Deciding whether to repair or replace an A/C evaporator is a common concern for many equipment operators. We’ve worked with numerous customers facing this exact situation. When they consult a repair shop, the technicians often recommend replacing the entire air conditioner evaporator. However, this often results in a hefty bill. So, is the technician’s judgment correct? Is there a more cost-effective way to do this? If you’re also struggling with the decision of whether to repair or replace your A/C evaporator, this article is perfect for you. It provides in-depth information about your A/C evaporator and offers you cost-effective methods for replacing your A/C evaporator, helping you make an informed and affordable decision.

Key Takeaways

- Labor Is the Real Cost: The A/C evaporator core itself is often an affordable aftermarket part. The high cost comes from the 10 to 20+ hours of labor required to tear down the entire dashboard and HVAC unit to access it.

- Bundle Related Repairs: Because of the extreme labor involved, it is highly recommended to replace other nearby components like the heater core and expansion valve at the same time to avoid paying for the same teardown twice.

- Don’t Delay Repairs: A leaking evaporator can lead to mold, discomfort, and serious damage to the A/C compressor if left unaddressed.

- Avoid Quick Fixes: Stop-leak products offer only short-term relief and may harm your entire A/C system in the long run.

- Replacement Is Worth It: For most machines, replacing the evaporator prevents bigger issues and is a smart investment in uptime and comfort.

What Is an A/C Evaporator and What Does It Do?

The A/C evaporator is a radiator-like component located inside your machine’s HVAC system, usually behind the dashboard. It plays a key role in the cooling loop of your air conditioning system.

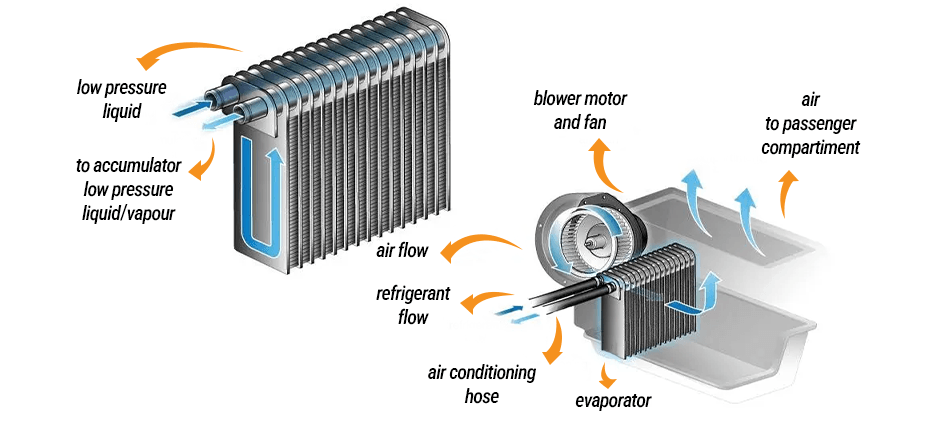

Here’s how it works:

- Cooled, high-pressure liquid refrigerant flows from the condenser into a device called an expansion valve (or orifice tube), which turns it into a very cold, low-pressure mist.

- This cold mist is sprayed into the A/C evaporator.

- The blower motor in your cab forces warm cabin air across the evaporator’s cold fins.

- The evaporator absorbs the heat from the air, instantly chilling it. This newly chilled air is what you feel coming out of your vents.

Its location is the entire reason this repair is so challenging. It is arguably the most inaccessible component of the entire A/C system, buried under a sea of wires, ducts, brackets, and the entire dashboard assembly.

What Causes an A/C Evaporator to Fail?

Off-road environments are the ultimate stress test for any mechanical component. The constant vibration, dust, and moisture create a perfect storm for A/C evaporator failure.

- Internal Corrosion: Over time, moisture can find its way into the A/C system. When this moisture mixes with refrigerant, it can form corrosive acids that eat away at the thin aluminum walls of the evaporator from the inside out, causing tiny, hard-to-find pinhole leaks.

- External Corrosion: Dirt, dust, leaves, and other debris get sucked into the HVAC system and can clog the evaporator’s fins. This trapped debris holds moisture against the metal, leading to external corrosion and eventual leaks. This is especially common in agricultural and construction equipment.

- Punctures and Cracks: The constant, jarring vibrations of heavy machinery can stress the welds and joints of the evaporator, leading to cracks and leaks over time.

In the world of heavy machinery, downtime is the real enemy. A temporary fix on a buried component like an A/C evaporator may lead to a second, more costly breakdown. If downtime is your primary concern, replacing it correctly the first time is an investment in uptime.

The Core Question: Repair or Replace?

When your A/C system fails, the big question is often: repair or replace the evaporator? While they may sound similar, the reality is very different. The evaporator core is built from delicate aluminum with narrow, complex passages. Once it leaks—usually from corrosion or cracks—there’s no reliable way to fix it. And since accessing it requires removing the dashboard, a temporary repair can lead to costly repeat labor.

In most cases, what’s called a “repair” actually refers to external issues, like replacing a leaking O-ring where the refrigerant lines connect. If a dye test confirms it’s just a fitting, that’s a quick and affordable fix. But if the leak is inside the core—and it often is—full A/C evaporator replacement is the only long-term solution. At that point, the real decision becomes whether the replacement cost is justified by your machine’s age, usage, and value.

To answer this, you must weigh the upfront cost against several critical business factors:

- The Cost of Downtime: This is the most important calculation for any commercial operation. How much revenue does this machine generate per day? A repair bill of $1,500 might seem high, but if the machine is down for a week in peak season, you could lose far more in lost contracts and productivity. In this context, the replacement isn’t a cost; it’s an investment in operational continuity.

- Operator Safety and Productivity: An operator working in a sweltering, 100°+ (38°+ C) cab is not just uncomfortable; they are a safety risk. Heat exhaustion reduces focus, slows reaction times, and dramatically increases the chance of a serious accident. A functional A/C system is a core component of a safe and productive work environment.

- The Risk of Catastrophic Failure: A leaking A/C evaporator doesn’t exist in a vacuum. As refrigerant leaks out, the A/C compressor loses the oil that normally circulates with it. This will inevitably lead to the destruction of the compressor, a far more expensive component. Ignoring the evaporator leak is effectively guarantees a much larger repair bill shortly.

For essential equipment, A/C evaporator replacement is often the only smart choice despite high labor costs. To reduce the financial burden, it’s wise to avoid dealer markups by sourcing aftermarket evaporator cores and related parts like the heater core and expansion valve. By choosing a trusted aftermarket supplier like FridayParts, you can acquire high-quality, OEM-equivalent components at a fraction of the cost, making the overall investment in the repair significantly more manageable.

The DIY vs. Professional Service

Once you’ve decided to replace the unit, the next big decision is whether to go DIY or hire a pro. With labor making up 70–80% of the total cost, DIY A/C evaporator replacement can slash your bill from $2,000 to under $500. This is often also the most effective way to save money.

The Reality of a DIY Evaporator Replacement:

Before you start unbolting panels, you must honestly assess if you are equipped for the job. You will need:

- Specialized A/C Tools: This is non-negotiable. You need a refrigerant recovery machine (it is illegal to vent refrigerant into the atmosphere), a vacuum pump to remove moisture from the system, and a set of manifold gauges to recharge it correctly.

- Extensive Mechanical Skill: This goes far beyond a simple oil change. You will be dismantling the entire operator’s station—seats, steering column, electronic modules, and the full dashboard assembly. You must be able to keep track of hundreds of bolts, clips, and electrical connectors.

- A Service Manual: You cannot do this job without a detailed, model-specific service manual to guide you through the disassembly and reassembly sequence.

- Patience and Time: This is not a one-day job. For a first-timer, plan for a full weekend or even several evenings. Rushing will lead to broken plastic tabs, stripped bolts, and forgotten connections.

For the confident DIYer, taking on an A/C evaporator replacement can lead to major savings—your time becomes the biggest investment. A cheap component failure means redoing hours of labor. That’s why at FridayParts, we offer trusted, high-quality aftermarket A/C evaporators, heater cores, and expansion valves that meet or exceed OEM standards, helping you save money without compromising on reliability.

Conclusion

Deciding whether to replace a faulty A/C evaporator is a significant financial calculation. While the upfront cost is high, a sound and effective maintenance approach can save you money on repairs, making it a necessary and worthwhile investment for any commercial off-highway machine. The risks of ignoring the problem, from operator discomfort and lost productivity to catastrophic failure of the entire A/C system, are simply too great.

When you do decide to move forward, ensure you are using high-quality parts that will last. FridayParts offers a vast inventory of affordable, durable aftermarket A/C evaporators and system components for a wide range of heavy equipment brands, helping you get this critical repair done right without breaking the bank.