Keeping your off-road machinery in top condition means you need to understand those small parts which are preventing expensive downtime, and one of these small but very important parts is the radiator hose. When this hose is having failure, your engine cooling system will lose the ability to control the temperature properly, causing overheating, poor performance, or even catastrophic engine damage. In this guide, we will help you to recognize the top 8 signs showing a radiator hose is going bad, and also explain how long these hoses can last, discuss what kinds of factors are influencing them, and show you when it is the correct time to replace them with reliable aftermarket parts

How to Tell If Your Radiator Hose Is Bad?

Every heavy machine’s cooling system has two primary hoses — an upper radiator hose that carries hot coolant from the engine to the radiator, and a lower hose that returns cooled fluid to the system.

When these hoses harden, swell, or collapse, coolant flow becomes restricted, and the engine overheats.

Here’s how operators can spot trouble early:

- Inspect visually under good lighting for cracks or melted areas.

- Check flexibility — after the engine cools, squeeze the hose. It should feel firm yet flexible.

- Look for residue — stains or dried coolant near connections usually indicate leaks.

A simple inspection routine during each service interval can make the difference between a planned part change and a full-blown engine rebuild.

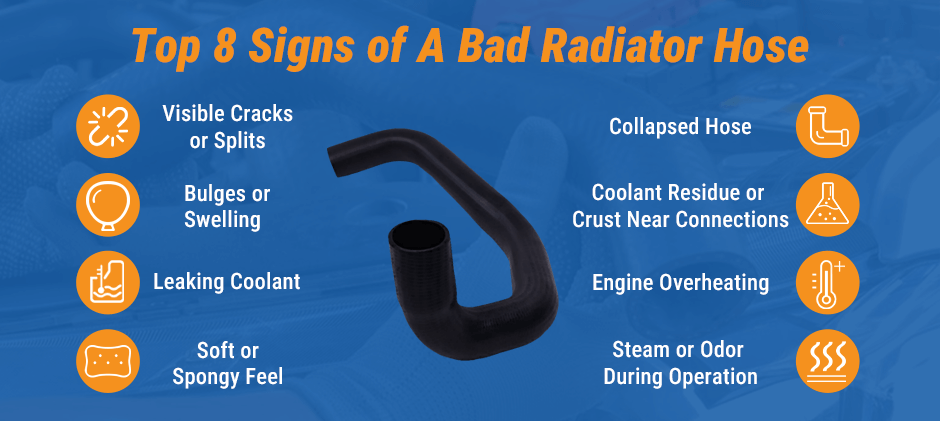

8 Signs Your Radiator Hose Is Failing

Below are eight clear indicators that your machine’s radiator hose needs attention or replacement.

1. Visible Cracks or Surface Splits

Constant temperature swings in off-road conditions—especially for construction or agricultural machines—cause rubber hoses to harden and develop hairline cracks. Once cracks appear, pressure within the cooling system can force coolant out, leading to a rapid loss of fluid and rising engine temperatures.

2. Bulging or Ballooned Sections

If parts of the hose are swollen or misshapen, internal layers have separated from heat, oil exposure, or excess pressure. A bulging hose could burst suddenly during operation, releasing coolant under pressure and halting work immediately.

Tip: Never ignore even a small bulge near a clamp or bend. It means the internal reinforcement mesh has already failed.

3. Coolant Leaks or Puddles Under the Machine

Spotting coolant stains beneath your track loader or grader is one of the most direct warning signs. Coolant can appear green, orange, or yellow depending on the blend. Low coolant levels cause overheating fast, and a leaking hose is often the culprit — either from a hole, a loose clamp, or a failed joint.

4. Spongy or Soft Texture

Squeeze the hose when cold. If it feels spongy, soft, or crunchy, the internal fabric structure is breaking down. This deterioration occurs naturally over years of exposure to heat and vibration. In high‑hour machines, spongy hoses can collapse under suction and block coolant flow.

5. Collapsed or Flattened Hose

A collapsed radiator hose restricts circulation, starving the engine of cooling capability. This can happen when the hose’s internal reinforcement wire corrodes or after a vacuum surge when starting the engine cold. A collapsed hose explains many “mystery” overheating issues in aging excavators.

6. Coolant Residue or Crust Near Connections

White or colored crust around the hose ends means a slow leak has been evaporating over time.

That residue is dried antifreeze — an early clue often missed during visual checks. It’s a good idea to remove the clamp, clean the connection, and replace the hose before the leak worsens.

7. Engine Overheating or Fluctuating Gauge Readings

When your excavator or dozer starts overheating even after cleaning the radiator or replacing coolant, a weak hose might be restricting flow. If steam appears near the radiator cap or the temperature gauge fluctuates erratically, inspect the entire hose path carefully.

8. Steam, Odor, or Visible Drips During Operation

Operators often smell the problem before they see it. A sweet coolant odor or faint steam plume points to a leak under pressure. Shut down safely and inspect before continuing work—opening the radiator while hot is extremely dangerous.

Table: Radiator Hose Warning Signs and Causes

| Sign | Probable Cause | Recommended Action |

|---|---|---|

| Cracks or splits | Aged rubber or heat stress | Replace the hose immediately |

| Bulges | Oil contamination or internal rupture | Replace, flush cooling system |

| Coolant puddles | Clamp failure or pinhole leak | Tighten or replace the clamp and hose |

| Soft hose | Fiber reinforcement decay | Replace the hose set |

| Hose collapse | Vacuum overload | Check the water pump and hose condition |

| Coolant crust | Slow evaporation leakage | Replace the hose and gasket |

| Overheating | Blocked coolant flow | Inspect both upper and lower hoses |

| Steam or odor | Active pressure leak | Turn off engine—replace after cooling |

How Long Do Radiator Hoses Last?

In off-road machinery, radiator hoses generally last 4 to 6 years, but life expectancy depends on workload and maintenance habits. Machines working in extreme environments—quarries, forests, or farms—face more dust and vibration, accelerating hose wear.

Routine inspection during fluid changes or seasonal maintenance prevents surprise failures. Replace hoses preemptively when they show surface aging, stiffness, or internal residue build-up.

Factors Affecting Radiator Hose Lifespan

Several elements influence how long hoses stay reliable in heavy-duty conditions:

- Operating Temperature: High ambient heat or prolonged idling accelerates aging.

- Pressure Spikes: Rapid engine load changes strain connectors and clamps.

- Contamination: Oil mist and hydraulic leaks degrade rubber compounds.

- Coolant Chemistry: Using an incompatible coolant mix leads to internal corrosion or swelling.

- Storage Conditions: Long idle periods or UV exposure cause cracks before operation even begins.

- Maintenance Practices: Regular coolant flushing and proper clamp torque preserve hose integrity.

Remember: heavy-duty cooling systems experience more thermal cycles than road vehicles. Proactive replacement minimizes downtime.

Maintenance and Replacement Guidance

Every operator or maintenance technician should include a hose check in their scheduled inspection. While checking, ensure that hoses are not rubbing against metal edges or moving parts. Constant vibration from large diesel engines can wear through a hose wall surprisingly fast.

When it’s time to replace, choose reinforced aftermarket radiator hoses built for the demanding conditions of off-road machinery. At FridayParts radiator hoses, you’ll find OEM-quality replacements compatible with major equipment brands — from Komatsu and Kubota to John Deere and CASE. These hoses are designed for high pressure, high heat, and long-term durability at affordable pricing.

Frequently Asked Questions

Q1: How do I safely check a radiator hose?

Wait until the engine cools, then press gently. Never check when hot, as coolant pressure can cause burns.

Q2: Can a small leak be sealed temporarily?

Only briefly. A temporary patch may fail under pressure. Always schedule a full replacement soon after.

Q3: Should I replace both hoses at the same time?

Yes. Upper and lower hoses age at similar rates. Replacing both ensures balanced performance and prevents sequential failures.

Summary

An unplanned shutdown on the working site is making the loss much bigger than the cost of any parts replacement. Doing the regular checking and changing of the radiator hose can make sure your off-road machinery keeps running in low temperatures, with safety and high efficiency. No matter you are maintaining only one excavator or a whole fleet, FridayParts can also provide you the reliable and price-reasonable radiator hoses. We are giving the heavy-duty equipment users fast shipping OEM-level aftermarket parts, which are designed specially for facing the very harsh off-road working conditions. Keeping the cooling system in the best condition means your projects can continue according to schedule — and this thing is the real priceless.