Compared to other heavy equipment brands such as Komatsu, CASE, or Caterpillar, the JLG is a rather young brand. JLG Industries was founded in 1969, and a year later, JLG introduced the world’s first commercially produced aerial work platform (AWP), and a leading giant was born. JLG provides essential machinery like boom lifts, scissor lifts, and telehandlers to various industries. This powerful equipment works hard, often in demanding environments. To keep them operating safely and efficiently, regular maintenance and timely replacement of worn or faulty parts are crucial.

Knowing which JLG parts are most likely to need attention can help operators and maintenance teams stay ahead and ensure a longer lifespan. This article explores the most common JLG parts that require replacement, offering practical insights for JLG heavy machinery operators.

Also read: How Can I Find the Right JLG Parts for My Machine?

Why Do JLG Parts Need Replacement?

As long as you are using the machinery, your JLG is experiencing wear and tear. There are several factors that could contribute to the equipment’s aging, including friction, stress, and fatigue of moving parts. Besides daily operational wear, other elements include:

- Operating Environment: Machines used in harsh conditions, such as extreme temperatures, dusty sites, or corrosive atmospheres, will likely see parts degrade faster.

- Intensity of Use: Equipment that is used for more hours per day or frequently operates at its maximum load capacity will naturally experience accelerated wear on certain components.

- Maintenance Practices: Adhering to a proactive JLG maintenance schedule, which includes regular inspections and preventive replacements, is key. Reactive maintenance, where parts are only replaced after failure, can lead to more extensive damage and costly downtime.

- Age of Equipment: Older machines, even with good care, will inevitably require more JLG replacement parts as components reach the end of their service life.

Identifying worn parts early through diligent inspection is a cornerstone of effective JLG equipment management.

Key Categories of Commonly Replaced JLG Parts

Understanding the types of parts that most frequently need changing can help in planning maintenance schedules and managing inventory.

Summary Table

| Part Category | Common Parts | Symptoms of Failure / Wear Indicators | Importance for Operation |

|---|---|---|---|

| JLG Wear Parts | Tires, Bushings, Bearings, Wear Pads, Decals | Visible wear, cracks, tears, excessive play in joints, noise, illegible labels | High (Safety & Function) |

| Hydraulic System | Hoses, Fittings, O-rings and seals, Filters, Pumps, Cylinders | Leaks, slow/jerky operation, loss of power, system overheating, unusual noises | Critical |

| Electrical System | Batteries, Ignition Switch, Joystick Controller, Wiring Harness, Sensors, Safety Switches | No start, intermittent operation, faulty controls, error codes, dim lights | Critical |

| Engine (if applicable) | Filters (Oil, Fuel, Air), Spark Plugs, Glow Plugs, Belts, Throttle Cable | Poor engine performance, starting issues, unusual noises, visible wear/cracks | High (Function) |

| Platform Components | Foot Switches, Control Box Buttons/Switches | Unresponsive controls, physical damage, and sticking buttons | High (Safety & Control) |

1. JLG Wear Parts – The Frontline of Operational Stress

These JLG wear parts are designed to handle direct operational stresses and are often the first to show signs of needing replacement.

- Tires and Wheels: Essential for mobility, tires on JLG scissor lift parts and JLG boom lift parts are in constant contact with various surfaces. They are susceptible to punctures, cuts, and general wear. Different job sites may require different tire types, and ensuring they are in good condition is vital for safety and stability.

- Bushings and Bearings: Found in numerous pivot points, such as boom sections, scissor arm linkages, and steering mechanisms. These components allow for smooth movement. As they wear, they can cause excessive play, noise, and instability in the lift’s operation.

- Wear Pads: Particularly crucial for JLG boom lift parts, wear pads are typically made from materials like nylon or UHMW plastic. They sit between extendable boom sections, reducing friction and ensuring smooth extension and retraction. Over time, these pads wear down and require replacement to prevent damage to the boom sections themselves.

- Decals and Safety Labels: While not mechanical, safety decals and operational labels are critical JLG parts. They can fade, peel, or become damaged, making important safety warnings or instructions illegible. Regular checks and replacements are necessary for compliance and operator safety.

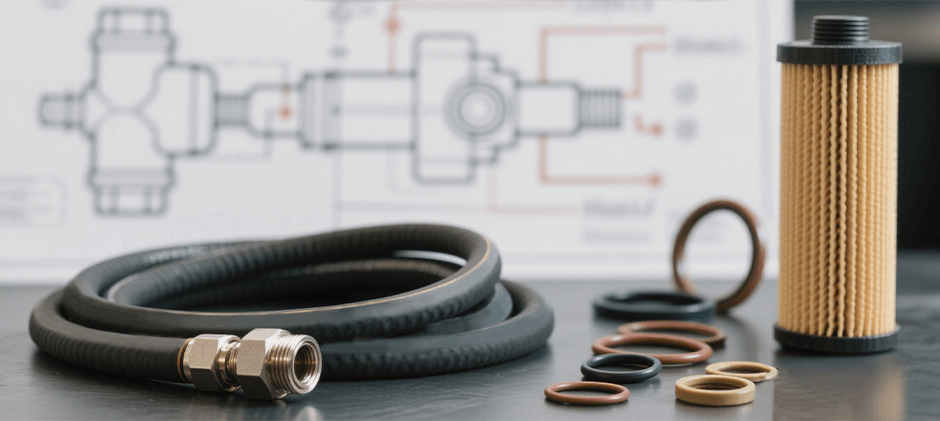

2. Hydraulic System Components – The Lifeblood of JLG Lifts

The hydraulic system is fundamental to the operation of any JLG lift, powering movements like lifting, extending, and steering. Hydraulic components are among the most common JLG parts needing attention.

- Hydraulic Hoses and Fittings: These are constantly under high pressure and subject to flexing and potential abrasion. Over time, hoses can develop cracks, bulges, or leaks, especially at fitting points. Regular inspection for wear and tear is essential.

- Rings and Seals: These small but mighty components are critical for preventing fluid leaks within hydraulic cylinders, valves, pumps, and motors. They can degrade due to age, temperature fluctuations, or exposure to hydraulic fluid, leading to leaks and reduced system efficiency.

- Hydraulic Filters: These are vital JLG maintenance parts. Hydraulic filters trap contaminants like dirt and metal particles within the hydraulic fluid, protecting sensitive hydraulic components from damage. They must be replaced at recommended intervals to maintain system cleanliness and performance.

- Hydraulic Pumps and Motors: While designed for durability, hydraulic pumps and motors can eventually wear out or fail, especially if the system has been contaminated or has run low on fluid. A charge pump, which ensures the main pump has adequate fluid, can also be a replacement item.

- Hydraulic Cylinders: Though the entire cylinder is not frequently replaced, seals within the cylinder are common. Rod damage can also necessitate repair or replacement.

3. Electrical System Components – Powering Precision and Control

Modern JLG lifts rely heavily on electrical systems for control, safety, and power (especially in electric models).

- Batteries: For electric JLG scissor lift parts and some hybrid or electric JLG boom lift parts, batteries are a consumable item with a finite lifespan. Their capacity diminishes over time and with charge cycles, eventually requiring replacement.

- Ignition Switches and Keys: Subject to frequent use, the ignition switch and associated keys can wear out, leading to starting problems.

- Joystick Controllers: As the primary operator interface for maneuvering the lift and platform, joystick controllers experience significant use. Internal electronic or mechanical components can wear down, leading to erratic operation or failure.

- Wiring Harnesses and Connectors: These can suffer from chafing due to vibration, corrosion in damp environments, or damage from impacts. Faulty wiring can cause a host of electrical issues, from intermittent operation to complete system failure.

- Sensors and Safety Switches: JLG lifts are equipped with numerous sensors and safety switches (e.g., limit switches, tilt sensors, load sensors, platform overload sensors). These are critical for safe operation and can malfunction due to damage, wear, or electrical faults. The control panel itself might also have switches or buttons that wear out.

4. Engine and Powertrain Parts (for Engine-Powered Models)

For JLG lifts powered by internal combustion engines, several engine-related JLG service parts are routinely replaced.

- Filters (Oil, Fuel, Air): Just like in any engine, these filters need regular replacement as part of routine JLG maintenance to ensure optimal engine performance and longevity.

- Spark Plugs (for gasoline engines) / Glow Plugs (for diesel engines): These are essential for ignition and require periodic replacement.

- Belts (Alternator, Fan, etc.): Rubber belts can crack, fray, or stretch over time and need to be replaced to prevent failure.

- Throttle Cable: On some models, the throttle cable can stretch, break, or become stiff, affecting engine response.

5. Platform and Structural Components

While major structural parts are robust, some platform-related items see frequent interaction.

- Foot Switches: Often used as an enabling device for platform operations, foot switches endure constant use and can wear out.

- Platform Control Box Components: Buttons, switches, and guards on the platform control panel can become damaged or worn.

What is the Frequency of Replacing Your JLG Parts? 5 Influential Factors

The frequency of replacing JLG lift replacement parts isn’t set in stone. It varies based on:

- Operating Environment: Dusty, corrosive, or extreme temperature environments accelerate wear.

- Usage Intensity: Higher operating hours and frequent heavy loads mean parts wear faster.

- Maintenance Practices: Following the manufacturer’s recommended JLG maintenance schedule and using maintenance kits or service kits can extend part life. Proactive replacement of worn parts prevents cascading failures.

- Age and Model of Equipment: Older machines or specific models might have parts that are known to wear more quickly.

How to Source Your JLG Lift Parts Effectively?

Finding the right JLG parts for sale quickly is important to minimize downtime.

- Identify the Correct Part: Use a JLG parts catalog or an online JLG parts lookup tool. Having your machine’s model and serial number is essential. JLG parts diagrams are invaluable for pinpointing the exact component.

- Choose a Supplier: Look for a JLG parts supplier with a broad inventory of common JLG parts, including both JLG scissor lift parts and JLG boom lift parts.

- Order Parts: Many suppliers allow you to order JLG parts online, offering convenience and often fast-shipping options.

Conclusion

Understanding the most commonly replaced JLG parts empowers operators and maintenance personnel to perform proactive maintenance, ensuring their JLG manlift and other access equipment remain safe, reliable, and productive. Regular inspections, timely replacement with quality parts, and a good understanding of your machine’s needs are key to maximizing its operational life and value.

At Fridayparts, we specialize in providing high-quality JLG aftermarket parts at affordable prices. With our vast inventory covering a wide range of JLG lift parts and components for many other heavy equipment brands, we are here to help you keep your machinery in top condition. If you need to source reliable JLG replacement parts, explore our selection or contact us today. We’re here to help you stock the essential parts you need with fast-shipping options.