If you’ve ever explored exhaust system modifications, you may wanna ask a question: resonator vs muffler — what’s the difference?

This practical guide explains what each part does, what happens if you remove it, and how to make the right choice for your machine and your budget.

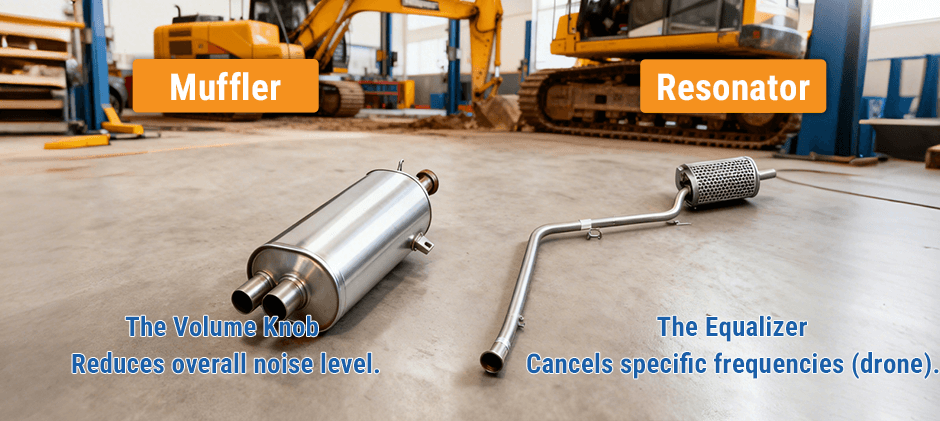

The Muffler: The Volume Knob

When comparing a resonator vs a muffler, the muffler’s job is straightforward — it keeps your heavy‑equipment engine within safe and legal noise levels. Without it, the engine’s exhaust note would be harsh, loud, and non‑compliant with most work‑site noise standards.

How It Works

The muffler contains chambers and perforated tubes that quiet sound waves using two main techniques:

- Absorption: Fiberglass or acoustic packing material absorbs sound energy and turns it into heat.

- Reflection: Internal chambers reflect and cancel sound waves, reducing their energy before they exit the tailpipe.

What Happens If You Remove It? (Muffler Delete)

Removing your equipment’s muffler — often called a muffler delete — can dramatically change its noise profile.

- Massive Volume Increase: Your excavator or skid steer will get significantly louder, often exceeding work‑site noise thresholds.

- High Drone Risk: Without sound dampening, low‑frequency droning can fatigue the operator over long shifts.

- Safety & Legal Issues: Excessive exhaust noise may violate OSHA or local compliance standards.

- Minor Weight Reduction: You might save a few kilograms, but the trade‑off in comfort and safety isn’t worth it.

In short: A muffler delete gives a louder, rawer sound — but often reduces operator comfort and site compliance.

The Resonator: The Tone & Drone Police

Next up in the resonator vs muffler sound debate is the resonator. Unlike the muffler, it doesn’t primarily lower noise levels — it fine‑tunes exhaust frequencies to reduce vibration and operator fatigue.

How It Works

A resonator acts like a tuned echo chamber that uses destructive interference to cancel specific vibration frequencies:

- Unwanted sound vibrates through the exhaust.

- The resonator reflects that vibration out of phase.

- The two sound waves meet and cancel each other, reducing particular tones or droning frequencies.

What Happens If You Remove It? (Resonator Delete)

Removing the resonator — a resonator delete — changes tone and cabin feel more than volume:

- Slight Noise Increase: The exhaust note becomes more pronounced.

- Tone Change: Deeper or raspier tone that some operators find “stronger.”

- Possible Drone: Removing the part designed to cancel the drone can introduce vibration resonance through the cab or chassis.

Operators often say: “The muffler quiets the noise — the resonator keeps the operator comfortable.”

Head‑to‑Head Comparison: Resonator vs Muffler

Here’s a clear resonator vs muffler difference summary for off‑road machinery:

| Feature | Muffler | Resonator |

|---|---|---|

| Primary Function | Reduces overall exhaust volume | Cancels specific vibration frequencies |

| Effect of Removal | Extremely loud; may breach site noise limits | Slightly louder, rougher tone; possible drone |

| Performance Impact | Mild reduction in exhaust flow; minor efficiency loss | Minimal impact on performance |

| Location | End of the exhaust system | Middle section of the exhaust routing |

| Common Mod | Muffler delete for noise testing | Resonator delete for simplifying exhaust design |

A Practical Guide: What Should YOU Do?

So, in the muffler vs resonator debate for heavy equipment, which should you modify or replace first? That depends on your maintenance goals, noise tolerance, and operational environment.

Step 1: Define Your Goal

Ask yourself:

- Are you aiming for quieter cab conditions for the operator?

- Or do you want a freer‑flowing exhaust for slightly improved engine response?

Pro Tip: Before removing either component, check your machine’s service manual or FridayParts filter and exhaust section. Manufacturers tune these systems for safety and compliance — changing one part can affect backpressure and emissions.

Option 1: The Cosmetic Mod — New Exhaust Tip

- What It Is: Replacing the worn or rusted outlet tip.

- Sound Change: None or minimal — purely visual.

- Cost: Low.

- Why Do It: Keeps your machine’s exhaust outlet clean and presentable.

Option 2: The Budget Mod — Resonator Delete

- What It Is: Replacing your resonator with a straight pipe.

- Result: Slightly deeper tone, less complex system.

- Pros: Inexpensive, easy weld‑on mod.

- Cons: Risk of drone or cab vibration.

A common approach for older equipment where resonators have corroded — but generally, FridayParts recommends keeping a tuned resonator for operator comfort.

Option 3: The Loud Mod — Muffler Delete / Straight Pipe

- What It Is: Removing the muffler and replacing it with a pipe.

- Result: Maximum exhaust noise, minimal restriction.

- Pros: A Louder sound can help field diagnosis of engine rhythm.

- Cons: Harsh volume, hearing protection required, fails most compliance tests.

In muffler delete vs resonator delete tests, removing the muffler always wins for loudness — but it’s rarely practical for daily operation.

Option 4: The Engineered Upgrade

For professional performance and noise control, FridayParts recommends a replacement exhaust system engineered for your specific model. Properly tuned aftermarket mufflers and resonators:

- Optimize flow and backpressure for diesel engines

- Reduce drone and vibration inside the cab

- Maintain regulatory noise limits

These systems often use bullet mufflers or resonated mid‑pipes designed to balance airflow restriction and noise reduction — perfect for off‑road excavation or hauling environments.

Special Case: Heavy Equipment Reality Check

In heavy‑duty diesel machinery like excavators, loaders, and bulldozers:

- Mufflers are large and robust, providing maximum sound reduction and safety. Many include spark arrestors to prevent fire hazards on job sites.

- Resonators (if present) are tuned to minimize low‑frequency vibrations that cause structure‑borne noise and operator fatigue.

In off‑road applications, function outweighs aesthetics. Mufflers and resonators serve performance, comfort, and safety — not sport sound.

Final Verdict

If you’re maintaining or upgrading your machinery’s exhaust:

- Start with a quality muffler replacement to maintain noise and safety standards.

- Remove or modify the resonator only if necessary for accessibility or part failure.

- Avoid removing both unless you’re testing flow under controlled conditions.

For most off‑road owners, investing in FridayParts OEM‑grade mufflers and resonators ensures optimal engine health, long‑term durability, and reduced operator fatigue — all at an accessible price.