Boom lifts haul workers and materials up and out, getting them to those tricky, hard-to-reach spots for high-place jobs. The two most popular kinds are articulating boom lifts and telescopic boom lifts—both have hydraulic arms that can reach pretty far. You will likely see a boom lift on a construction site. They are used for interior and outdoor tasks, including painting, window washing, roofing, and more. In this article, we will talk about 3 types of boom lifts and what they do.

What Is a Boom Lift?

The boom lift is a type of aerial work platform that uses a hydraulic arm to lift a basket or platform holding workers and their tools. Unlike scissor lifts, which only move straight up and down, boom lifts can reach both up and out—so they’re way more versatile. These machines are attached to a movable base, and they can run on diesel engines for tough outdoor ground, or electric motors for quiet, zero-emission indoor jobs. With choices like two- or four-wheel drive, plus different tire or track setups, there’s a boom lift made for almost any spot—whether it’s smooth concrete floors or muddy, bumpy construction sites.

What Types of Boom Lifts Are Available?

There are all kinds of boom lifts out there, but they have three main types. Knowing the basic design of each one is key to picking the right machine for the job.

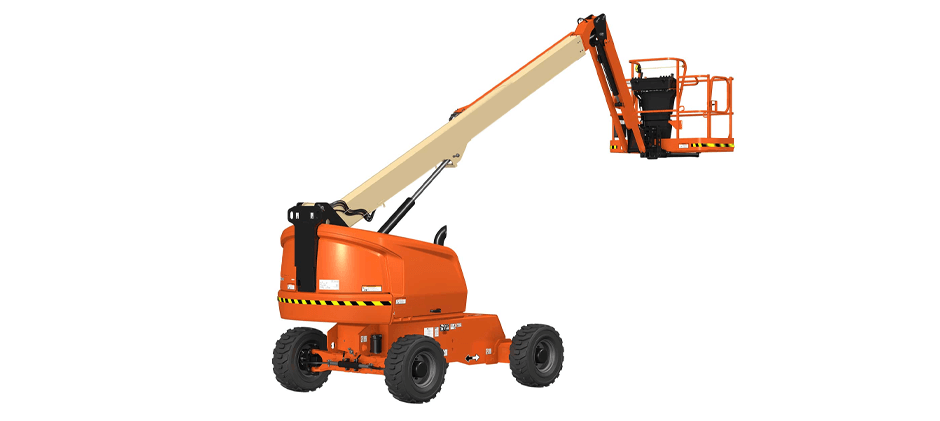

Telescopic Boom Lifts

People often call these stick booms or straight booms. They have a single straight arm that stretches out just like a telescope. This design is all about maxing out reach. The boom sections slide out from inside each other to extend farther. The whole arm is fixed on a rotating turntable, so it can spin a full 360 degrees.

Nothing beats their horizontal and vertical reach. If you just need to get as high or as far out as possible, a telescopic boom lift is the way to go. Most regular models can reach 40 to 80 feet high. The biggest ones? They can go over 180 feet up.

These lifts are perfect for jobs in open spaces where you’ve got a clear shot to the work area. Think high-rise window cleaning, bridge checks, big painting projects, and maintenance work on tall industrial structures. Since they extend straight out, they’re usually quicker to position at super high heights than articulating boom lifts.

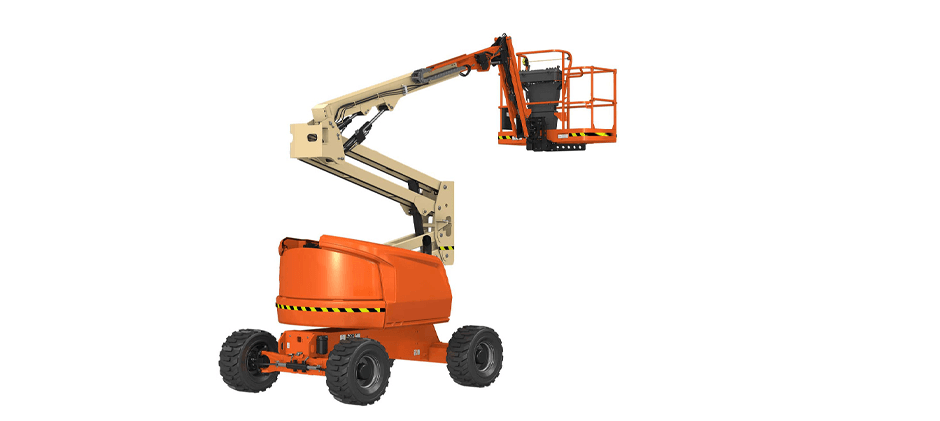

Articulating Boom Lifts

People also call these knuckle booms. They’re easy to spot thanks to their multi-jointed arms. The boom bends at several spots—we call these “knuckles”—and that’s what makes it super flexible. Each part of the boom can be angled on its own. Operators can move the platform around obstacles, whether those obstacles are on the ground or up in the air. These lifts don’t reach as far horizontally as a telescopic boom of the same size, but their agility is totally unbeatable.

The best thing about an articulating boom is its “up-and-over” ability. It can reach over obstacles, twist around corners, and get into tight, crowded spots that a straight boom could never touch.

These lifts are made for tricky job sites with lots of stuff in the way. Think electrical work in a packed factory, plumbing fixes around existing pipe racks, or tree trimming over a building. A lot of models also have zero or barely any tail swing. That makes them perfect for working in narrow aisles or between buildings.

Atrium Lifts (Spider Lifts)

Atrium lifts are a specialized type built for unique, tough jobs. You can spot them right away—they’ve got a compact base and four spider-like legs (we call these outriggers).

Most atrium lifts use tracks instead of wheels. The benefits are direct: the weight is spread out and it is not easy to crush the ground. So whether it is grass, sidewalk, or even an indoor marble floor, it can be used with greater confidence. Just spread out the four legs before work and the machine can stand firmly. Even if the ground is a little inclined or uneven, it can maintain good stability and make it more secure to use.

They’re way lighter and narrower than regular boom lifts. That means they can fit through standard doorways and work in places with strict floor weight limits—like atriums, malls, or churches. These lifts are perfect for indoor and outdoor jobs that need height but have tight spaces or delicate surfaces. Their tracked design also makes them great for navigating rough, uneven ground—places where wheeled machines would get stuck.

What Type of Boom Lift Do You Need?

To choose the right boom lift, first look at what exactly is needed on the construction site. Thinking through the following questions, you will basically know which arm lift to choose.

- How high and far should we go? This is the first thing to consider. First, measure the maximum height and horizontal distance required. If the main pursuit is “reaching far” and there are no obstacles ahead, a telescopic boom lift is most suitable.

- Are there any obstacles on site? If you need to work over equipment, eaves or other obstacles, you have to rely on more flexible models such as articulated arm lifts.

- For indoor or outdoor use? If the outdoor area and the ground are not too flat, a diesel four-wheel drive arm lift is generally used. If you are working indoors, use an electric lift, which has no exhaust and is easier to operate in a small space.

- What are the ground conditions like? Is it a flat cement field, a mud field, or sloping grass? This will determine whether you use non-marking tires, off-road tires, or a crawler lift with low ground pressure.

- Is there a lot of space on site? Telescopic arm lifts have a larger turning radius and require more space. If the place is narrow, the small body and zero tail swing of the articulated arm lift are important. If space is particularly limited, a crawler lift may be the only option.

What Options and Accessories Do You Need?

Besides picking the right basic lift type, you can add all sorts of extras to boost safety and get work done faster.

- Jib arm: This is a small, extra-bendy section at the very end of the main boom. It adds one more moving part, so you can position the platform super precisely—no need to move the whole machine around.

- Non-marking tires: If you’re working indoors on polished floors, these special tires won’t leave those annoying black scuff marks behind.

- Platform work lights: Total must-have for jobs that run late into the evening, or for dimly lit indoor spaces.

- Racks and trays: For specific trades, you can mount things like pipe racks or panel trays on the platform railings. These hold your materials securely and out of the way, freeing up space in the basket and making the job safer.

Boom Lift Safety Tips

Using any aerial lift comes with built-in risks. The most dangerous part of using a boom lift isn’t when you’re at full height. It’s that sudden jolt from a tiny bump on the ground. That bounce gets amplified as it travels up the boom, and it can easily fling a worker who isn’t strapped in right off the platform.

- Always wear a well-fitted harness: OSHA says you need a personal fall arrest system (a harness plus a lanyard) on a boom lift. The harness should be snug—you shouldn’t be able to slip a hand between the strap and your body.

- Check your tie-off points: Before clipping yourself in, take a look at the anchor points inside the basket. Make sure the welds are solid and don’t have any cracks.

- Inspect the basket floor: Check for cracks, tears in the mesh, or any other damage before you step in.

- Stay far away from power lines: Keep a safe distance from all electrical sources. The general rule is to stay at least 15 feet away from power lines.

- Don’t mess with safety features: If the lift’s tilt sensor stops you from raising the boom, it’s because the machine is on uneven ground. Don’t try to prop it up with random stuff like planks or blocks to level it. Move the lift to a flatter, more stable spot and reset it.

In Conclusion

Telescopic booms reach the farthest, articulating booms weave around obstacles like a pro, and atrium lifts get you into tight spots or onto delicate surfaces without a hitch. Whether you’re doing repairs or cleaning, aerial work platforms (AWPs) give you more height options and are way safer than old-school gear. But remember—AWPs need regular checks and maintenance. If you’re looking to replace or upgrade parts, FridayParts has what you need. We stock tons of compatible aftermarket parts, from telescopic boom lift bits to spider lift components. And with our OEM-quality guarantee and one-year warranty, it’s no wonder customers keep coming back to us.