A final drive is a key component in machinery like mini excavators and skid steers, responsible for moving the tracks by converting hydraulic power into torque. Bobcat, which is famous for its compact excavators and skid steers, has a high demand for an efficient final drive system. While a final drive motor is a key part of the final drive system, picking a compatible motor is crucial to keeping your bobcat running smoothly. But how to pick the best bobcat final drive motor? Here is an ultimate guide for you.

What Does Motor Do in Final Drive System?

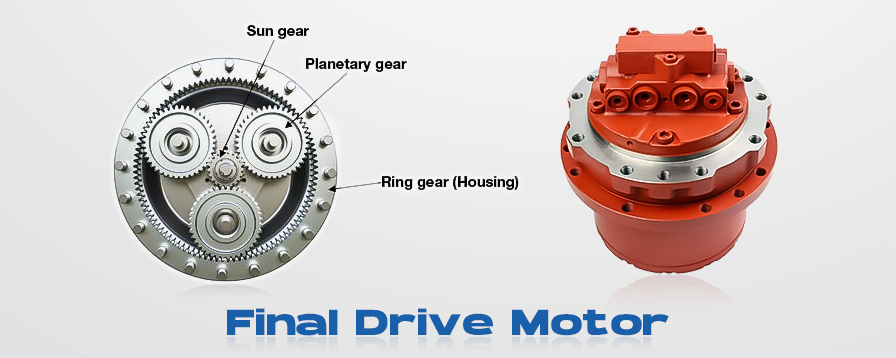

The final drive motor is a key part of the final drive system. It converts hydraulic power into mechanical power, which then powers the gears inside the final drive, specifically the planetary gear system. The motor’s role is to provide the torque necessary for the final drive to rotate the machine’s tracks, enabling movement. Both components work together, with the motor providing the force and the final drive managing speed and torque distribution. But as the service life increases, wear, damage, and aging happen, thus the final drive motor needs replacement.

Identify Model and Specification

When considering a bobcat final drive motor replacement, correctly identifying the model number and specifications is the first step. This usually involves checking the label or manual on the unit to determine the exact model number and required specifications. Sometimes, this information can also be found on Bobcat’s official website by looking up the serial number. If you are unsure how to identify the model number and specifications, consult a professional technician who could help.

Bobcat Final Drive Motor Performance Considerations

When selecting a Bobcat final drive motor replacement, performance is a key factor in determining its suitability for your equipment. Below are some important performance indicators and how they affect the performance of your equipment:

- Torque: Torque is a measure of the rotational force of a motor. For your bobcat equipment, sufficient torque is critical to ensure that the machine operates efficiently in a variety of operating conditions. If your equipment is often exposed to rough terrain or under heavy loads, a high-torque final drive motor is necessary. It could provide more traction and climbing ability.

- Speed: Besides torque, speed is the second important consideration when picking a final drive motor. The speed of the final drive motor determines how fast the equipment can travel. Choosing a motor with the right speed will ensure that the equipment maintains optimal efficiency in a variety of work scenarios. For example, for jobs that require fast movement, choosing a high-speed motor would be more appropriate.

- Durability & Reliability: Durability and reliability are two universal qualifications of bobcat final drive motor selection. Overall, the lifespan of a final drive motor typically ranges from 2,000 to 5,000 hours, depending on factors such as maintenance, usage conditions, and the quality of the motor itself. Choosing a motor with good durability ensures that the equipment will maintain consistent and reliable performance over a long period of time. Also, a well-known brand or a motor that has undergone strict quality control can increase its reliability.

- Maintenance requirements: Different final drive motors may have different maintenance requirements. Choosing a motor that is easy to maintain and has long maintenance intervals can reduce maintenance efforts and costs. FridayParts.com is an online shop that can perfectly meet the standards. If you are looking for a quality bobcat final drive motor replacement, don’t miss FridayParts. Our final drive motors are made of durable materials and can perfectly meet high-demanding torque and speed requirements.

Bobcat Final Drive Motor Maintenance Tips

To ensure the long-term performance and longevity of your new motor, there are several maintenance tips to follow. Inspect the motor regularly to look for any damage or leaks. Remember to keep the motor clean to prevent wear caused by contaminants. What’s more, make sure all parts are proper and tightened according to the manufacturer’s recommendations (or Bobcat Official). In addition, monitor the motor’s performance, such as noise and vibration, which can be early signs of potential problems. Finally, it’s always a good idea to take maintenance guidelines provided by Bobcat or the motor manufacturer and seek professional technical service when needed. With these simple steps, you can maximize the efficiency and durability of your new final drive motor.

Conclusion

In conclusion, choosing the right replacement for your Bobcat final drive motor is a critical decision that can significantly impact the performance, reliability, and longevity of your equipment. By considering the factors we’ve discussed—such as understanding the role of the final drive motor, identifying the correct model and specifications, and evaluating performance metrics, you can make an informed choice. For more professional guidance and quality goods, FridayParts is here to help.