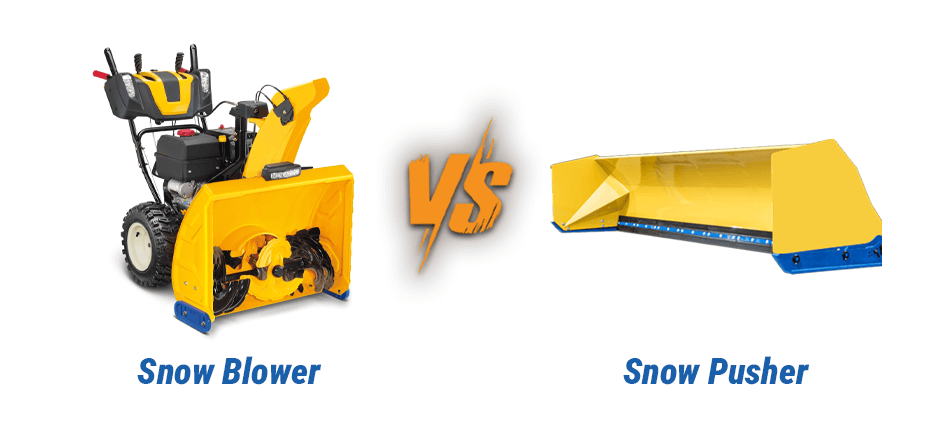

Winter work on off-road machines is rarely “just snow.” It’s traction, stacking space, visibility, surface protection, and how fast we can reopen lanes without beating up the equipment. In this guide, we’ll compare a snow blower and a snow pusher, the way equipment owners actually use them—on loaders, skid steers, and tractors—so we can pick the right tool for our site, our snow type, and our downtime tolerance.

What is a Snow Pusher?

A snow pusher (often called a box-style pusher) is a containment attachment designed to move snow by pushing it forward. Instead of throwing snow away from the travel path, it captures and carries a growing pile between side walls while we push to a stacking area.

How it works (in plain terms):

- A wide cutting edge contacts the surface and starts the roll of snow.

- Side plates keep snow from spilling off the ends.

- We push the contained snow to a pile, windrow, or a designated dump zone.

Why off-road machinery owners use it:

- It’s fast for open areas like lots, yards, and wide lanes.

- It has fewer moving parts than a blower, so it’s usually easier to keep running.

- It’s predictable: if the machine can push and maintain traction, the job gets done.

Where a snow pusher struggles:

- When there’s nowhere left to stack snow.

- In tight areas where we can’t build speed or turn wide.

- When snow is already piled high and frozen into berms (a pusher will move it, but the machine may fight traction and steering).

What is a Snow Blower?

A snow blower attachment removes snow by feeding it into an auger/impeller system and discharging it through a chute. Instead of pushing snow to the side and building banks, we relocate snow by throwing it into a controlled area.

How it works (typical attachment layout):

- The auger gathers snow and moves it toward the center.

- The impeller accelerates snow and pushes it out of the chute.

- The chute lets us control discharge direction to avoid burying curbs, doors, or cleared paths.

Why off-road machinery owners choose a blower:

- It solves the “no stacking space” problem by moving snow farther away.

- It can cut into plow windrows and drifted snow without needing a long run-up.

- It often leaves a cleaner path with less carry-back at edges (site conditions still matter).

Where a snow blower struggles:

- More moving parts mean more wear items and more checks.

- Debris (rocks, chunks of ice, frozen newspapers, pallets, splinters) can jam or break components.

- On gravel or uneven ground, we must manage cutting height and technique to avoid picking up stones.

Snow Blower vs. Snow Pusher

Both tools clear snow, but they clear it in different ways. The right choice depends less on “which is stronger” and more on where the snow can go and how often we clear it.

Quick comparison table

| Category | Snow Pusher | Snow Blower |

|---|---|---|

| Main action | Push and contain the snow | Collect and throw snow |

| Best when | Open space, long pushes, easy stacking | Limited storage space, deep drifts, precision cleanup |

| Snow relocation | Builds piles/banks on site | Can move snow away from site edges (via throwing) |

| Risk profile | Traction loss, curb impacts, cutting-edge wear | Jams, shear hardware failures, belt/drive wear, chute clogging |

| Maintenance style | Mostly edge/shoes/structure checks | More frequent inspection of the auger/impeller area and wear parts |

| Operator focus | Keep load centered, avoid overload, plan stacking | Control chute direction, manage feed rate, and avoid debris ingestion |

If we can push to a stacking zone without boxing ourselves in, a snow pusher usually clears faster per pass. If snow banks are already choking the site—or we must keep edges tight and open—a snow blower often keeps the whole operation from slowing down halfway through winter.

Factors That Determine Which to Use

Here’s the decision logic we rely on when picking between a snow blower and a snow pusher for off-road machines. These are the factors that have the most significant impact on outcomes.

1) Snow storage space

If our lot, yard, or access road has plenty of safe stacking room, pushing works all season. If not, a pusher can create its own problem: banks keep growing until sightlines shrink, doors get blocked, and melt-refreeze turns edges into hard berms.

A blower is often the “space-maker” because it throws snow beyond the immediate work zone and reduces bank growth—especially useful when we must keep traffic lanes wide and safe.

2) Surface type and debris risk

- Paved surfaces: Both work well. A blower can leave a cleaner finish, but we must keep the intake at the right height to avoid catching raised edges, drain grates, or broken pavement.

- Gravel / uneven surfaces: Pushers can be easier to control because we’re not feeding rocks into an impeller. A blower can still work, but we need careful setup (skid shoes/cutting height) and slower technique.

3) Snow type and timing

- Fresh, light snow cleared early: a pusher is usually quick and low-drama.

- Heavy, drifted, or windrowed snow: a blower can reduce the “wall effect” that stops pushers and forces repeated back-and-forth.

4) Machine capability and hydraulics/PTO match

A pusher is mostly about traction and pushing power. A blower is primarily concerned with delivering power to the attachment (hydraulic flow or PTO) and maintaining consistent RPM.

If the power source can’t keep the blower fed, productivity drops, and clogging risk goes up. If the machine can’t maintain traction with a loaded pusher, we’ll spin and waste time.

5) Downtime tolerance and maintenance habits

Pushers are mechanically simple. Blowers are still reliable when maintained, but they have more wear items that we must inspect and stock.

From the FridayParts snow blower guidance, common issues we see on blowers include:

- Auger not rotating (often related to a broken shear pin or a loose/slipping belt)

- Strange noises (loose parts or debris stuck in the auger area)

- Short throw distance (commonly a clogged chute or a worn impeller)

Those symptoms translate directly to attachment operations: if we ignore the early signs, a small issue becomes a job-stopper during the next storm.

Mid-Season Reliability: Parts Planning

Once we choose the tool, the next problem is staying operational when everyone else is also trying to buy parts. This is where we recommend planning around common failure points—especially for snow blower attachments.

Smart items to stock for a snow blower setup:

- Shear pins/shear bolts (they are designed to fail to protect drivetrain components)

- Auger belts (for belt-driven designs)

- Skid shoes (to control cutting height and protect the housing)

- Wear hardware and common fasteners for chute and guard areas

If we’re ordering ahead, it helps to use a supplier that shows clear product photos and broad compatibility across equipment lines. For a dedicated selection, we can browse snow blower parts and keep the common wear items on the shelf before the next storm locks everything up.

Conclusion

A snow pusher is often the fastest choice when we have room to stack snow and want simple, low-maintenance clearing. A snow blower earns its place when snow storage is tight, drifts are heavy, and we need controlled relocation instead of bigger banks. If winter uptime matters, stocking common wear items early is part of the plan. As an aftermarket parts supplier, FridayParts supports that plan with high-quality products at affordable prices, a vast inventory, and wide compatibility for many heavy equipment brands.