If you look under the hood or behind the grille of a high-performance vehicle or heavy machinery, you might see two similar-looking components. Both are heat exchangers with fins and tubes and are crucial for engine health. Although a radiator and an intercooler look alike, they serve different functions. This guide will explain what an intercooler and radiator do, how they work, and highlight the key differences between them.

What Is an Intercooler?

An intercooler is a heat exchanger designed for turbocharged or supercharged engines. It cools down the hot, compressed air from the turbo before it enters the engine. If you want to know more about the intercooler, you can read: What Is an Intercooler?

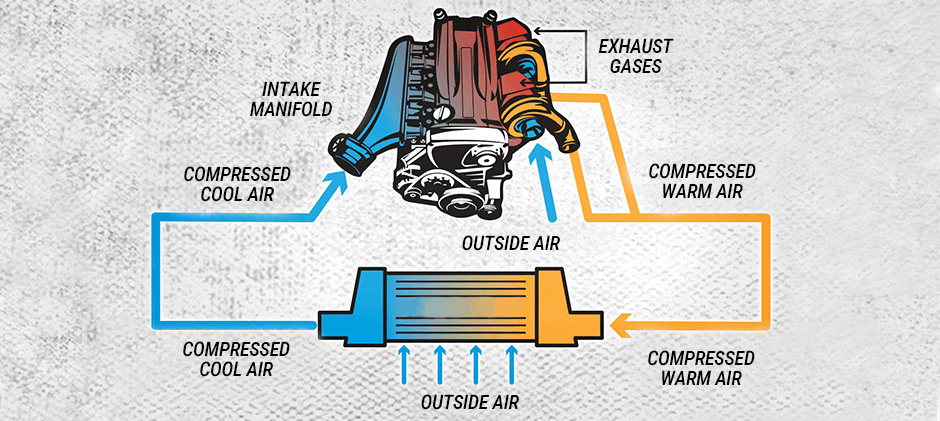

As a turbocharger compresses air, the air heats up significantly. The intercooler reduces the temperature of this “charge air.” There are two main types:

- Air-to-Air Intercoolers: The most common type, which uses the cool, ambient air flowing over the vehicle to cool the charge air inside.

- Air-to-Water Intercoolers: These use a separate circuit of liquid coolant to cool the charged air, making them more compact but also more complex.

By cooling the air, the intercooler increases its density, packing more oxygen molecules into the same volume of air. This leads to more efficient and powerful combustion.

Placement

The intercooler is usually positioned near the front of the equipment, often behind the bumper or grille, to maximize airflow. Some equipment may also have a top-mounted intercooler, typically situated on the engine or near the intake manifold. Air-to-water intercoolers offer more flexible placement options and can be located anywhere within the engine bay, depending on the setup.

Advantages

- Directly Increases Horsepower: Cooler, denser air enables the engine to burn more fuel, resulting in more powerful combustion and an outstanding increase in horsepower and torque.

- Improves Engine Safety: It helps prevent a dangerous condition called “engine knock” or detonation, which can occur when intake air becomes too hot.

- Boosts Efficiency: A more complete combustion of the air-fuel mixture makes for better fuel economy under certain conditions.

Disadvantages

- Only for Forced Induction: An intercooler is ineffective on a naturally aspirated engine.

- Adds Complexity: It requires additional piping and can increase the equipment’s weight.

- Cause Pressure Drop: A poorly designed intercooler can restrict airflow, leading to a loss of boost pressure before the air reaches the engine.

What Is a Radiator?

A radiator is the heart of your engine’s cooling system. It’s mainly used to dissipate the intense heat generated by the engine block during operation to prevent it from overheating.

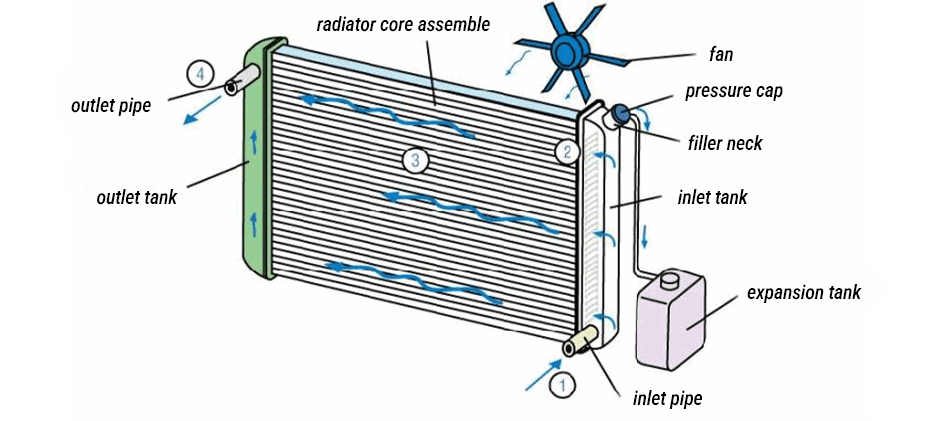

The radiator is part of a closed loop. A liquid called coolant circulates through engine passages, absorbing heat. This hot liquid then flows to the radiator, but only when the engine is hot enough to open a valve called the thermostat. Airflow across the radiator’s fins cools the liquid down before it is pumped back into the engine to absorb more heat.

Radiators can be categorized in two main ways: by the direction the coolant flows through them, and by the number of cooling tubes they contain.

1. Downflow vs. Crossflow

This describes the path the coolant takes to get from the inlet to the outlet.

Downflow Radiator

A downflow radiator can be identified by its vertical fins. In this design, coolant enters a tank at the top, flows down through the core, and then exits from a tank at the bottom. This taller, narrower style had engine bays that could accommodate its vertical shape.

Crossflow Radiator

A crossflow radiator features horizontal fins. Here, coolant enters a tank on one side of the radiator and flows across the core to an exit tank on the opposite side. This short, wide design is the standard for virtually all modern equipment because it fits better in contemporary engine bays and is generally more efficient at cooling.

2. Two-Row vs. Three-and-More Row

This refers to how many rows of tubes the radiator has to carry the coolant. The “rows” are the lines of tubes that carry coolant through the radiator core. As a general rule, adding more rows increases the surface area for heat to escape, so a 3-row radiator typically has more cooling capacity than a 2-row radiator.

But the number of rows doesn’t mean everything. A well-designed 2-row radiator with wide tubes can easily outperform a cheap 3-row radiator with very narrow tubes, as larger tubes allow for better coolant flow. Furthermore, a radiator with too many rows can become so thick that it restricts airflow, which hurts its cooling ability.

Placement

An equipment’s radiator is almost always placed at the front, directly behind the grille, ensuring it receives a steady flow of fresh air when the equipment is in motion.

Advantages

- Essential for Survival: It is necessary for preventing engine overheating and ensuring long-term reliability.

- Protects the Entire Engine: It keeps critical components like pistons, cylinders, and head gaskets at their safe operating temperatures.

- Proven Technology: It’s a simple, effective, and reliable system.

Disadvantages

- Not a Performance-Adder: A radiator doesn’t add horsepower; it simply allows the engine to run properly.

- Potential Point of Failure: Leaks, clogs from sediment, or fan failures can lead to overheating.

4 Key Differences Between a Radiator and an Intercooler

1. Function

- Intercooler: It boosts engine performance by transferring cool, dense air, increasing horsepower and torque, much like drinking a cold sports drink during exercise refreshes you and boosts energy. This allows for more complete combustion, resulting in higher output and efficiency, particularly in turbocharged or supercharged engines. Cooler air also reduces pre-ignition or knocking, enabling more aggressive timing and further power gains.

- Radiator: A radiator is mainly used to maintain engine operation and longevity by preventing overheating, acting like the skin and sweat, which regulate body temperature. It doesn’t increase power directly but dissipates heat from combustion, ensuring components stay at safe temperatures, preventing reduced efficiency, damage, or failure. When you overheat, sweating cools you down through evaporation.

While both are cooling system parts, they share different functions. The radiator mainly ensures the engine stays within safe temperature limits to prevent failure. The intercooler, on the other hand, specifically boosts performance by delivering cooler, denser air for more power and better fuel economy.

2. Working Process

Here’s a step-by-step process for them.

Intercooler

- Compressing Air: A turbocharger uses exhaust gases to spin a turbine, which compresses incoming air. This compression pushes air molecules closer together but also heats the air significantly.

- Hot Air Enters the Intercooler: The hot, compressed air, known as “charge air,” flows from the turbo to the intercooler through an inlet pipe.

- Heat Exchange Occurs: The intercooler acts like a radiator for air, with charge air passing through small tubes and passages, covered externally by thin metal fins.

- Cooling with Outside Air: As your vehicle moves, cooler external air flows over these fins from the grille, absorbing heat from the tubes and carrying it away.

- Cooler, Denser Air Exits: The cooled charge air is now denser, containing more oxygen in the same space, and flows into the engine’s intake.

- More Power is Created: Cooler, oxygen-rich air enables the engine to burn fuel more efficiently and powerfully, boosting horsepower and torque.

Radiator

- Engine Creates Heat: Combustion generates high heat, which is managed by circulating a coolant mixture of antifreeze and water through passages in the engine block using a water pump.

- Coolant Absorbs Heat: As the coolant moves through the hot engine, it takes up excess heat and becomes very hot.

- Thermostat Opens: The thermostat acts as a gate. When the engine is cold, it remains closed to help the engine warm up quickly. Once the coolant reaches about 195-220°F (90-104°C), it opens.

- Hot Coolant Enters the Radiator: The hot coolant flows into the radiator’s inlet tank and then through a network of thin tubes in the core.

- Heat Exchange Occurs: These tubes, covered with fins like the intercooler, transfer heat to the outside air as it flows past, whether from movement or a fan.

- Cooled Coolant Returns to the Engine: After releasing heat in the radiator, the cooled coolant collects in an outlet tank and is pumped back into the engine. This cycle repeats to prevent overheating.

3. Application

- Radiator: Every water-cooled engine needs a radiator to manage the heat generated during operation, maintaining its optimal core temperature. This is a fundamental component of any liquid-cooled engine.

- Intercooler: While an intercooler is more specialized, it is only necessary in engines with forced induction systems like turbochargers or superchargers, which compress intake air and raise its temperature.

An excavator can operate efficiently with only a radiator to meet its cooling needs. However, an engine with an intercooler can’t lack a radiator, since the intercooler’s function complements the engine’s core cooling system, which always relies on the radiator.

4. Radiator vs. Intercooler Cost in Off-Road Machinery

When budgeting for the replacement of cooling components in off-road machinery, the costs can fluctuate based on the equipment’s make, model, and size. While it is impossible to give the exact pricing, we can share price ranges for both radiators and intercoolers for consideration.

- Radiator: For many standard pieces of heavy equipment, such as excavators or loaders, the replacement cost for a radiator can range from around $700 to over $1,700 for the part alone. Aftermarket parts for common models like a Case backhoe or Caterpillar excavator might fall between $500 and $900. Labor costs to install the radiator can add several hundred dollars, depending on the complexity of the job.

- Intercooler: The cost of an intercooler for similar machinery often starts in a comparable range, but can escalate quickly. For example, a replacement intercooler for a John Deere compact tractor might be around $600, while a more robust unit for a large John Deere 8000 series tractor or sprayer can cost over $2,300. For high-performance or specialized heavy machinery, a complex air-to-water intercooler can be more expensive to replace than a standard radiator. In some cases, the total replacement cost for an intercooler, including labor, can reach between $1,100 and $1,500 or more.

In summary, while the parts cost for a standard radiator and intercooler can be comparable, the price for specialized or high-performance intercoolers often exceeds that of radiators. Due to this wide variability, it is always best practice to get a quote specific to your machine to ensure an accurate budget for repairs.

Which One Do You Need?

The answer is determined entirely by the engine’s design.

- If your machine has an older, naturally aspirated engine, you only need a radiator to manage engine heat.

- If your machine has a turbocharged diesel engine, you need both: a radiator to cool the engine itself, and an intercooler to cool the compressed charge air.

They work in parallel to manage two different sources of heat. You cannot replace one with the other, and removing either from a system that requires it would lead to immediate power loss and eventual catastrophic engine failure.

How to Make the Right Choice?

The real choice isn’t between a radiator and an intercooler, but in selecting the right type, size, and durability level for your specific machinery and its working environment. The cooling demands in the off-road world are far more intense than on the highway.

A compact utility tractor used for intermittent light tasks has very different cooling demands compared to a large excavator or mining haul truck working continuously under heavy load in high ambient temperatures. These heavy-duty applications require oversized, highly durable radiators and robust intercoolers to resist constant vibration and clogging from dust and debris.

In any case, when replacing a cooling component, don’t be afraid to speak with a parts expert. They can ensure you get a part that meets or exceeds OEM specifications for your needs and budget. Reliable suppliers like FridayParts offer such services. Feel free to contact us if you have any questions.

By understanding their distinct roles, you can better maintain, upgrade, and appreciate the brilliant engineering that keeps your heavy machinery running cool, strong, and reliably on the job site.

Conclusion

Both the radiator and the intercooler are essential cooling components, but they serve unique and separate functions. The radiator protects the engine from its heat, while the intercooler unlocks the full potential of a turbocharged system. To keep your engine running at its best, both systems must be in perfect working order.

Over time, the components connecting these systems—especially the intercooler hoses and radiator hoses—can crack, leak, or fail, leading to power loss or dangerous overheating. When it’s time for a replacement, choosing a durable, high-quality part is essential. It’s wise to choose reliable suppliers like FridayParts. Visit FridayParts.com and explore our large stock of high-quality radiators and intercoolers!