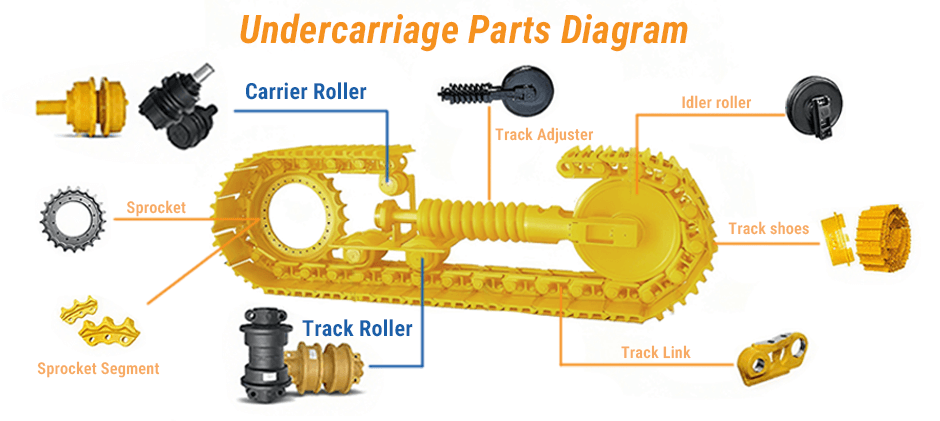

For the crawler-type heavy machinery, the undercarriage system is regarded as the very foundation of productivity, whilst simultaneously occupying a voluminous proportion within the expenditure of maintenance. Amidst such a system of labyrinthine complexity, there reside two constituents often confused yet of utterly divergent utility: the track roller and the carrier roller. To apprehend the disparity between roller and carrier roller is not a mere matter of technical acquaintance; rather, it is of paramount consequence for the rectitude of maintenance, the timeliness of replacement, and the ultimate circumvention of premature attrition and calamitous malfunction. This present guide shall proffer a most comprehensive juxtaposition, that you may with precision discern those particulars demanding heed and thus preserve the machinery in a state of unruffled operation.

What are Track Rollers and Carrier Rollers?

At a glance, they might just look like wheels within the track system, but their location and function are completely different. Let’s define each one clearly.

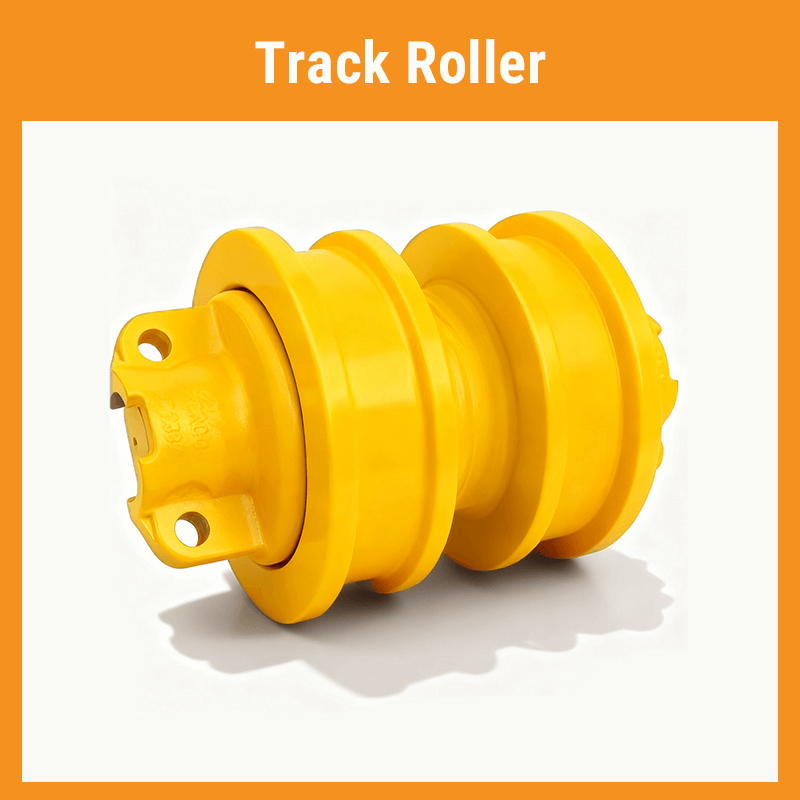

What are Track Rollers?

Track rollers, also commonly called bottom rollers or lower rollers, are the workhorses of the undercarriage. They are a series of wheels located on the bottom of the track frame.

- They Support the Machine’s Weight: Their primary job is to bear the entire weight of your excavator or dozer and transfer it to the tracks, and then to the ground.

- They Guide the Track: They run along the track chain’s rail, guiding the machine and keeping the track from moving side-to-side.

- They Handle the Terrain: Because they are on the bottom, they are in constant contact with the track that rolls over rocks, mud, and uneven ground, meaning they must absorb immense shock and impact.

- They Are Numerous: A machine will have many track rollers (typically 5-9 per side on mid-to-large machines) to evenly distribute the massive load.

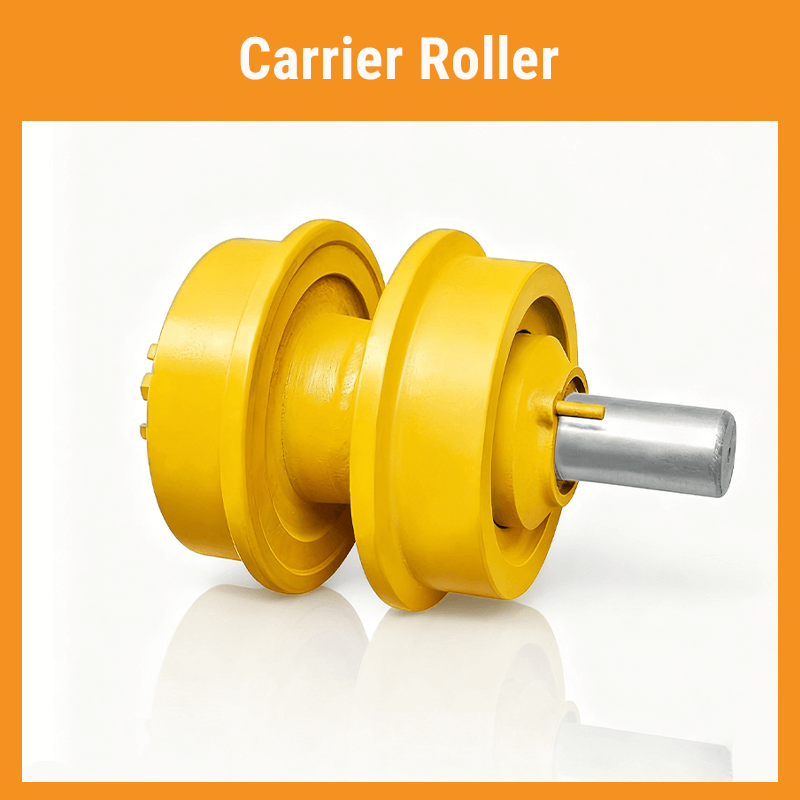

What are Carrier Rollers?

Carrier rollers, also known as top rollers or upper rollers, are located on the top of the track frame. Not all machines have them, especially smaller mini-excavators, but on larger equipment, they are crucial.

- They Support the Track Chain: Their sole purpose is to support the weight of the track chain as it travels along the top from the sprocket to the front idler.

- They Prevent Sagging: Without carrier rollers, the long, heavy upper portion of the track would sag significantly, which could cause it to slap against the frame, creating noise, vibration, and excessive wear.

- They Guide the Upper Track: They help ensure the track chain feeds smoothly and correctly into the drive sprocket.

- They Are Few: A machine will typically have only one or two carrier rollers per side, as the load they carry (just the track) is significantly lighter.

Track Roller vs Carrier Roller: The Main Difference

While both are types of rollers, considering them interchangeable is a critical mistake. Their differences in location, function, and design are what define their roles in the undercarriage. Let’s break down the main differences in a way that’s easy to visualize.

1. Location & Ground Contact

This is the easiest way to tell them apart.

- Track Rollers (Bottom): Are located on the bottom of the undercarriage frame. They do not touch the ground directly, but they are in constant, high-pressure contact with the section of the track that is in contact with the ground.

- Carrier Rollers (Top): Are located on the top of the frame. They have zero contact with the ground and only touch the inner side of the upper track chain.

2. Primary Function & Load

This is the most important functional difference.

- Track Rollers are for WEIGHT-BEARING. They support the entire multi-ton weight of the machine plus any load it’s carrying. They are a primary structural support component.

- Carrier Rollers are for GUIDANCE. They only support the weight of the track chain itself (a few hundred pounds) to keep it from sagging. Their role is alignment, not heavy support.

3. Design & Construction

Their jobs dictate how they are built.

- Track Rollers are built for brute force. They are thick, heavy, and feature robust single or double flanges (lips) to keep the heavy track chain aligned under immense pressure. They are made from forged, high-carbon steel and are heat-treated to withstand extreme abrasion and impact.

- Carrier Rollers are built for smooth rolling. They are generally smaller, lighter, and have a simpler, flatter wheel profile. Since they don’t handle high impact, their design is focused on reliable rotation and guiding the track.

Here is a simple table to summarize the key distinctions:

| Feature | Track Roller (Bottom Roller) | Carrier Roller (Top Roller) |

|---|---|---|

| Location | Bottom of the track frame | Top of the track frame |

| Primary Job | Support the entire machine’s weight | Support the upper track chain to prevent sag |

| Load Type | Extreme, high-impact (tons of force) | Light, consistent (weight of the track only) |

| Quantity | Many (5-9 per side) | Few (1-2 per side, or none) |

| Design | Heavy-duty, thick, with large flanges | Lighter, smaller, with a simpler profile |

Which Should You Choose?

You need not choose between the track carrier roller and the idler; your machine has been designed for a specific configuration. The true selection arises only when replacement parts are required. Here are the considerations to ponder:

- Machine Compatibility: This is indisputable. Carrier rollers must correspond fully with your machine’s brand, model, and serial number to ensure proper fitting and normal operation.

- Flange Type (for Track Rollers): Track carrier rollers possess single-flange and double-flange designs. Double-flange rollers provide maximal guidance, commonly employed at the front, rear, and lateral positions of the sprocket. Single-flange rollers are used at the middle positions. Employing an incorrect configuration may induce track wear.

- Material and Build Quality: Opt for carrier rollers fabricated from premium boron steel or carbon steel, duly heat-treated and surface-hardened for wear resistance. The quality of internal seals is equally crucial for maintaining lubrication and preventing ingress of dust. This is precisely why investing in high-quality undercarriage parts yields substantial returns.

When Should They Be Replaced?

Regular inspection is key. A worn-out roller can cause a domino effect of destruction on your undercarriage. Look for these clear signs of wear during your daily walk-arounds:

- Visible Oil Leakage: If you see oil seeping from a roller, its internal seals have failed. The bearings will soon run dry, and the roller will seize. This is a critical warning sign—replace it immediately.

- Flat Spots: As rollers wear, they can develop flat spots on their rolling surface. This creates a bumpy ride and puts uneven stress on the track links.

- Worn Flanges: The flanges are the “lips” that guide the track. If they are worn thin or have chunks broken off, the track can wander or even derail.

- Seized Rollers: Use a bar to check if each track roller and carrier roller spins freely when the track is lifted. A seized roller will act like a brake, grinding away at your track chain with every rotation.

Ignoring these signs is a costly mistake. A single failed roller can destroy a track chain worth thousands of dollars in a very short time.

Where Can You Find High-Quality Rollers?

The proactive caring of machines together with the timely changing of the worn-out components is regarded as the hidden secret for the enduring lastingness of undercarriage strength. Once the careful checking discloses the necessity for renewal, the dependable component shall guarantee the process of maintenance to move forward smoothly. At this very point, the reputable aftermarket provider FridayParts is turning into a partner of much value. By reason of the wide-stretched storage of high-standard rollers, you are to anticipate products with both durability and reliability, while still keeping the price within the range of affordability. As one companion possessing vast compatibility among many heavy equipment brands, FridayParts assures that the proper component will be reached at the moment of need, thus lessening the idle time and preserving the profitability of your operations.

Final Summary

In conclusion, although the track roller and the carrier roller look much alike in outward appearance, their role inside the undercarriage system of the machine are utterly not the same. The track roller is bearing the tremendous heaviness of the equipment, while the carrier roller is merely guiding the upper track chain. To be acquainted with their unique functions, the peculiar patterns of wearing, and to replace them in due moment, is of utmost necessity for the prolongation of the whole undercarriage system’s life, the lessening of costly halting time, and the securing of safe as well as efficient running of the heavy machinery.