When operating your tractor, backhoe, and more, have you ever felt something strange with your steering wheel? When your machine starts to wander or the steering feels sloppy, it’s a clear sign that the idler arm or the pitman arm is wrong. You’re likely asking, what is a pitman arm, and what is an idler arm? More importantly, how do you tell which one is failing? Don’t worry, this guide will have you covered. We will break down everything you need to know about the Idler arm vs pitman arm.

What Type of Steering System Has a Pitman Arm?

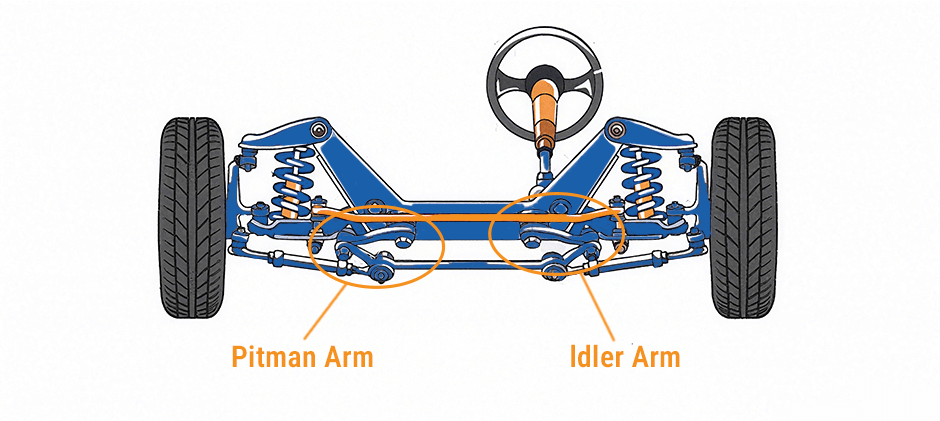

First, let’s set the scene. Both the Pitman arm and idler arm are essential players in a specific, heavy-duty setup known as a parallelogram steering system (or recirculating ball system).

You won’t find this in most modern cars. Still, it’s the go-to system for equipment that needs strength and durability, including:

- Heavy-duty and commercial trucks

- Tractors and agricultural machinery

- Backhoes and construction equipment

- Older SUVs and 4x4s

In this system, the idler arm and Pitman arm are not rivals; they are partners that must work in perfect sync to provide reliable steering.

What It Is and What It Does

To answer the question, “What is a Pitman arm?”—think of it as the muscle of your steering system. It is the active component that initiates the entire steering movement.

- It connects directly to the steering gearbox output shaft.

- When you turn the steering wheel, the gearbox translates that rotation into a powerful, sweeping arc motion in the Pitman arm.

- This swinging motion pushes or pulls the main steering rod (the center link), commanding the wheels to turn. It is the direct link between your steering input and the force that moves the wheels.

The Idler Arm

Now for its partner. What is an idler arm? It’s the stabilizer of the steering system. It doesn’t create any force; its job is purely for support and guidance.

What Does the Idler Arm Do?

- It bolts directly to the machine’s frame or chassis on the opposite side of the Pitman arm.

- Its sole purpose is to provide a solid, stable pivot point for the other end of the center link.

- It mirrors the movement of the Pitman arm, ensuring the center link stays level and moves smoothly from side to side. Without the idler arm, the linkage would flop up and down, making precise steering impossible.

Idler Arm vs. Pitman Arm: 4 Key Differences

While they work together, their individual jobs and failure points are very different. Here’s a more detailed look at the idler arm vs. pitman arm comparison.

1. Function: Active Power vs. Passive Support

The clearest difference is their function. The Pitman Arm is an active component that transmits power from the steering gearbox. It does the work. The Idler Arm is a passive component that simply provides a pivot point. It supports the work.

2. Location: Driver’s Side vs. Passenger’s Side

Their locations are a mirror image of each other.

- The Pitman Arm is almost always on the driver’s side, connected to the steering gearbox.

- The Idler Arm is on the passenger’s side, bolted securely to the machine’s frame.

3. Movement Under Load: The Telltale Diagnostic Difference

This is the most important difference when you’re trying to find a problem.

- A worn Pitman Arm typically shows play at its joints. You’ll see looseness where it connects to the gearbox or where its ball joint connects to the center link. The movement is a sloppy version of its intended arc.

- A worn Idler Arm fails at its pivot. The most common sign is vertical movement. When you test it, you will see the entire arm assembly moving up and down, which it should never do.

4. Force Dynamics: Giving vs. Receiving

The Pitman arm gives the force. It’s built to handle the immense torque from the gearbox. The idler arm receives the force. It’s designed to withstand the lateral push and pull from the center link and keep it stable.

When the Idler Arm vs. Pitman Arm Fails

Because they are part of the same team, a problem with either one can cause very similar symptoms for the operator.

- Steering Wheel “Slop”: A “dead zone” where turning the wheel does nothing.

- Steering Wander: The machine drifts left or right, requiring constant correction.

- Popping or Clunking Noises: Loud pops or clunks when turning at low speeds.

- Uneven Tire Wear: The front tires wear out quickly on the edges.

How to Test Idler Arm vs. Pitman Arm Wear

This simple test will help you identify exactly where the problem is.

1: Safety First

- Park on a solid, level surface.

- Engage the parking brake and chock the rear wheels.

- Turn the engine OFF, but leave the key in the “on” position to unlock the steering wheel.

2: The Test

- Have a helper sit in the cab and rock the steering wheel back and forth, just enough to take up the slack.

- With a flashlight, get a clear and safe view of the steering linkage underneath the machine.

3: What to Look For

- To Check the Idler Arm: Watch the idler arm where it mounts to the frame. If you see it moving up and down by more than 1/4 inch (6-7mm), it is worn out and must be replaced.

- To Check the Pitman Arm: Watch the Pitman arm’s connection points. If you see play at the steering box or at the ball joint before the center link moves, the Pitman arm or its joint is worn.

Ensure Your Safety with FridayParts

Ignoring a worn idler arm or Pitman arm is a serious risk, which will cause operator fatigue, tire wear, and even the possibility of losing steering control. So proactive inspection and maintenance are essential; don’t wait for a failure to happen.

If your inspection reveals a worn-out component, FridayParts has the solution. We offer high-quality, durable Pitman arms and idler arms specifically designed for the demanding applications of your off-road equipment, as well as other idler components. Shop our full catalog today!