What is a solenoid valve? A solenoid valve is an electromechanical device that controls the flow of liquid or gas using an electric current. These parts are widely used in industrial automation, HVAC systems, irrigation, automotive transmissions, and even household appliances. Over time, solenoid valves can deteriorate due to wear, contamination, or electrical failures. This guide covers everything you need to know about solenoid valve replacement, from bad solenoid symptoms to a step-by-step replacement guide. The replacement process involves diagnosing the problem, turning off power and fluid sources, carefully removing the old valve, installing a new one securely, and conducting a test to ensure proper functionality. Scroll the article to discover more details and facts!

More reads: How Does a Hydraulic Solenoid Valve Work? Troubleshooting, Function & Selection Guide

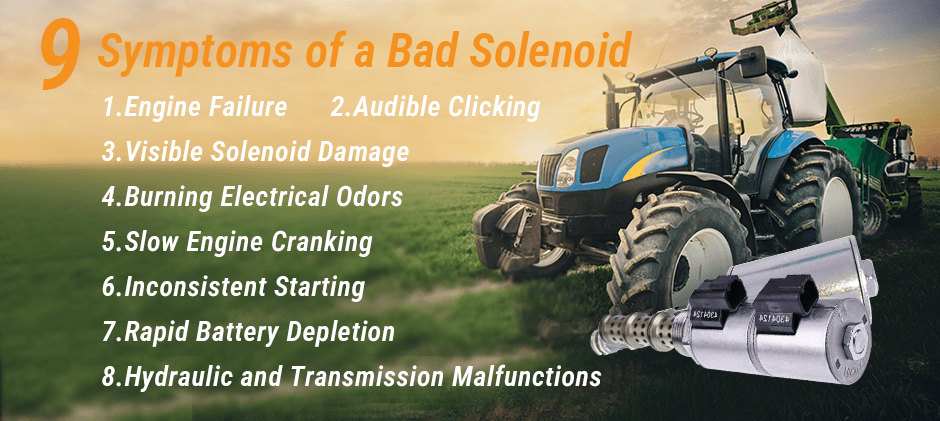

When to Replace a Solenoid Valve? 9 Symptoms of a Bad Solenoid

- Audible Clicking: Solenoid Engagement Failure in Heavy Machinery

A single click indicates the solenoid attempts to engage but lacks sufficient power; rapid clicking suggests a battery issue.

- Visible Solenoid Damage: Cracks and Burn Marks on Heavy Equipment

Inspect for physical damage, including cracks, burn marks, or corrosion, indicating a faulty solenoid.

- Burning Electrical Odors: Solenoid Overheating in Heavy-Duty Machines

A burning smell after attempting to start points to potential solenoid or wiring damage, requiring differentiation from hydraulic fluid odors.

- Slow Engine Cranking: Insufficient Power Delivery in Heavy Equipment

The engine cranks slowly and weakly, indicating inadequate power from the solenoid to the starter motor.

- Inconsistent Starting: Intermittent Solenoid Function in Heavy Machinery

The equipment starts intermittently, suggesting a failing or inconsistent solenoid, possibly due to vibration-induced connection issues.

- Rapid Battery Depletion: Parasitic Draw from Faulty Solenoids

The battery drains quickly, even when the equipment is off, indicating a solenoid that fails to disengage.

- Hydraulic and Transmission Malfunctions: Solenoid-Controlled System Failures

Hydraulic systems exhibit slow or erratic movement, and transmissions experience shifting difficulties due to faulty solenoid valves.

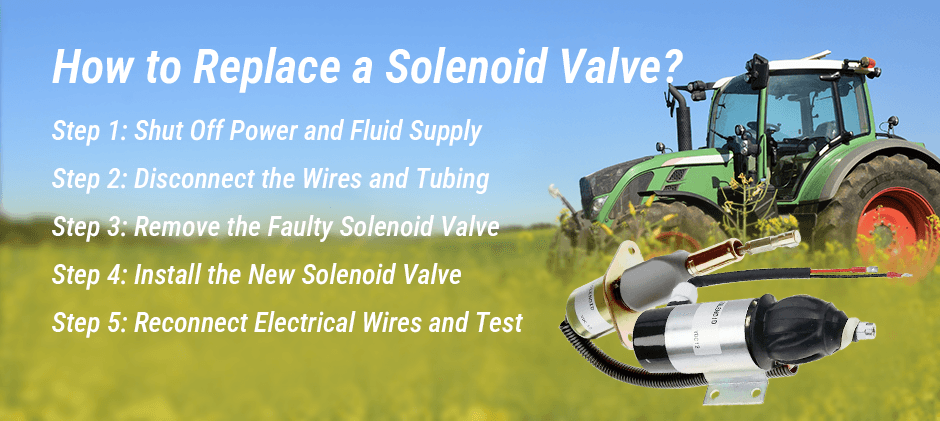

Step-by-Step Process to Replace a Solenoid Valve

Tools and Materials Required

To complete the replacement, you’ll need a new solenoid valve that matches your system’s specifications. Here is what you need:

- New solenoid valve (compatible with your system)

- Adjustable wrench or pliers

- Screwdriver

- Pipe tape or thread sealant

- Multimeter (for electrical testing)

- Safety gloves and goggles

Step 1: Shut Off Power and Fluid Supply

Before starting the replacement process, it’s essential to turn off the power and shut off the fluid or gas supply to prevent any hazardous leaks or electrical shocks. Ensure that the system is fully depressurized before proceeding.

Step 2: Disconnect the Wires and Tubing

Carefully disconnect any electrical wiring connected to the solenoid valve. It’s helpful to take a picture of the wiring setup before removal to ensure correct reinstallation. Use a wrench to loosen the valve’s connections and detach the tubing or pipes attached to it.

Step 3: Remove the Faulty Solenoid Valve

Once the wires and tubing are disconnected, remove the mounting bolts or screws securing the valve in place. Gently pull out the old solenoid valve, being mindful of any debris or buildup in the system that could indicate further maintenance needs.

Step 4: Install the New Solenoid Valve

Position the new solenoid valve correctly, ensuring alignment with the existing system. Apply pipe tape or a thread sealant to prevent leaks, then secure the valve’s connections firmly without over-tightening. Confirm that the installation follows the manufacturer’s guidelines.

Step 5: Reconnect Electrical Wires and Test

Reconnect the electrical wiring, referring to the earlier picture for accuracy. Turn the power and fluid supply back on, then activate the system to test the new solenoid valve. Listen for proper operation, check for leaks, and observe whether the valve functions as expected.

Solenoid Valve Replacement FAQs

How Much Does It Cost to Replace a Solenoid Valve?

The cost of replacing a solenoid valve varies based on its type and application. Small household solenoid valves typically range between $20 and $50, while industrial solenoid valves can cost $100 to $500. In automotive applications, replacing a transmission solenoid valve can range from $150 to $400, including labor costs. If you decide to DIY and buy parts at FridayParts, you can get the best-quality solenoid valve while saving a brunch of money!

What Happens When a Solenoid Valve Goes Bad?

A failing solenoid valve can cause system-wide issues, including irregular flow, pressure drops, leaks, or complete shutdowns. In some cases, a malfunctioning valve can disrupt entire operations, leading to performance inefficiencies and potential damage to other components.

What is the Lifespan of a Solenoid Valve?

The average lifespan of a solenoid valve depends on its usage and maintenance. In general, a well-maintained solenoid valve can last anywhere from 1 to 10 years. Factors such as operating conditions, environmental exposure, and duty cycles significantly affect longevity.

How to Extend the Lifespan of a Solenoid Valve?

Extending the lifespan of a solenoid valve requires proactive maintenance and proper usage. Regular cleaning of internal components prevents dirt buildup, which can cause blockages and malfunctions. The first thing you would like to do is ensure that the valve operates within its recommended voltage range, which reduces electrical stress on the coil. Installing filters in fluid systems prevents debris from entering the valve and causing premature wear. Also, avoiding excessive use by selecting a valve rated for the correct duty cycle can significantly prolong its lifespan. Last but not least, regular inspections of connections and seals help prevent leaks and electrical shorts, reducing the likelihood of unexpected failures. I believe with proper care, your solenoid valve could definitely last longer!

Conclusion

Replacing a solenoid valve may seem technical, but following a systematic approach makes the process straightforward. Recognizing the symptoms of a failing solenoid valve early and acting promptly can prevent costly damage and system inefficiencies. By ensuring regular maintenance, choosing high-quality parts, and properly installing replacements, you can extend the lifespan of your solenoid valves and maintain optimal performance. If you need a reliable replacement solenoid valve, check out our selection of high-quality electrical parts to find the right fit for your system!