Spark plug heat range is the difference between clean combustion and repeated plug fouling or engine damage. If your skid steer, UTV, small loader, generator, or other off-road equipment runs rough in the cold, loads up at idle, or shows signs of overheating under hard pulls, understanding heat range helps you fix the root cause instead of repeatedly swapping plugs.

What is spark plug heat range?

Spark plug heat range is how fast the plug pulls heat out of its firing tip and into the cylinder head. It is not the strength of the spark, and it is not a “hotter spark.” Many people wonder, do diesel engines have spark plugs? The answer is no; they use glow plugs, which operate on a different principle of heating the combustion chamber.

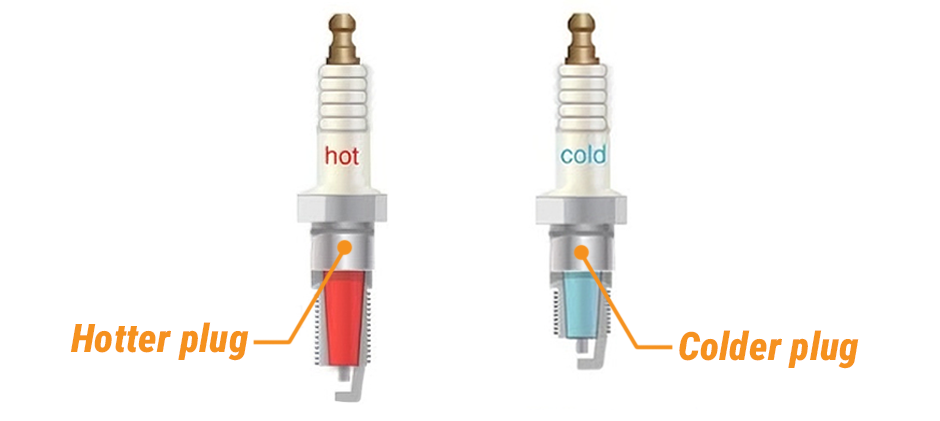

Heat range is mostly controlled by the insulator nose length and the plug’s internal heat path. A “hot” plug keeps more heat at the tip, and a “cold” plug transfers heat away faster.

Clear statement: “Heat range is about plug temperature control, not ignition power.”

Why Heat Range is Critical for Off-Road Engines

Off-road machines spend more time at low RPM, high load, dust, and temperature swings. Those conditions make plugs either run too cool (foul) or too hot (pre-ignite) faster than many road vehicles.

Heat range matters most when duty cycle changes. Long idling, light snow work, short trips, or slow yard work cool plugs down, while sustained hard pulls, high ambient heat, towing, and wide-open runs heat them.

Quote: “The right heat range keeps the tip hot enough to self-clean, but not hot enough to cause trouble.”

Hot vs. Cold Plugs: The Core Difference

- A hotter plug fights fouling; a colder plug fights overheating. That single tradeoff explains most heat-range decisions.

- The hotter heat range keeps the firing end warmer at low speed. This helps burn off carbon and fuel deposits during idling and short-cycle operation.

- A colder heat range removes heat faster under heavy load. This reduces the risk of the plug tip becoming a hot spot during long, high-temperature operation.

6 Signs Your Spark Plug is Too Hot

A too-hot heat range shows up as heat stress at the firing end. If you see these signs, stop treating it as “just a bad plug” and address heat range, mixture, timing, and cooling.

- White or blistered insulator (instead of light tan/gray)

- Glazed deposits that look shiny or melted

- Ground strap discoloration is far back toward the threads

- Electrode wear is happening unusually fast

- Ping/knock under load that wasn’t there before

- Random misfire at high load due to unstable combustion

If you’re seeing signs of extreme heat, it’s also wise to investigate the cooling system itself. For instance, ask yourself, “Why is my coolant boiling?” as this could be a related or underlying issue.

Clear statement: “If the plug tip is becoming a hot spot, you’re flirting with pre-ignition.”

6 Signs Your Spark Plug is Too Cold

A too-cold heat range shows up as deposits and wet fouling. This is common on machines that idle a lot or never get a long, hot working cycle.

- Dry, sooty black deposits on the insulator and shell

- Wet fuel fouling after repeated cold starts

- Misfire at idle that clears when revved

- Hard starting after short shutdowns

- Strong fuel smell at the tailpipe (gas engines)

- Frequent plug replacements with the same pattern returning

It’s important to distinguish fouling from other issues. For example, the presence of oil on spark plugs points toward mechanical problems like worn piston rings or valve seals, not just a cold heat range.

Quote: “A plug that never reaches self-cleaning temperature will keep loading up.”

When to Change Heat Range

You should change the heat range only after confirming the engine is mechanically healthy and correctly tuned. Heat range is a fine adjustment, not a band-aid for low compression, a leaking injector, wrong carb jetting, or incorrect timing.

You should consider a hotter plug when the duty cycle is mostly low-load, and fouling is consistent. Examples include long idling with hydraulics off, short moves around a yard, winter warm-ups, or low-speed property maintenance.

You should consider a colder plug when the duty cycle is sustained at a high load, and you see heat signs. Examples include long hill pulls, deep mud/sand operation, continuous PTO-type loading, or hot-weather high RPM work.

Clear statement: “Fix tune and fuel first; change heat range second.”

Decoding Heat Range Numbers by Brand

Heat range numbering is not universal. A “higher number” is hotter on some brands and colder on others.

Use the manufacturer’s chart for your exact plug family. If you’re comparing options, rely on an internal cross-reference instead of guessing from the number.

To keep it simple during purchasing and troubleshooting, use an internal reference like a spark plug heat range chart for the brand you run.

Using a Heat Range Chart: A 3-Step Guide

A chart is only useful if you start from the OEM plug. Off-road engines are sensitive to the correct reach, seat type, and projected tip design.

- Start with the OEM part number (from the manual or engine tag) and match the reach/seat first.

- Cross-reference within the same plug family to move one step hotter or colder while keeping physical dimensions identical.

- Change only one step at a time and verify results after real working hours, not just a quick idle test.

Quote: “One heat-range step is an experiment; two steps is a gamble.”

How to “Read” a Spark Plug Correctly

Plug reading should be done after a representative work cycle and a clean shutdown. If you only idle in the yard and pull the plug, you’ll “diagnose” a cold-fouling problem even if the machine runs fine under load.

Focus on repeatable patterns, not one plug from one cylinder. Compare cylinders if possible, because a single oily cylinder can mimic the wrong heat range.

Treat extreme findings as a warning to inspect fueling and timing. Heat range cannot correct a lean condition, overheating cooling system, or incorrect ignition advance.

Clear statement: “Heat range can fine-tune temperature; it cannot fix a bad tune.”

7 Tips to Prevent Spark Plug Problems

Small habits prevent most heat-range headaches.

- Avoid long warm-ups at idle when possible; light load warms plugs more effectively.

- Use the correct plug gap for your ignition system and operating voltage.

- Keep air filtration tight because dust contamination accelerates deposit issues.

- Watch coolant temps and airflow since overheating can mimic a too-hot plug.

- Don’t mix plug types across cylinders on the same engine.

- Log hours and symptoms so you can see if changes truly helped.

- If you re-jet/re-tune, re-check plugs because fueling changes alter plug temperature behavior.

Final Thoughts

Spark plug heat range controls plug tip temperature, and the right range prevents both fouling (too cold) and heat damage (too hot). If you’ve verified the engine is healthy and correctly tuned, choose only a one-step heat range change and confirm it under real working conditions. When you’re ready to replace or stock spares, visit FridayParts’ product listings and choose a compatible spark plug that matches your engine’s specs and your workload.