A stuck oil filter is common on off-road machines because heat, mud, vibration, and overtightening lock it in place. The safest fix is to use the least aggressive method first and step up only when needed. This guide demonstrates how to resolve stuck oil filter issues using simple tools, clear steps, and “last resort” options that minimize damage to the filter mount and engine.

When Should You Stop and Let the Engine Cool?

You should work on a cool engine to avoid burns and ensure safety. While some believe a warm engine can make loosening easier due to metal expansion, the risk of severe burns from hot exhaust, engine components, and oil far outweighs any potential benefit. Safety must always be the top priority. Hot exhaust pipes, hot oil, and tight spaces on UTVs/tractors/skid steers make injuries easy.

You should stop if you see fuel, electrical damage, or a cracked filter mount. A stuck filter is annoying, but breaking the mount can turn a quick oil change into a major repair.

“A stuck filter is cheaper than a broken housing—slow down before you force it.”

Why Does an Oil Filter Get Stuck?

Most filters get stuck because of overtightening and heat cycles. The rubber gasket hardens, then “glues” itself to the engine over time.

Some filters get stuck because of dirt and corrosion. Mud and water can rust the can or seize threads, especially on machines stored outdoors.

Some filters get stuck because the old gasket stayed on the engine. This ‘double gasket’ situation not only makes removal difficult but creates a severe risk of catastrophic oil leaks, which can lead to low oil pressure in an engine. A double gasket can squeeze and bind so tightly that removal is tough.

Tools You Need to Remove a Stuck Oil Filter

The right tool gives grip without crushing the filter, and knowing how to choose the correct oil filter wrench is key. Better grip usually beats more strength.

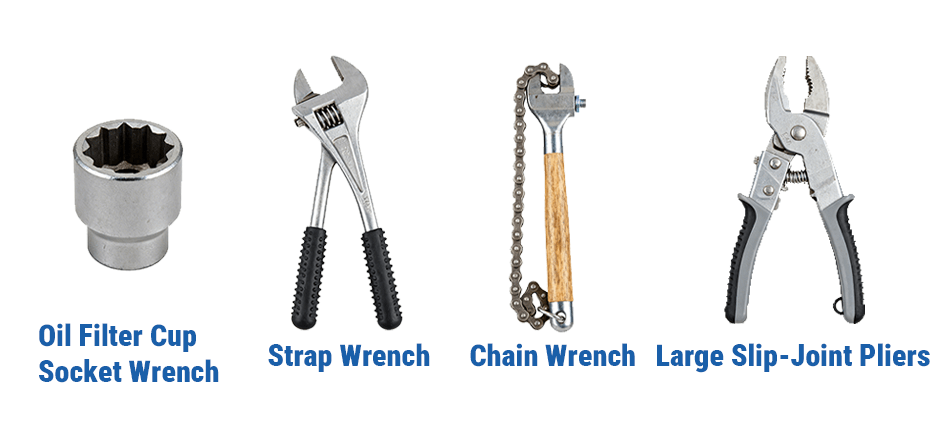

These tools are the most useful (in order):

- Oil filter cup/socket wrench (best when you have space and the correct size)

- Strap wrench (good all-around, less likely to puncture)

- Chain wrench (very strong, more likely to crush the can)

- Large slip-joint pliers (works but can deform the filter quickly)

- Pick/scraper for cleaning the mounting face and checking the gasket

A drain pan and rags are not optional. Once it breaks loose, oil will spill fast.

Things to Prepare before You Turn on the Filter

You should clean the area first so you can see what you’re doing. Dirt around the base can hide a double gasket or a cracked seal.

You should confirm the direction before you pull hard. Most filters loosen counterclockwise when viewed from the end of the filter, but tight access can flip your perspective.

You should protect nearby hoses and wiring. Tools slipping on an off-road machine can cut a coolant hose or tear a sensor plug.

7 Steps Guide to Remove a Stuck Oil Filter

You should start gently and increase the force step by step. This process is a crucial part of knowing when and how to change your engine oil filter, as it reduces the chance of crushing the filter or damaging the adapter.

- Grip at the base, not the middle. The base is stronger and less likely to collapse.

- Try a cup/socket filter wrench first. A correctly fitting cup gives the most controlled torque.

- Tap the filter base lightly. Small taps around the rim can break the gasket’s “bond.”

- Try a strap wrench and keep it tight. A loose strap slips and polishes the can smoothly.

- Turn in short moves, then reset. Small controlled turns beat one huge yank in tight spaces.

- If it won’t move, tighten it a hair first. A tiny clockwise bump can crack the seal loose.

- Remove by hand once it breaks free. Hand removal helps you feel if the threads are binding.

“Control beats power—most damage happens when the tool slips.”

5 “Last Resort” Methods

You should use last-resort methods only after normal tools fail. These methods can be messy and can damage parts if done carelessly.

1) Use a chain wrench (strongest grip)

A chain wrench works when the filter canister is already deforming. It can crush the filter, so keep it close to the base.

2) Use large pliers at the base

Pliers can break it loose when a strap keeps slipping. They often dent the can, so plan to replace the filter (you already are).

3) Add grip with sandpaper or a rubber sheet

Extra friction can stop the tool from slipping. Wrap the filter to help a strap wrench bite.

4) Warm the mount slightly (not the filter)

A little warmth can expand the metal mount and loosen the threads. Use caution around fuel lines and plastics, and do not use open flame.

5) Screwdriver-through-the-filter (true last resort)

A screwdriver method is risky because it can tear the can and still not turn the base. Only do this if you can safely clean the mess and you have good access to avoid stabbing nearby parts.

“If you punch the can, you’re committed—make sure you can still turn the base.”

How to Handle a Filter that Comes Apart?

You must remove the threaded base ring if the can rips off. The base ring can stay stuck to the engine and looks like part of the mount.

You should use a chisel/punch carefully on the base ring. Tap the ring counterclockwise in small steps to avoid gouging the sealing surface.

You must check for a stuck gasket. A leftover rubber gasket can cause leaks even with a new filter.

What Should You Check before Installing the New Filter?

You should inspect the sealing surface and threads before you install anything. A small nick on the sealing face can create a slow leak that shows up only under load.

You should confirm that the old gasket is removed. A clean, bare metal mounting face is the goal.

You should pre-lube the new gasket with clean oil. A thin oil film prevents the gasket from binding next time.

How Tightly Should You Install the New Oil Filter?

You should tighten most spin-on filters by hand, not with a wrench. A common rule is “hand tight, then 3/4 turn,” but always follow the machine or filter instructions.

You should mark the filter with a line if space is tight. A simple marker line helps you measure the turn when you can’t see well.

“Overtight is the #1 reason the next oil change turns into a fight.”

6 Tips to Prevent a Stuck Oil Filter

Good habits make the next removal easy. Prevention is cheaper than broken housing and wasted time.

- Oil the gasket before installation.

- Hand-tighten only (unless the manual says otherwise).

- Clean mud and salt off the area after rides or jobs.

- Replace the filter on schedule, not “whenever.”

- Use the correct filter size and thread.

- Check for leaks after the first start, then re-check after a short run.

Summary

Removing a stuck oil filter is safest when you start with the right wrench, work on a cool engine, and step up methods slowly. Clean the mounting face, confirm the old gasket is gone, and install the new filter hand-tight to prevent future seizures. When you’re ready to finish the job, you can find a matching replacement oil filter on FridayParts to get your machine back to work with a clean, leak-free oil change.