It’s important to know the difference between a muffler vs exhaust system, and keep the engine running right. They’re connected, but each has its own job. Together, they control emissions and cut down on noise. Learn how these two work together, plus the different signs that either one is acting up. Catch problems early, and you’ll avoid power loss, bad emissions, or a really loud operator cab.

Introducing the Muffler vs. Exhaust System

A muffler is not the same as an exhaust system. The exhaust system is the whole system, but the muffler is just one component. The exhaust system is a complete set of lines and components from the engine all the way to the exhaust port. Its job is to safely remove hot, harmful exhaust gases. away from operators, while at the same time bringing emissions into line with regulatory requirements like Tier 4 Final through a post-treatment unit. Also, try not to affect the engine’s power performance. The muffler’s task is to reduce noise. It is a specialized component in the exhaust system and is usually installed near the end of the exhaust. Used to reduce the loud noise generated by diesel engines.

The Muffler and Exhaust System Function

The whole exhaust system has to strike a balance between performance, emissions control, and noise reduction. It’s got three main jobs:

- Safe gas removal: It flushes toxic gases like carbon monoxide and nitrogen oxides out of the operator’s cab and releases them safely into the air. A leak here is super dangerous.

- Sticking to emissions rules: Tough standards like Tier 4 Final and Stage V mean you can’t do without the exhaust after-treatment system (DPF, SCR). It cuts pollutants down to legal levels—saves the environment and keeps you from getting hit with fines.

- Keeping the engine running strong: A good exhaust system keeps just the right amount of backpressure. Too much, and the engine’s working overtime. Too little, and the turbo doesn’t do its job right. A solid system nails that sweet spot for maximum power and fuel efficiency.

The muffler’s main job is noise reduction, but it’s just as critical:

- Operator comfort: It cuts down cab noise big time, so operators don’t get tired easily. That means they stay focused and safe on the job.

- Job site rule compliance: Most construction sites and local governments have strict noise limits. A working muffler makes sure your machine stays within those limits—so you won’t have to shut down work halfway through.

Location of the Muffler and Exhaust System

For most equipment, like tractors, loaders, and excavators, the setup is pretty much the same every time.

The exhaust system starts right at the engine block with the exhaust manifold. The pipes usually run up or along the side of the engine to the turbocharger. Right after that, you’ll see a big, often insulated box or canister that’s the after-treatment unit with the DPF and SCR inside. Follow the pipes past that unit, and you’ll hit the muffler. It’s usually the last big part in the line before the final exhaust outlet.

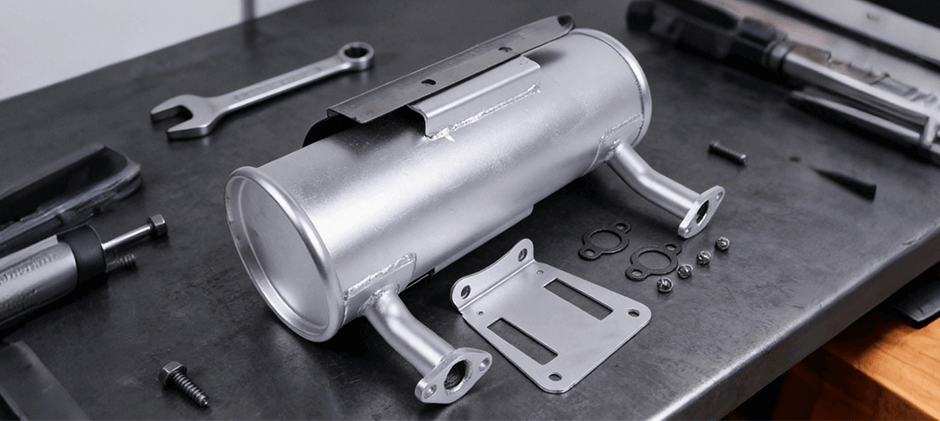

The muffler itself is typically a big, cylinder or oval-shaped canister. It’s made of thick aluminized or stainless steel to stand up to heat, vibration, and rust. You’ll find it after the emissions control gear and right before the exhaust stack—the vertical pipe that blows the gas out above the machine. Being at the end of the line lets it quiet the exhaust gases down just before they’re let out.

Muffler vs. Exhaust: Common Problem Signs

When your machine acts up, a lot of folks get confused: Is it just the muffler that’s bad, or is something else wrong with the exhaust system? Actually, you can figure out the rough cause just by watching for some obvious signs.

Common Signs of a Bad Muffler

The purpose of a muffler is to reduce noise, so once it breaks, the first thing that changes is almost always the sound.

- Exhaust gets suddenly loud: If the device sounds like “without a muffler” at once, it’s usually because the internal partition is broken or the housing has rusted through.

- Metallic rattling or clunking noises: At idle or low RPMs, there is a sound of metal knocking near the muffler, which often indicates that internal parts have become loose.

- Visible holes or heavy rust: A quick visual check will spot cracks, holes, or big rust spots on the muffler. These let exhaust fumes and noise leak out early.

Common Signs of a Broader Exhaust System Problem:

If the issue isn’t just the muffler, it’ll usually mess with the engine’s performance—even trigger warning lights on the dash.

- Dashboard warning lights come on: The check engine light, DPF light, or DEF warning light comes on, which is often related to the after-treatment system, such as a clogged DPF, an abnormal sensor, or a problem with the SCR system.

- Loss of power and higher fuel consumption: The equipment feels lost power and uses more oil than before, often due to a clogged DPF or a deformed exhaust pipe causing excessive back pressure.

- Continuous smoke: A little smoke on cold starts is normal. But if it’s belching black smoke nonstop, that’s usually a sign of poor combustion or a failing DPF. White smoke likely points to issues with the SCR system or DEF injection.

- Hissing/tapping noises plus exhaust smell: If the exhaust manifold or pipes spring a leak, you’ll usually hear a hissing or tapping sound that gets louder as the engine revs higher.

And if you smell exhaust fumes inside the cab? That’s a major safety risk—you gotta fix it right now.

Summary

Want to quiet things down, boost efficiency, or tweak exhaust sound? You gotta think about how all parts work together. If you need to replace a muffler or any other exhaust parts, FridayParts has you covered. We stock top-quality parts that fit your equipment perfectly. Head to our one-stop shop and choose what you need!