Autumn harvest is a time-specific task, so any breakdown is unacceptable. However, the constant pressure during this period can cause the PTO shaft to wear out easily, which will decrease your working efficiency. This guide will teach you how to identify the signs of problems and how to maintain your tractor, ensuring a successful large harvest.

What is a PTO on a Tractor?

At first, knowing the fundamentals is critical. You can consider the Power Take-Off (PTO) as a power outlet to transfer your engine’s horsepower to an attached implement.

During harvest, this system powers your most critical equipment:

- Hay Balers & Rakes

- Grain Augers & Wagons

- Mowers & Forage Harvesters

- Wood Chippers for clearing land

The component that makes this all happen is the tractor PTO shaft.

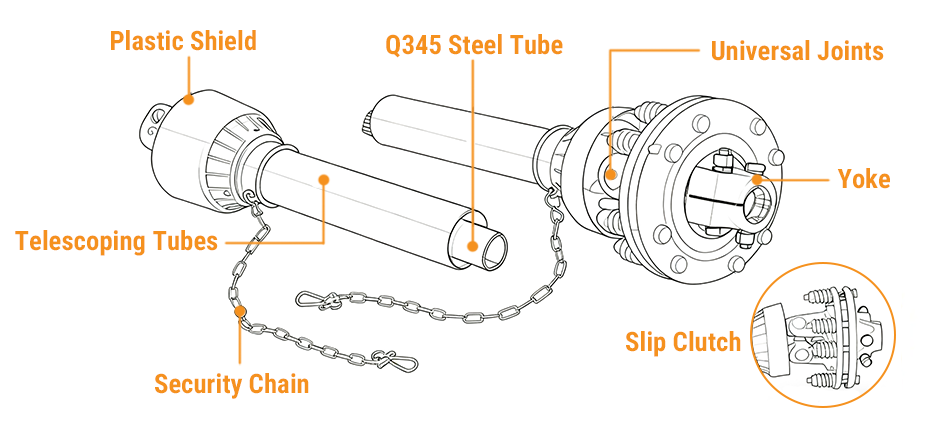

Tractor PTO Shaft Diagram

Understanding the individual components is the first step to a quick diagnosis. When you inspect your shaft, here’s what you’re looking at:

- Yokes: The “jaws” at each end that connect to the tractor and the implement.

- Universal Joints (U-Joints): The cross-and-bearing “knuckles” inside the yokes that allow the shaft to flex and transmit power at an angle. This is the most common failure point.

- Telescoping Tubes: The inner and outer tubes slide, allowing the shaft to change length as the tractor moves over uneven ground.

- Safety Shields: The plastic cones and tubes that cover the entire rotating assembly. They are not optional; they are essential for your safety.

- Shear Bolt / Slip Clutch: A built-in safety mechanism designed to fail (break or slip) if the implement gets jammed, protecting your tractor’s expensive gearbox.

How to Identify Bad Symptoms of the PTO Shaft

A worn-out PTO shaft rarely fails without warning. These signs are your tractor’s way of telling you it needs attention—act on them immediately to prevent a full-blown breakdown.

Warning Sign #1: Destructive Vibrations

What it feels like: A new or worsening vibration through the tractor floor or seat when the PTO is engaged.

What it means: This is a serious red flag. Vibration under load means something is out of balance and is actively destroying itself.

- Likely Cause: A failed bearing cap in a U-joint, a bent shaft tube, or excessive wear in the telescoping tubes.

Warning Sign #2: Alarming Noises

What it sounds like: Any new noise is a bad noise. Listen for:

- Clunking or Banging: Especially when engaging the PTO or changing load. This points to worn-out U-joints or loose yokes.

- Squealing or Grinding: This is the sound of metal-on-metal destruction. It’s a cry for grease from a U-joint that is moments away from complete failure.

- Rattling: Often caused by a loose or broken safety shield. This is a major safety hazard that must be fixed immediately.

Warning Sign #3: Visible Damage & Wear

What it looks like: A quick visual check can tell you everything.

- Cracked or Missing Shields: An unguarded, spinning shaft is one of the most dangerous things on a farm.

- Bent Tubes or Dented Shields: A sign of impact that could have caused unseen damage to the shaft itself.

- Excessive Rust: Especially around the U-joints, which can cause them to seize and fail.

- Leaking Grease: Black, greasy streaks slung around the U-joint indicate a failed seal.

How to Check Your Pre-Harvest PTO Health

Before the harvest rush begins, perform this quick inspection. It could save you days of downtime.

SAFETY FIRST: Before you touch anything, turn off the tractor, remove the key, and ensure the PTO is disengaged.

- The Wiggle Test: Firmly grab the shaft near each U-joint. Try to wiggle it up-and-down and side-to-side. There should be almost zero play. If you feel looseness or a “clunk,” the U-joint is worn.

- The Rotation Test: Gently twist the shaft. There should be very little rotational slack.

- Spin the Shields: The outer safety shields should spin freely by hand. If they are stuck to the shaft, they are not working correctly and are a serious hazard.

- Inspect the U-Joints: Look for signs of rust, leaking grease, or any visible cracks in the yokes.

- Check the Locking Pins: Ensure the pins or collars that lock the shaft to the tractor and implement are working correctly and are not damaged.

Find the Right PTO Parts at FridayParts

When your inspection reveals a problem, a timely repair is the most cost-effective solution. Waiting for a complete failure can cause a chain reaction, damaging the gearbox on your tractor or implement—turning a small repair into a massive expense.

At FridayParts, we make it easy to find exactly what you need. Use this chart to match the symptom to the solution:

| The Problem | The Cause | The Part |

|---|---|---|

| Vibration, Clunking, Squealing | Worn or failed Universal Joint | Deck Drive Female PTO Half Shaft U-Joint Coupler 398914 |

| Cracked, Broken, or Missing Guard | Impact or age-related failure | 1-3/8″ 6 Spline End T1 20″-24″ Yellow PTO Drive Shaft for Tractor |

| The shaft is Bent or Severely Rusted | Impact damage or long-term wear | PTO Shaft AH220096 AH155077 AH154737 AH141283 |

| Shaft Won’t Lock On | Damaged locking pin or yoke | PTO Shaft Extension with Quick Release 1-3/8″ 6 Spline Female & Male |

| PTO Sheared on Jammed Implement | The shear bolt did its job | 1-3/8″ 6 Spline Ends Slip Clutch for PTO Shaft |

We supply high-quality parts for all major brands, whether you run a John Deere, Kubota, Ford, or other make of tractor. This table is just one option; if you’d like to explore more, please visit our one-stop online shop.

Final Thoughts

Your tractor’s PTO shaft is a lifeline to your productivity during the harvest season. Regularly inspecting and maintaining it is one of the most cost-effective ways to make sure your investment.

Don’t let a predictable failure waste your time.

Ready to ensure your tractor is 100% ready for harvest? Explore our complete collection of Tractor PTO Shafts and Components at FridayParts.com and get the parts you need delivered fast.

Take care of your equipment today, and it will take care of you all season long.