Hydraulic leaks in excavators—and heavy equipment in general—are a common yet frustrating problem. A leaking hydraulic system leads to reduced performance, increased maintenance costs, and even safety hazards. But the good news? Most hydraulic leaks have clear causes, and knowing these can help you prevent future breakdowns.

There are different types of hydraulic leaks, and locating them requires a systematic approach. You might wonder, how do you find the source of a leak? We’ll walk you through the detection process, then give you a step-by-step guide to fixing hydraulic leaks in your excavator.

This guide covers everything you need to know—from identifying symptoms to repairing damaged hoses. While the solutions apply to various heavy machinery, we’ll focus on excavators as an example. Stick around for our FAQ section at the end, where we answer the most common questions about hydraulic leaks.

What are Hydraulic Leaks in Excavators?

Before we can actually address the problem, let’s first understand what hydraulic leaks are. Hydraulic leaks in excavators occur when the hydraulic fluid escapes from its designated system, leading to reduced performance and efficiency. These leaks disrupt the machine’s operation, potentially causing further damage if left unchecked. The hydraulic leaks are common challenges for excavator owners, particularly when dealing with older or heavily used equipment.

Common Causes of Hydraulic Leaks in Excavators

Hydraulic leaks don’t happen randomly. They usually result from specific issues. Here are the most common causes:

Contamination in the System: Dirt or debris can erode parts, leading to leaks.

High Pressure or Temperature Conditions: Stress from extreme operations can compromise system integrity. Though the hydraulic leaks show no seasonal breakout, in the summer, the high temperature could trigger the hydraulic oil to expand, thus increasing the risk of leakage.

Aging Seals and O-rings: Natural wear and tear lead to cracks and gaps. During the rainy season, contaminants are more likely to seep into the hydraulic system through aged seals or damaged components.

Improperly Tightened Connections: Loose fittings allow fluid to escape.

Damaged Hydraulic Hoses: Abrasion, punctures, or prolonged use can weaken hoses.

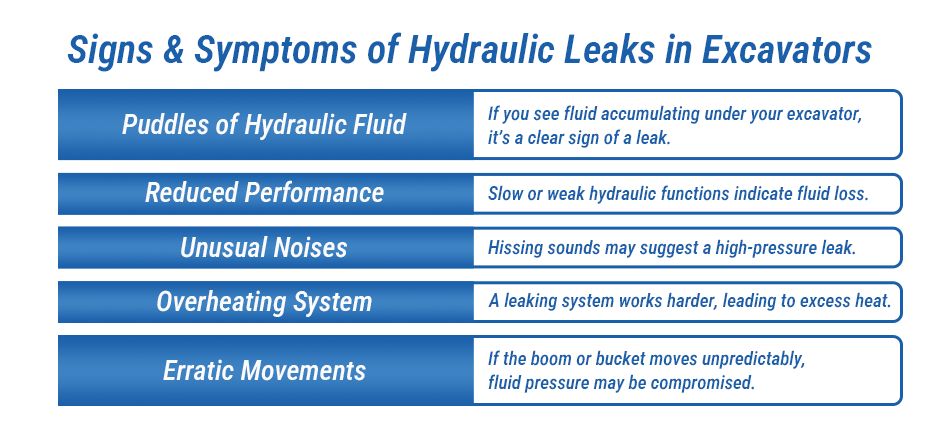

Spotting hydraulic leaks early is critical for maintaining excavator performance. Here are the key signs to watch for:

- Puddles of Hydraulic Fluid: If you see fluid accumulating under your excavator, it’s a clear sign of a leak.

- Reduced Performance: Slow or weak hydraulic functions indicate fluid loss.

- Unusual Noises: Hissing sounds may suggest a high-pressure leak.

- Overheating System: A leaking system works harder, leading to excess heat.

- Erratic Movements: If the boom or bucket moves unpredictably, fluid pressure may be compromised.

How to Locate Hydraulic Leaks?

Before you can fix the problem, you should get to know where the problem lies first. Finding a hydraulic leak requires patience and attention to detail. Here are the steps to follow:

- Perform a Visual Inspection: Look for oil stains, wet spots, or drips around hoses, fittings, and cylinders.

- Check Hydraulic Fluid Levels: A sudden drop in fluid levels usually indicates a leak.

- Use a Piece of Cardboard or Paper: Hold it near suspected leak points—if oil sprays onto it, you’ve found the leak.

- Listen for Hissing Sounds: A pressurized leak often produces a distinct hissing noise.

- Use a Leak Detection Fluid: Special UV dyes can help identify leaks under blacklight.

- Inspect Hoses and Seals Closely: Even minor cracks or loose connections can be a problem.

Never use your bare hands to check for leaks—high-pressure hydraulic fluid can penetrate the skin, causing serious injury.

How to Fix Hydraulic Leaks in an Excavator? Step-by-step Guide!

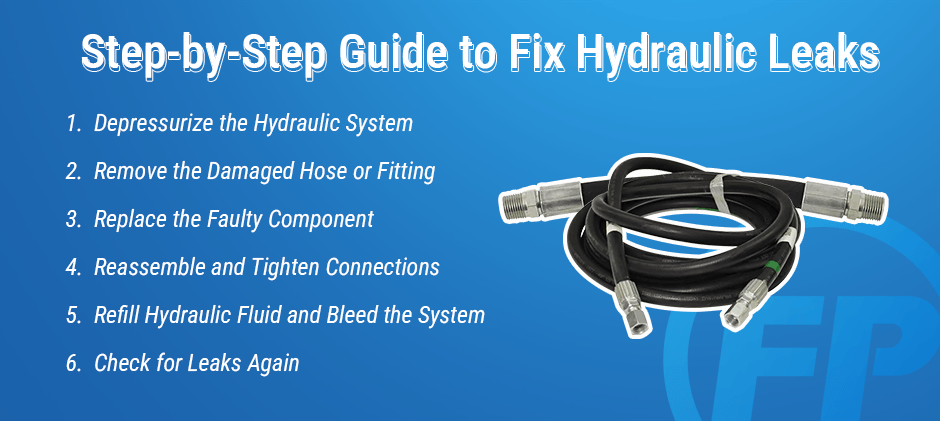

Once you’ve located the leak, follow these steps to fix it properly.

- Depressurize the Hydraulic System

First, turn off the excavator and make sure the hydraulic system is completely depressurized. This step is crucial to prevent accidental fluid ejection, which can cause serious injury. Slowly loosen the hydraulic reservoir cap to release any trapped pressure inside the system.

- Remove the Damaged Hose or Fitting

Next, use the appropriate wrenches to carefully disconnect the leaking hose or fitting. Take your time to avoid damaging surrounding components. Once removed, inspect the part closely for cracks, worn seals, or stripped threads that could have caused the leak.

- Replace the Faulty Component

After identifying the problem, install a new hose, fitting, or seal that matches your excavator’s specifications. Ensure that you are using high-quality replacement parts, as this will improve the durability and reliability of your hydraulic system.

- Reassemble and Tighten Connections

Now, reconnect all fittings and clamps securely, but be cautious not to overtighten them, as this can cause new leaks. If required, apply a suitable thread sealant to enhance the connection’s integrity and prevent further leakage.

- Refill Hydraulic Fluid and Bleed the System

Once everything is in place, add the correct hydraulic fluid to the reservoir until it reaches the recommended level. Then, cycle the hydraulic controls several times to remove any trapped air from the system, ensuring smooth operation.

- Check for Leaks Again

Finally, start the excavator and carefully monitor the repaired area for any signs of new leaks. If everything appears to be functioning properly without leaks, your repair is successful, and the machine is ready for operation.

Hydraulic Leaks in Excavator FAQs

How Much Does It Cost to Fix a Leaking Hydraulic Cylinder?

- Small repairs (seal replacements) cost $100-$300.

- Full cylinder replacements can range from $500-$1,500.

But If you decide to DIY and come to FridayParts for hydraulic parts, you can save a brunch of money. We sell and only sell parts that meet OEM standards, and we offer cost-effective solutions!

How to Add Hydraulic Fluid to Excavator?

Please read: How to Add Hydraulic Fluid to Excavator (Beginner Recommended)

Why Does My Hydraulic Fitting Keep Leaking?

A hydraulic fitting may continue to leak due to several reasons, including improper installation, worn-out seals, or excessive pressure within the system. If the fitting is not tightened correctly, it can create gaps that allow fluid to escape. Over time, seals and O-rings inside the fitting may degrade, leading to persistent leaks. Additionally, fluctuations in hydraulic pressure can put extra strain on the fitting, causing it to loosen or develop cracks. To prevent leaks, ensure that fittings are properly installed, use high-quality seals, and regularly check for signs of wear or pressure inconsistencies.

Conclusion

Hydraulic leaks in excavators are a major nuisance, but they don’t have to be a costly disaster. By understanding the causes, recognizing symptoms early, and following a structured repair process, you can keep your excavator in top condition.

At FridayParts, we care about the health of your equipment. We offer aftermarket excavator parts and top-notch customer support for your needs. We understand how important it is to choose the right and quality parts for your excavator, so all the parts are selected to meet OEM standards. Our commitment to professionalism means every excavator part we provide is built to deliver reliable performance.

Regular maintenance, using high-quality parts, and checking for leaks before they become major issues will save you both time and money. You can subscribe to FridayParts YouTube channel or follow FridayParts blog for more useful information!