important process.

Note: Using a tool with the wrong size will bring disaster. Too big a wrench will slip down and make it harder to remove. Too small a wrench, then it cannot take it out. Although universal tools like pliers or chain wrenches have flexibility, they also have a big risk of pressing a broken filter, which may make a mess and a tricky situation.

How to Measure Your Oil Filter?

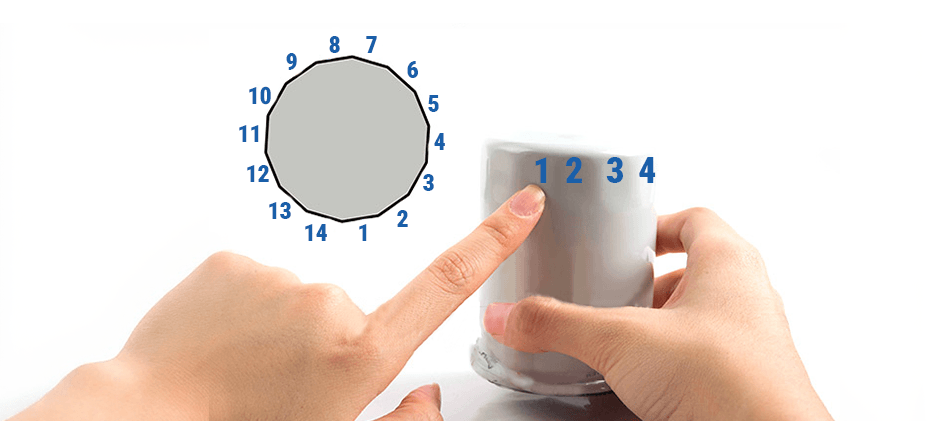

To find the perfect cap-style oil filter wrench, you need two key measurements: the number of flutes and the diameter. This two-part specification ensures a snug, no-slip fit.

Step 1: Count the Flutes

The flutes are the flat surfaces or facets on the end of the oil filter canister. They are what the wrench grips onto. Carefully count the number of these flutes. A common number for many filters is 14 or 15, but this can vary widely. In the example image, you can see the filter has 14 distinct flutes.

Step 2: Measure the Diameter

Using a pair of digital calipers is the most accurate way to measure the filter’s diameter. As shown in the reference image, you need to measure from one flat flute surface directly across to the opposite flat flute surface. Do not measure from point to point, as this will give you an incorrect, larger reading. In the example, the measurement is 64.94mm.

Step 3: Combine the Measurements

The size of the cap wrench is expressed by combining these two numbers. For the filter in our example (64.94mm and 14 flutes), you would look for a 65mm x 14 Flute oil filter wrench. A slight difference in decimals is normal because manufacturers sell wrenches in standard millimeter sizes.

Having the right measurement is key to building your collection of hand tools. If you find your current wrench is worn or you need a new size, you can find a huge selection of affordable, high-quality aftermarket tools and accessories that match OEM specifications without the high dealer price tag.

Factors to Consider When Choosing

Beyond just the type and size, a few other factors will influence the best choice for your specific needs.

| Factor | What to Consider | Recommendation for Off-Road Machinery |

|---|---|---|

| Accessibility & Clearance | How much space is there around the filter? Is it buried deep in the engine bay? | If access is tight, a cap wrench or spider wrench with a ratchet extension is often superior to pliers or chain wrenches that require more room to maneuver. |

| Versatility | Do you work on multiple machines with different filter sizes? | A set of different-sized cap wrenches is the most professional solution. A chain wrench can serve as a versatile backup for odd sizes or extremely stuck filters. |

| Durability | Will the tool withstand high torque and heavy use? | Look for wrenches made from high-strength steel or heavy-duty aluminum. Avoid cheap, thin-stamped metal cap wrenches, as they can flex or crack under the torque needed for heavy equipment filters. |

| Filter Type | Is it a standard spin-on filter or a canister style with a replaceable element? | This guide focuses on spin-on filters. Canister systems have a permanent housing with a large nut that requires a standard large socket, not a specialized filter wrench. |

Tips for Using an Oil Filter Wrench Safely

To release the filter, first make sure you have a secure grip on it. Then, always turn the filter toward the left, that is, counter-clockwise, to remove it safely.

- Ensure a Secure Fit: Before you exert any force, make sure the wrench fully seats on the filter to avoid slipping accidents.

- Use for Removal Only: The oil filter wrench serves exclusively for the extraction of the oil filter. The novel filter ought to be installed manually. One should lubricate the novel gasket with fresh oil, and tighten it by hand until the gasket encounters the filter, subsequently adding three-quarters of a turn. If one uses the wrench to overtighten, the gasket may get damaged, leading to problems in the future. This damage can make the next oil replacement extremely difficult, turning a simple task into a frustrating and nightmarish process.

- Prepare for Spills: Before initiating the loosening of the filter, one must invariably situate an oil-receiving vessel beneath.

- Wear Gloves: Such action not only shields the hands from the affliction of heated oil but also bestows superior gripping power.

Get the Right Tool for the Job

To make the choice of a suitable oil filter wrench may appear only a small step, yet it can exert an influence of considerable magnitude upon your routine maintenance endeavors. Such a selection transforms what is otherwise a task of difficulty into one of rapidity and simplicity. By acquiring comprehension of the diverse filter types and by mastering the precise measuring method, you are thereby enabled to possess the most appropriate tool. There is no necessity for you to render to the dealer an excessive sum for the acquisition of these indispensable instruments. FridayParts is capable of furnishing durable and superior wrenches, together with other maintenance components, at an affordable cost, and they maintain abundant inventories to ensure compatibility with all brands of your heavy equipment.