Selecting a new combine harvester stands among the most perilous decisions faced by contemporary farmers. The combine harvesters constitute the very nucleus of harvesting operations, their performance exerting a direct influence upon your profitability, efficiency, and degree of exertion during the most crucial weeks of the year. With the market overwhelmed by a multitude of sophisticated models and contending technologies, to sift through the dazzling promotional rhetoric and discern the machine truly befitting your farm proves far from an effortless task. We are devoted to the resolution of this dilemma. This guide shall elucidate the 5 best combine harvesters of 2025, examining their principal merits, innovative attributes, and ideal applications, so that you may render a judicious and well-grounded investment.

Key Points to Consider

- Throughput vs. Grain Quality: Certain combine harvesters lay great emphasis upon velocity and output, whilst others demonstrate superiority in delivering purer grain samples with minimal impairment. It is of consequence to discern which element bears greater significance to your operation and the crops you cultivate.

- Simplicity and Serviceability: A machine that is more amenable to upkeep and possesses fewer points of attrition signifies diminished downtime during the most critical harvest intervals. It would be prudent to contemplate the machine’s construction, as well as the accessibility of dependable components and service.

- Performance in Your Conditions: A combine that exhibits remarkable efficiency amidst level and arid cornfields may not necessarily render itself suitable upon undulating hills or upon stalks both tenacious and moist. Therefore, one ought to deliberate upon the customary conditions of one’s fields and the types of crops therein.

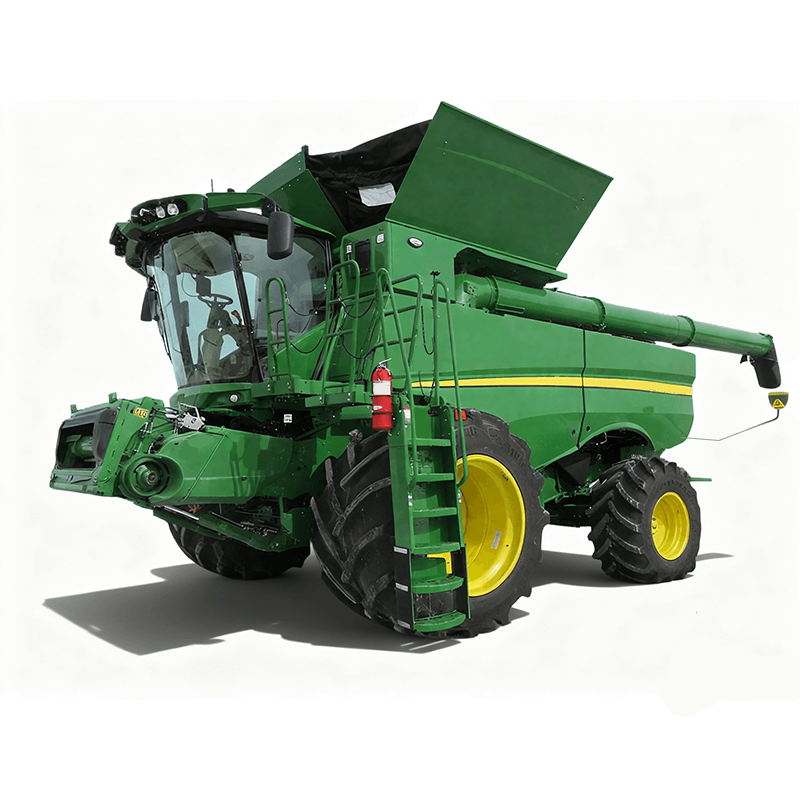

Top1: John Deere S780 (No. 1 in US sales)

The John Deere S780 has solidified its place as one of the best John Deere combine harvesters models by focusing on intelligent automation. It’s designed for the operator who wants to leverage cutting-edge technology to optimize performance automatically. This machine is less about manual tweaking and more about letting the combine’s brain do the heavy lifting to maintain peak efficiency as conditions change throughout the day.

Key Features & Benefits:

- Automated Combine Advisor™: This is the S780’s standout feature. It uses a system of cameras and sensors to monitor the tailings and clean grain, then automatically adjusts the five core combine settings to maintain your pre-set targets for grain loss and quality. This means less time spent making manual adjustments and more consistent performance.

- Increased Threshing Capacity: By the adoption of the Active Concave Isolation (ACI) technology, the concaves are hydraulically suspended. This allows improvement of yield while handling small-grain crops and rice, which are difficult to thresh, without increasing grain losses, thus effectively prolonging your harvesting duration.

- Intuitive Operator Controls: The 4th Generation CommandCenter display is a common feature among the large equipment series of John Deere. This familiar application-based touch screen interface is easy to navigate and customize, shortening the learning curve, making any operator able to monitor the crucial functions effortlessly.

Specifications at a Glance:

| Feature | John Deere S780 |

|---|---|

| Engine Power | 473 hp (with 50 hp boost) |

| Grain Tank Capacity | 400 bu (14,100 L) |

| Rotor Type | Single Rotor (TriStream™ or Variable Stream) |

| Emission Level | Tier 2 / Tier 4 Final options |

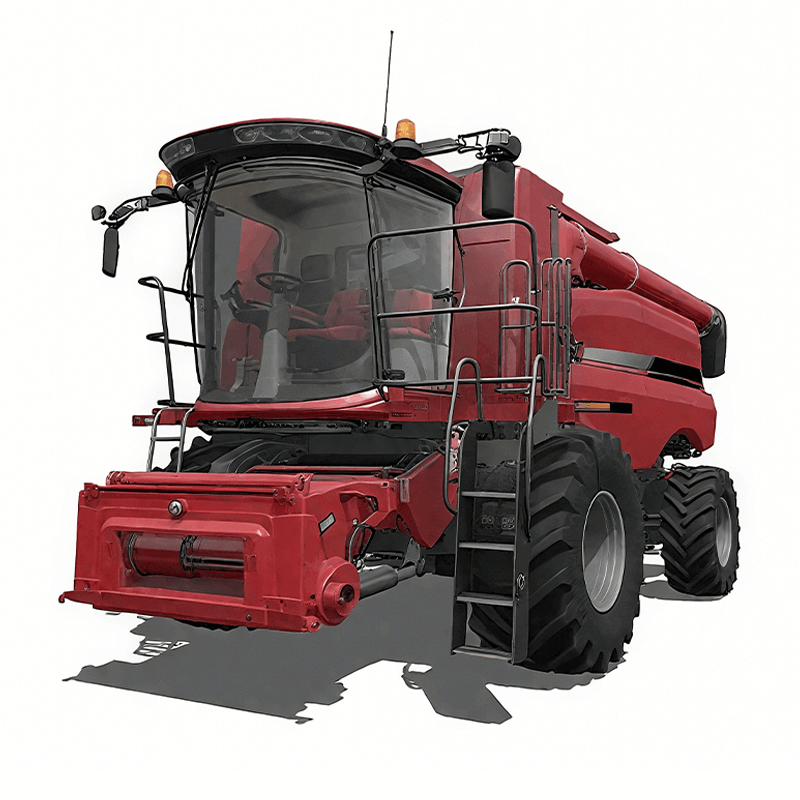

Top2: Case IH Axial‑Flow 8250

Among the preeminent marques of best combine harvesters, CASE stands as the very epitome of the single-rotor axial-flow configuration, and the 8250 model serves as the paragon of its enduring vigor and simplicity of operation. This combine harvester is conceived expressly for high-capacity and convenient harvesting. Its design philosophy revolves around a more efficient material flow and a reduction in moving components, thereby achieving superior grain quality while simplifying maintenance.

Key Features & Benefits:

- Proven Axial-Flow Threshing: The single-rotor structure performs repeated threshing through a spiral motion. This gentle grain-to-grain separation method has gained renown for producing the cleanest and finest grain samples within the industry, while maintaining an exceedingly low breakage rate.

- High-Capacity Feeding: The 8250 is architected to convey massive crop material smoothly from the header to the rotor. Such efficient feeding is of paramount significance for maximizing horsepower and sustaining elevated ground speed, particularly under heavy residue conditions.

- Fast Unloading: With a 410-bushel grain tank and an unloading rate of 4.5 bushels per second, the tank can be emptied within a mere two minutes. This minimizes idle time for both the combine harvesters and the grain carts, thus ensuring the entire harvesting operation proceeds with utmost efficiency.

Specifications at a Glance:

| Feature | Case IH Axial-Flow 8250 |

|---|---|

| Engine Power | 555 max hp |

| Grain Tank Capacity | 410 bu (14,448 L) |

| Rotor Type | Single Axial Rotor |

| Total Sieve Area | 10,330 sq. in. |

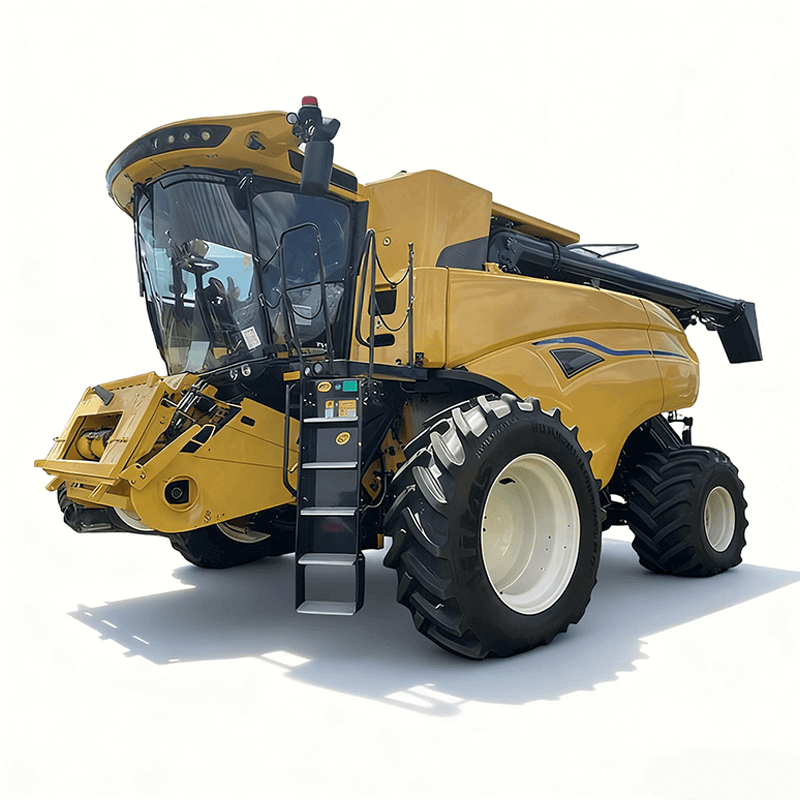

Top 3: New Holland CR8.90 Revelation

When the primary goal is to cover as many acres as possible in a day, the New Holland CR series is a dominant force. The CR8.90 Revelation is a direct beneficiary of the technology that set world records for harvesting both wheat and soybeans. It is engineered from the ground up for maximum throughput and productivity, making it ideal for large-scale farming operations where time is money.

Key Features & Benefits:

- Unmatched Throughput with Twin Rotor® Tech: Instead of one rotor, the CR series uses two smaller, more efficient rotors. This provides a huge threshing and separation area, allowing the machine to process an incredible volume of crop material while maintaining gentle, multi-pass action for low grain damage.

- IntelliSense™ Proactive Automation: This award-winning system goes a step beyond reactive adjustments. It uses data to predict and proactively change settings to optimize throughput, minimize losses, and ensure a clean sample, effectively giving the operator a “sixth sense” in the field.

- On-the-Go Adjustments: The Dynamic Flow Control™ system allows the operator to change the rotor vane position from the cab. This lets you instantly adapt to changing crop conditions, like tough straw in the morning versus dry straw in the afternoon, potentially boosting productivity by up to 20%.

Specifications at a Glance:

| Feature | New Holland CR8.90 Revelation |

|---|---|

| Engine Power | 517 max hp |

| Grain Tank Capacity | 355 bu (12,500 L) |

| Rotor Type | Twin Rotor® |

| Key Feature | IntelliSense™ Automation |

Top 4: Gleaner S97

The Gleaner S97 stands out in the market with a fundamentally different design philosophy. It is built around a “Natural Flow™” process, which provides a more direct and efficient path for the crop through the machine. This results in a reduction of horsepower requirements, a decrease in fuel consumption, and a mitigation of the machine’s overall mass. The sustained optimum performance of any combine harvesters is contingent upon the continual provision of high-quality harvester parts, and a more simplified design customarily signifies a lesser quantity of wear points demanding supervision.

Key Features & Benefits:

- Efficient Natural Flow™ Design: Unlike transverse rotor systems, the Gleaner’s rotor is oriented longitudinally. The crop is fed directly into the front of the rotor and processed in a straight line, which requires less energy to move the material through the machine.

- Reduced Compaction: The S97 is known for being one of the lightest Class 7 combines on the market. This lighter footprint means less soil compaction, which is critical for maintaining soil health and maximizing yields in subsequent seasons.

- Operator-Focused Vision™ Cab: The cab is designed for comfort and visibility, with a large glass area and an intuitive Tyton™ terminal. This powerful display makes it easy to monitor machine performance and make real-time adjustments to maximize efficiency.

Specifications at a Glance:

| Feature | Gleaner S97 |

|---|---|

| Engine Power | 375 hp (with 439 hp boost) |

| Grain Tank Capacity | 390 bu (13,743 L) |

| Rotor Type | Natural Flow™ Single Rotor |

| Key Feature | Lightweight and efficient design |

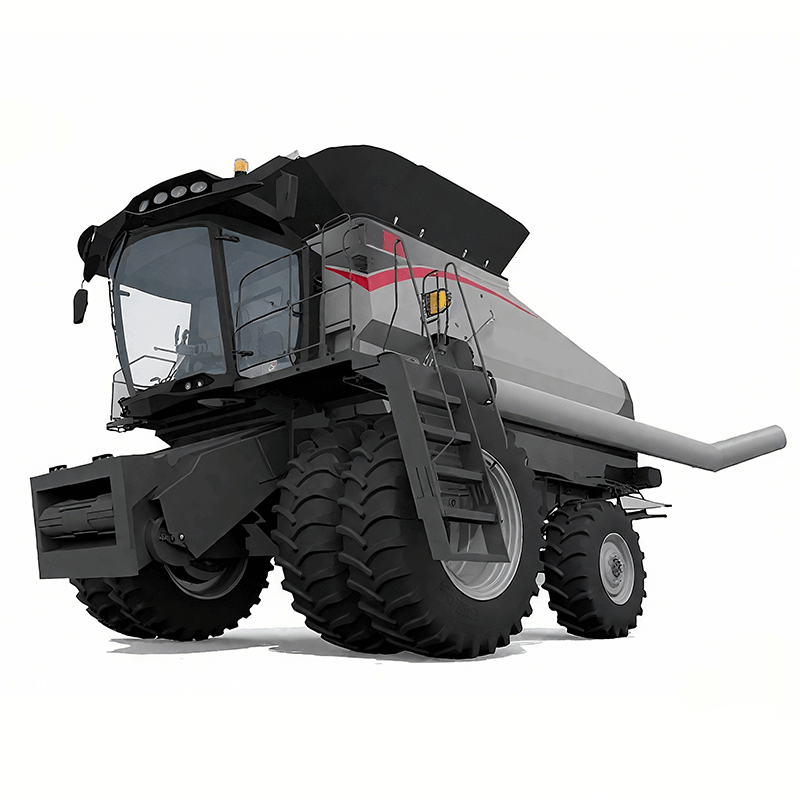

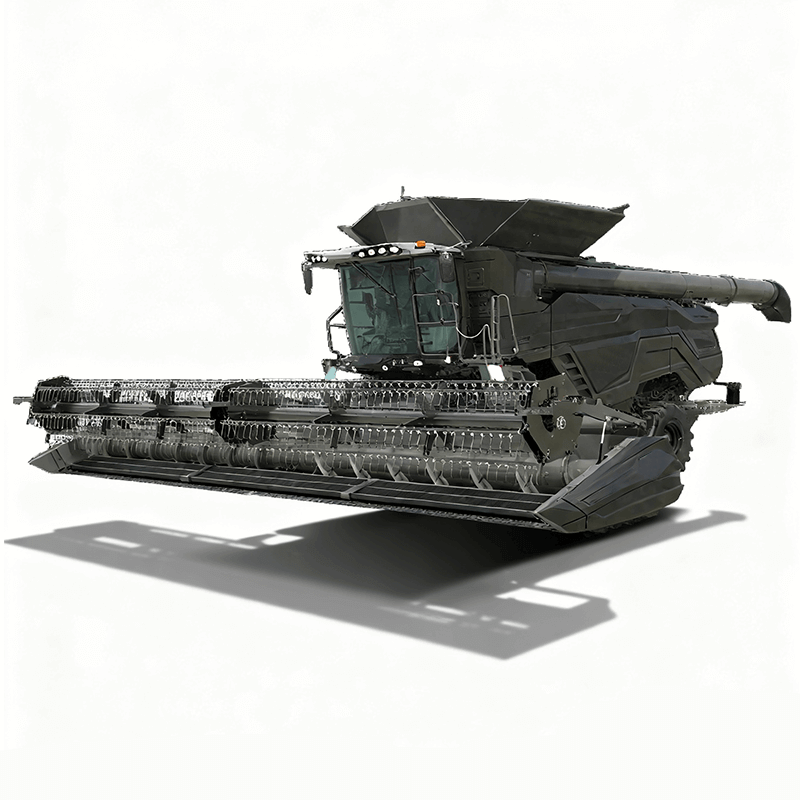

Top 5: Massey Ferguson IDEAL 9

The Massey Ferguson IDEAL is a machine with several truly innovative features designed to solve common harvesting challenges. The IDEAL 9 is for the forward-thinking farmer who wants the latest technology for performance, especially in challenging terrain.

Key Features & Benefits:

- Superior Performance on Slopes: The IDEALbalance™ system is a game-changer for anyone farming on hills. It uses two specially shaped grain pans under the rotor that distribute crop material evenly to the cleaning shoe, even on slopes up to 15%. This drastically reduces losses when harvesting on sidehills.

- High-Capacity, Gentle Threshing: The “Dual Helix” processor provides a massive threshing area with a design that is powerful yet gentle on the grain and straw. It’s designed for high capacity without sacrificing the quality of the final product.

- Reduced Maintenance: The IDEAL features a very simple “DriveCenter” gearbox that powers all main components. This design uses a minimal number of belts and chains, resulting in greater fuel efficiency, quieter operation, and fewer parts to service and replace.

Specifications at a Glance:

| Feature | Massey Ferguson IDEAL 9 |

|---|---|

| Engine Power | 647 hp |

| Grain Tank Capacity | 485 bu (17,100 L) |

| Rotor Type | Dual Helix Processor |

| Key Feature | IDEALbalance™ for slope compensation |

FAQs

Q1: What is the main difference between a single-rotor and a twin-rotor combine?

A single-rotor combine (like Case IH and Gleaner) uses one large rotor for threshing and separation. A twin-rotor combine (like New Holland) uses two smaller rotors. Generally, twin-rotor designs can offer higher capacity, while single-rotor designs are often praised for their simplicity and grain quality.

Q2: How much does a new combine harvester cost?

The price of a new combine varies dramatically based on brand, class size, and options, but you can generally expect a new, well-equipped machine from this list to range from $500,000 to over $900,000 USD. The final price depends heavily on the header, technology packages, and track or tire options selected.

Q3: How do I choose the right size (class) of combine for my farm?

Combine classes are loosely based on horsepower. The right class for you depends on your total acreage, typical crop yields, and desired harvest window. A good rule of thumb is to choose a machine that can comfortably harvest your entire crop within 10-14 good weather days.

Keeping Your Investment Running

An excellent combine harvester is the one most suitable corresponding to your cultivated land area, crop type, and operational manner. Whether your foremost consideration lies in John Deere’s intelligent automation, New Holland’s original capacity, or Gleaner’s efficient construction, these machines constitute a substantial investment. To attain ideal preparation for the autumn harvest, it is necessary to acquaint yourself with the prevailing brands and models in the market and select the combine harvester most harmonized with your undertaking. If you already own a combine and simply need repairs for the fall harvest, FridayParts aftermarket parts are a great choice. We possess reliable and superior-quality components that assist you in minimizing downtime to the greatest extent and effectively administering long-term operational expenditures.