Has your excavator or loader experienced an overheating shutdown recently? This may be a problem with your equipment’s cooling system. Don’t worry, this situation often occurs in the use of heavy equipment. Based on past experience, it is mostly a problem with your engine’s cooling fan or radiator. You only need to check the problem and replace the parts in time to solve it. This article will help you understand one of the common problems in the heavy equipment cooling system – the damage to the cooling fan. I will help you spot cooling failures in your equipment and guide you on replacing parts.

4 Signs Your Cooling Fan Isn’t Working Properly

Cooling fans play a vital role in keeping equipment or engines at safe operating temperatures. When it starts to fail, overheating becomes a serious risk, which can reduce performance and lead to expensive repairs, so identifying early warning of a malfunctioning industrial cooling fan or off-road equipment fan is key.

1. Overheating Engine or Equipment

The most obvious sign of an overheated engine is that you may notice a higher-than-normal temperature gauge on your dashboard. In severe cases, steam may escape from under the hood, or you may smell a distinct coolant odor. These symptoms indicate that the cooling system is struggling to regulate the heat, usually due to a malfunctioning fan. When a cooling fan fails, airflow is reduced, causing higher temperatures and possibly damage to components such as the head gasket or piston rings.

2. Unusual Noises from the Cooling Fan

A faulty cooling fan often makes abnormal noises, which is also a warning sign. You can usually tell by whether there are the following sounds: Whirring or Grinding (Often indicates failing bearings in the fan motor or fan clutch), Clicking or Rattling (Could be loose cooling fan blades or debris hitting the fan), Loud Roaring (A fan clutch stuck in the engaged position can cause excessive noise and strain). If you hear your cooling fan making strange noises, have it checked immediately. Prolonged use of a noisy fan can cause further damage, reduce the efficiency of your cooling system, and increase the risk of overheating.

3. Reduced Cooling Efficiency

A failing cooling fan significantly impacts the overall efficiency of your cooling system. When the fan cannot maintain proper airflow, the system struggles to dissipate heat effectively. This inefficient cooling becomes more apparent in high-demand situations, such as when you need to operate your device in high temperatures or harsh environments. Addressing reduced cooling efficiency promptly can prevent further strain on your equipment.

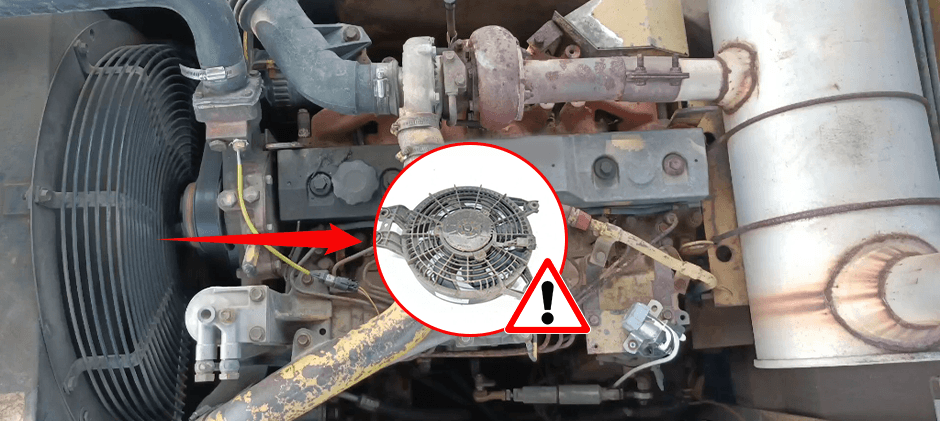

4. Visible Damage to Cooling Fan Blades

Damage to the cooling fan blades is the most obvious symptom of a problem that can be seen with the naked eye. You can easily see cracks or incomplete blades during inspection. They are usually caused by hard gravel or dirt. Of course, long-term improper use, such as improper installation or long-term wear, can also damage the fan. Therefore, please check your cooling blades regularly to prevent more serious problems such as radiator or thermostat overload damage.

Can I Drive It with a Broken Engine Fan?

You had better not do that. It is very dangerous to continue to use the machine with a damaged engine fan. Continuing to run your engine without adequate cooling will soon lead to more trouble, such as overheating of the engine, which can cause the cylinder head to deform and the engine to seize. Overheating can also cause damage to seals, hoses, and electrical components in the engine compartment. These problems can only be repaired at great expense, so if you suspect your fan is faulty, do not ignore it; stop using the machine as soon as it is safe to do so and have it inspected.

When Should the Engine Cooling Fan be Replaced?

An engine cooling fan or its associated parts (like the fan clutch or fan motor) should be replaced when:

- Confirmed Failure: Any of the symptoms mentioned above are diagnosed as a fan-related problem.

- Visible Damage: Cooling fan blades are cracked, broken, or significantly bent.

- Faulty Fan Clutch: The clutch is leaking, not engaging/disengaging correctly, or has excessive bearing play.

- Failed Fan Motor: The electric motor is burned out, has worn bearings, or operates intermittently.

- Preventative Maintenance (Less Common): In some critical applications or based on manufacturer recommendations for high-hour machines, a fan might be replaced proactively, though typically it’s replaced upon failure or clear signs of wear.

- During Related Repairs: If you’re already working on the cooling system (e.g., replacing a radiator or water pump) and the fan shows signs of age or wear, it might be cost-effective to replace it simultaneously.

It is usually more cost-effective to replace a part than to replace the entire equipment. You can easily find all the parts you need to replace your cooling system on the FridayParts official website without spending a lot of time. At the same time, you can easily compare products of different brands and prices on FridayParts. This can save more time and money on your repair matters.

How to Replace the Cooling Fan of Your Device?

The difficulty of replacing a heavy equipment cooling fan depends on the type of equipment you have. Please be sure to consult the equipment’s maintenance manual before replacing the equipment to avoid incorrect parts removal.

Step 1. Remove Old Fan

Mechanical Fans (with clutch): You may need a special tool to hold the pulley while loosening the fan clutch nut or bolts. Sometimes the fan and clutch are removed as one unit.

Electric Fans: Disconnect the electrical connector. Unbolt the fan motor or the entire cooling fan assembly from its mounting points.

Hydraulic Fans: Safely relieve any hydraulic pressure, then disconnect hydraulic lines (cap them to prevent contamination) and unbolt the fan motor/assembly.

Step 2. Install the New Fan

Mount the new cooling fan assembly, fan motor, or fan clutch in reverse order of removal.

Ensure cooling fan blades are oriented correctly for proper airflow.

Tighten all bolts and connections to the manufacturer’s specified torque.

Reconnect: Reattach electrical connectors, hydraulic lines, or belts as applicable.

Reinstall Other Components: Put back any shrouds or guards that were removed.

Finally, Test: Reconnect the battery. Start the engine and let it reach operating temperature. Observe the new fan’s operation. Check for proper engagement (clutch fans), smooth running, and ensure the engine maintains a normal temperature. Check for any leaks if the hydraulic lines were disconnected.

Replace Cooling Fans with FridayParts

A fully functional cooling fan is essential for the health and longevity of your off-road equipment. Don’t let a failing fan lead to overheating and expensive repairs. Recognizing the symptoms early allows for timely replacement.

At FridayParts, we specialize in providing high-quality aftermarket cooling fans and cooling system components for a wide range of heavy equipment brands. Our vast inventory ensures you can find the right cooling fan assembly, fan motor, or fan clutch at affordable prices. We are committed to helping you keep your machinery running efficiently. Visit Fridayparts today to find the durable replacement parts you need!