When your heavy equipment key won’t turn, gets stuck, or the engine refuses to start, the issue is often a faulty ignition lock cylinder. On a job site, that means downtime and lost productivity.

This guide walks you through what the lock cylinder does, the signs it’s failing, and simple steps to safely remove and replace it so your machine can get back to work.

What Is an Ignition Lock Cylinder?

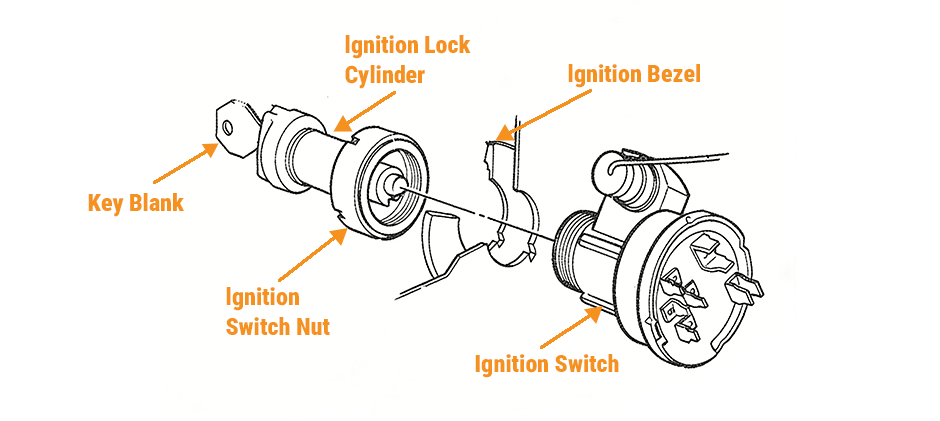

The ignition lock cylinder is the mechanical part where you insert the key. When you turn the correct key, the internal pins align, allowing the cylinder to rotate. That rotation triggers the electrical ignition switch, sending power to the starter and engine systems.

Because construction and farm machines work in dusty, high‑vibration environments, lock cylinders gradually wear out, jam, or lose electrical contact.

Common Symptoms of a Failing Lock Cylinder

Before replacing anything, confirm that the problem isn’t a weak battery or a bad starter.

| Symptom | Possible Cause |

|---|---|

| The key is hard to insert or turn | Worn pins or contaminants inside the lock |

| Key stuck or won’t come out | Internal spring or pin failure |

| Dash lights won’t turn on (battery good) | The cylinder is not triggering the ignition switch |

| The key turns, but the engine won’t crank | Broken internal connection to the starter circuit |

If several of these signs appear together, your ignition lock cylinder likely needs replacement.

Tools & Safety Preparation

Required Tools

- Service manual for your specific machine

- Safety glasses

- Screwdrivers (Phillips & flathead)

- Pick, awl, or stiff paperclip

- Socket or wrench set

Safety Steps

- Park on level ground and lower all attachments.

- Disconnect the negative battery terminal first. Heavy‑equipment batteries store high current — skipping this can cause serious electrical shock or fire.

- If your cab has airbags (SRS), disable the system per your service manual before working near the steering column.

Step‑by‑Step Replacement Diagram

Step 1: Access the Cylinder

Remove dashboard or steering column covers by undoing screws or clips. Keep hardware organized.

Step 2: Position the Key (CRITICAL FIRST STEP)

Insert the key and turn it to the specified ON or ACC position (refer to your manual). This must be done BEFORE disconnecting the battery. This step aligns the internal retaining tab with the release hole.

Step 3: Disconnect Power for Safety

Now that the key is in position, go to the battery and disconnect the negative battery terminal. This ensures all subsequent steps are electrically safe.

Step 4: Release and Remove the Cylinder

Locate the small release hole on the cylinder housing. Insert your pick, awl, or paperclip to firmly press the retaining tab inside.

While holding the tab down, grip the key and pull the entire cylinder assembly straight out of the housing.

Step 5: Install the New Cylinder

- Insert the new key into the new cylinder.

- Turn the key to the same ACC/ON position used for removal.

- Align and push the cylinder into the housing until it clicks in place.

- Tug lightly on the key to confirm it’s locked.

Step 6: Test Operation

Re‑connect the battery and check these:

- Key turns smoothly through OFF → ACC → ON → START.

- Dashboard lights activate at ON.

- The engine starts in START and shuts off normally.

If all works correctly, reinstall the column or dash covers.

Special Note: Chipped Keys & Immobilizers

Some newer or high‑value machines use anti‑theft keys with transponder chips. Replacing only the mechanical lock cylinder isn’t enough — the new key must be programmed to the Engine Control Module (ECM).

If not, the engine may crank but won’t start. Programming usually requires a dealer’s diagnostic tool or key programmer.

Final Checklist

- The new cylinder matches OEM specs

- All positions (OFF/ACC/ON/START) function correctly

- Battery connections re‑secured and protected

- Keys turn easily, and no panels are loose

Final Takeaway

Replacing a faulty ignition lock cylinder is a manageable task for any hands‑on owner or technician. With proper safety steps and a correct part match, you’ll quickly restore reliable starts, protect your machine from theft, and reduce downtime on site.

For high‑durability replacements built for off‑road conditions, check FridayParts ignition lock cylinders designed for loaders, excavators, tractors, and other heavy‑duty machinery.