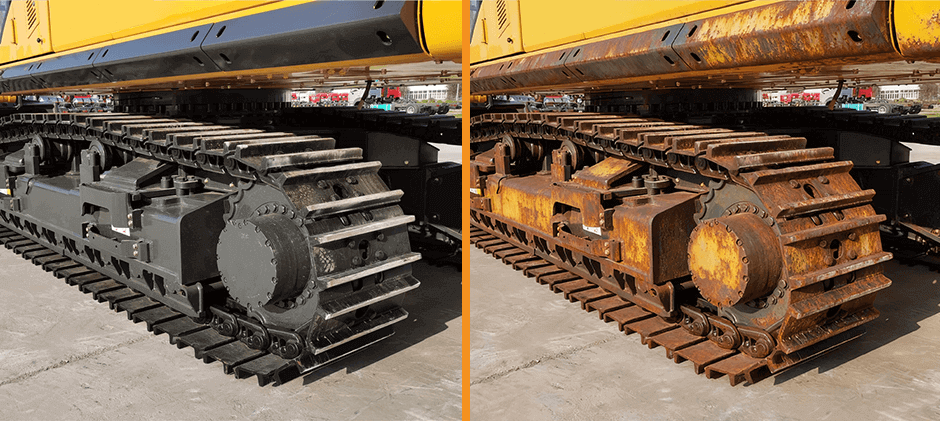

Undercarriage rust is an issue confronted by all tracked machinery. A rusted undercarriage not only appears unsightly but also undermines structural integrity, accelerates the wear of costly components, and may even precipitate the cessation of powerful machines. Undercarriage corrosion cannot be remedied in a one-time manner; it constitutes a process of continuous maintenance. This guide shall analyze the principal causes of undercarriage rust and provide eight practical and efficacious techniques to safeguard your investment, prolong the service life of your equipment, and ensure the smooth operation of your enterprise.

What Causes Undercarriage Rust?

Undercarriage corrosion arises from an electrochemical phenomenon known as oxidation, which occurs when steel is exposed to both oxygen and moisture. On construction sites, numerous peculiar environmental factors about the undercarriage substantially accelerate this process.

- Moisture and debris accumulation: The intricate architecture of the undercarriage — encompassing rollers, idlers, track chains, and guards — creates numerous cavities where mud, grime, and water stubbornly lodge. Such entrapped substances tenaciously retain moisture against the metallic surface for prolonged durations, thus cultivating an ideal breeding ground for rust formation.

- Abrasive surroundings: Throughout each operational hour, the undercarriage incessantly engages in friction with rocks, sand, gravel, and other abrasive particulates. This perpetual abrasion resembles the act of sanding, relentlessly stripping away the protective paint and coatings. Once the bare metal stands exposed, oxidation proceeds almost instantaneously.

- Chemical and Soil Corrosion: A construction site is by no means a benign environment. Your excavator may labor upon acidic soil, in regions laden with salinity — such as coastal zones or winter work areas utilizing de-icing salts — or encounter accidental chemical leakage. These corrosive agents inflict damage upon metal far more aggressively than mere aqueous exposure.

- Lack of Maintenance: To put it plainly, negligence is the true culprit of rust. Irregular cleaning of the undercarriage, indifference toward paint scratches, and the absence of routine inspection collectively permit minor surface oxidation to evolve into profound structural corrosion, ultimately compromising essential components.

How to Protect the Undercarriage from Rust?

Maintaining a rust-free excavator undercarriage in frequent use and harsh environments requires specific maintenance techniques. Here are eight practical tips to help you avoid rust on your excavator undercarriage.

1. Implement a Strict Cleaning Routine

This stands as the most efficacious strategy against rust. A clean undercarriage system is, by nature, a dry undercarriage system.

- End-of-Day Clean-Out: Upon concluding each working day, it is essential to clean the undercarriage system, particularly after operations conducted on moist or muddy road surfaces. Utilize a shovel or scraper to remove large masses of mud and debris around the track frame, carrier rollers, and atop the track plates.

- Pressure Washing: Following manual cleansing, employ a high-pressure washer for thorough rinsing. Pay particular attention to the final drive motor, front idler, and the areas surrounding both upper and lower rollers. A meticulous washing may eliminate coarse, moisture-retaining grime films that scraping alone cannot expel.

2. Use Proper Storage Practices

The manner and position in which the machine is stationed overnight or for extended periods exert a profound influence upon storage outcomes.

- Park on Dry, Elevated Surfaces: Avoid placing the excavator directly upon soil or within puddles. Whenever feasible, position it upon concrete blocks, gravel, or wooden planks. This allows air to circulate beneath the machine, facilitating complete dryness and preventing ground moisture from permeating the undercarriage.

- Covered Storage: If the machine remains idle for an extended period, it is advisable to store it indoors or under a covered structure. Such shelter shields the equipment from rain, snow, and morning dew — the principal agents that instigate rust formation.

3. Conduct Frequent Visual Inspections

The early discovery of rust marks constitutes the key to halting its propagation. Operators must be instructed to incorporate this into their daily inspection routine.

- Look for Tell-Tale Signs: Scrutinize the track frame, roller brackets, and idler forks for paint blistering, orange discolorations, or peeling metal. These phenomena signify the earliest manifestations of corrosion beneath the surface.

- Check for Packed Debris: Even during arid conditions, examine the areas surrounding the rollers for accumulated debris. Hardened, desiccated dirt yet retains ambient moisture and, over time, may evolve into a source of corrosion.

4. Maintain Protective Coatings

The paint upon the undercarriage serves as its foremost line of defense.

- Touch Up Scratches Immediately: Should any scratch or chip expose the bare metal, the area must be cleansed without delay and a coat of touch-up paint applied. A can of anti-rust primer and a topcoat of matching hue—though a modest investment—yields abundant returns.

- Consider Specialized Undercoaters: For machinery laboring in environments of extreme corrosiveness, the employment of heavy-duty rubberized or wax-based primers may be contemplated. Such products render a thick, resilient layer of protection, exhibiting greater resistance to abrasion than ordinary paint.

5. Apply Rust Inhibitors

For prolonged storage or instances requiring enhanced protection, rust inhibitors prove exceedingly efficacious.

- Use Fogging Oils or Waxy Films: These substances are contrived to infiltrate narrow crevices—such as between track pins and bushings—while expelling moisture. They deposit a thin, self-healing membrane that shields the metal from the intrusion of oxygen.

- Off-Season Application: Before winter storage, coating the entire undercarriage system with rust preventive constitutes an excellent practice, particularly under humid or snowy climatic conditions.

6. Practice Smart Operating Techniques

The manner in which the operator commands the machine bears direct influence upon the wear rate of the undercarriage system and the erosion of its coating.

- Minimize reverse spinning: Sharp turns upon hard and coarse surfaces—such as concrete or rock—abrade the track shoes and roller flanges, stripping the paint and hastening wear. Operators should be encouraged to perform broader, smoother turns.

- Reduce needless travel: An excavator is an implement of excavation, not propulsion. Limit long-distance traversing, for every revolution of the track contributes to wear. Whenever feasible, employ alternate machinery for extensive material transport.

7. Manage Corrosive Environments

When avoidance of corrosive workplaces proves impossible, heightened vigilance becomes indispensable.

- Frequent Rinsing: In locales of saline or acidic nature, repeated washing of the undercarriage with clear water throughout the day assists in neutralizing corrosive agents, thereby forestalling damage.

- Comprehension of Soil Composition: Acquaint oneself with the constitution of the site’s soil. In industrial areas or particular agricultural zones, the soil may possess strong corrosiveness, necessitating more frequent and thorough cleansing.

8. Replace Worn Components Promptly

At times, the presence of rust portends the imminent end of a component’s service life.

Don’t Run to Failure: When rollers seize or the track chain extends beyond its threshold, collateral damage may be inflicted upon other constituents of the undercarriage system. Once rusting and wear become pronounced, the structural integrity of the component is forfeited, rendering repair neither safe nor economical. Procuring high-quality aftermarket undercarriage parts stands as the most prudent recourse to restore performance and forestall further detriment.

The Impact of Rust on Excavators

Ignoring undercarriage rust has serious consequences that go far beyond appearance. It directly affects your machine’s safety, performance, and value.

- Compromised Structural Integrity: This is the most dangerous impact. Rust eats away at the steel, weakening critical components. A severely rusted track frame can crack under load, and rusted roller flanges can break off, potentially causing the track to de-track and leading to a dangerous loss of stability.

- Reduced Performance and Efficiency: Rust creates friction. A rusty and stiff track chain requires more power from the final drives to move, increasing fuel consumption. Seized rollers or idlers don’t turn freely, causing them to develop flat spots and rapidly wear down the track links.

- Decreased Resale Value: A rusty undercarriage is one of the biggest red flags for a potential buyer. It signals a history of poor maintenance and hints at other hidden problems. A clean, well-maintained undercarriage can add thousands of dollars to the resale value of a used excavator.

Protect Your Excavator Undercarriage

The undercarriage system serves as the fundamental cornerstone upon which the excavator performs its terrestrial labors. Safeguarding this foundation against the relentless menace of rust is of paramount significance. Through the persistent execution of cleansing, meticulous inspection, and the deployment of sagacious protective measures, corrosion may be effectively restrained. When the march of wear renders replacement inevitable, the selection of high-quality yet reasonably priced aftermarket parts from FridayParts shall ensure that your machine remains a steadfast and invaluable asset for many years to come.