Welcome back to the FridayParts video channel. FridayParts is your go-to source for expert insights on heavy machinery. Our host from a recent video highlighted a critical component that often dictates the smooth operation of your aerial lift: the lift control box. As pointed out, a staggering “nearly 30% of lift failures start with this” very part. If you’ve ever felt that uneasy wobble high up, wondering about your lift’s reliability, understanding the lift control box might be the key.

Today, we’re diving deep into what makes this component tick, how to choose the right AWP replacement, especially if you’re running equipment like a Skyjack SJ 3219, and how to maintain it for safety and longevity.

What is a Lift Control Box?

The lift control box is essentially the command center of your aerial lift. It’s not just a box with buttons; it’s a sophisticated piece of engineering. A key feature often found in these units is proportional control.

“Think of it like a gas pedal for hydraulics,” our expert explains. “The harder you push or the more input you give, the smoother it adjusts the oil flow to eliminate jerks and keep your lift steady.”

This proportional control is vital. It translates your joystick movements or button presses into precise hydraulic actions, allowing for smooth ascents, descents, and positioning. Without a properly functioning lift control box, you could experience jerky movements, sudden stops, or a complete lack of response – all dangerous scenarios when working at height.

4 Essential Checks for Buying the Right Lift Control Box

Choosing a replacement lift control box isn’t just about finding something that looks similar. Precision is key. Let’s use the Skyjack SJ 3219 as an example to illustrate the critical checks you need to make:

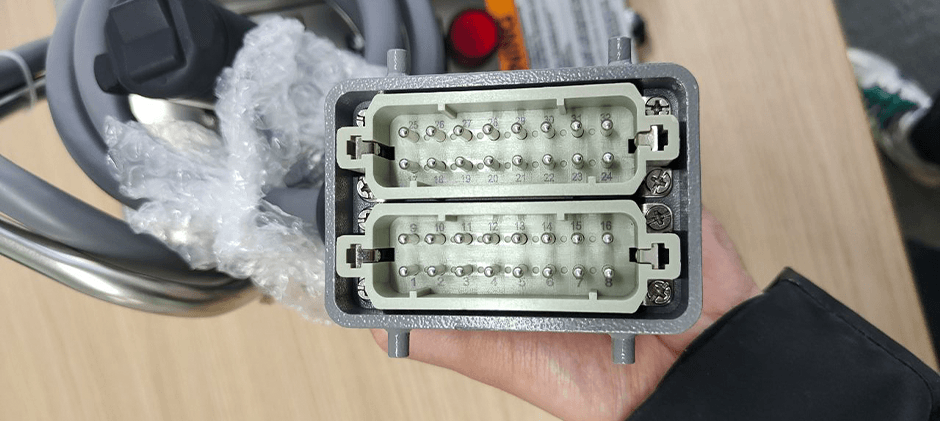

1. Pin Configuration on the Connector

The electrical connector on the lift control box has a specific number and arrangement of pins that plug into your lift’s wiring harness. These pins transmit power and signals. For the Skyjack SJ 3219, it “uses an 8-pin male plug.” If your replacement has a different pin count or configuration, it simply won’t connect correctly, or worse, could cause electrical issues.

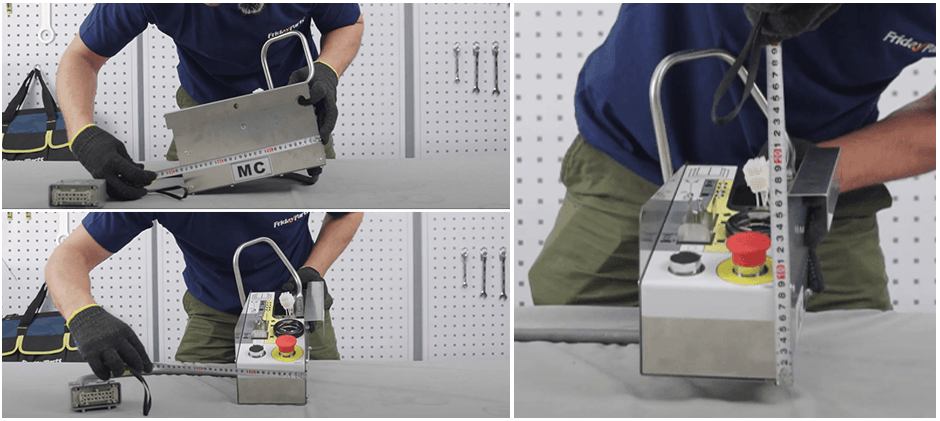

2. Confirm Dimensions

The control box you buy needs to fit correctly into its designated mounting spot on the lift. An ill-fitting box can be difficult to install, may not be secure, or could interfere with other components.

3. Part Number Compatibility

The part number is like the ID card of every part. This is often “the safest way to make sure it fits.” The part number ensures that the internal electronics, software (if applicable), and physical design are an exact match for your lift model’s requirements.

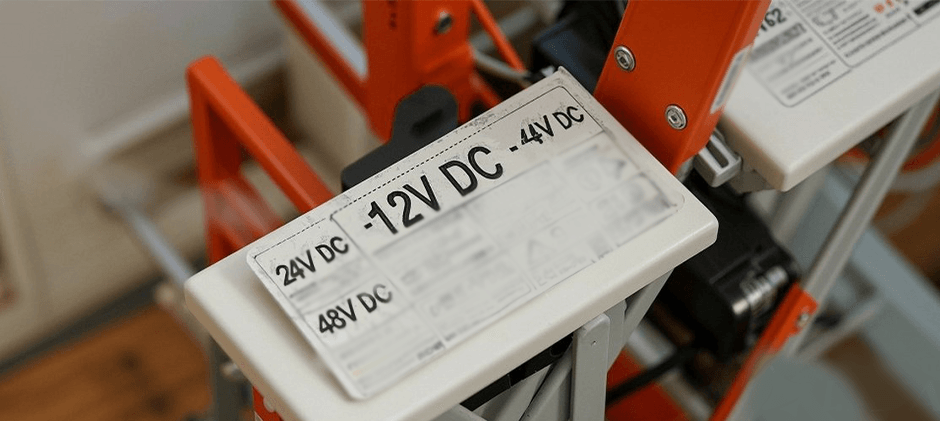

4. Voltage Matching:

The operating voltage of the lift control box must match your lift’s electrical system power supply. “Common options are 12volt DC, 24volt DC, and 48volt DC, and they are not interchangeable. Make sure you choose the one that matches your machine’s voltage.”

How to Maintain Your Lift Control Box?

Once you have the right lift control box installed, proper maintenance is crucial to keep it and your lift running safely and efficiently for longer.

Regular Visual Checks (Monthly Recommended):

- Inspect connections: Ensure all plugs are securely seated.

- Examine wiring: Look for any frayed wires, cracked insulation, or signs of pinching.

- Check for loose fittings: Ensure the box itself and any components within (if accessible) are secure.

- Look for corrosion: Especially around connectors and terminals. Clean as needed with appropriate contact cleaner.

- “Give it a quick look over every month.”

Annual Professional Inspection:

- It’s wise to “have a certified tech do a full inspection” at least once a year.

- This deeper check can identify less obvious issues.

- Technicians will also “clear out the dust, the debris, [and even] critters’ nests” that can accumulate and cause overheating or short circuits.

The Power of a Maintenance Logbook:

- This is a simple yet powerful tool. “Jot down dates, what you checked, any fixes you made.”

- Benefits: “Trust me, that paper trail will save you so many headaches down the road by spotting issues early.” A logbook helps track the component’s history, identify recurring problems, and can be invaluable for troubleshooting.

Conclusion

Your lift control box is more than just an interface; it’s a critical safety and operational component. In construction, downtime equals financial loss. Understanding how to select the correct replacement and performing regular maintenance are key to ensuring your aerial lift operates reliably and safely. If you’re searching for a dependable replacement lift control box for your Skyjack, JLG, Genie, or other aerial equipment, we at Fridayparts are here to help. Choosing FridayParts AWP spare parts and working with authorized technicians is not just a service choice, but also a business investment. By investing in FridayParts control boxes, you are not just maintaining your machine; you are preserving your equipment’s heritage of performance and dependable service for years to come!