The Throttle Position Sensor (TPS) sends throttle position data to the ECM. It has moving mechanical and electrical parts that wear out easily, which will result in more repair costs. A faulty or broken TPS can cause all kinds of problems. Check out the bad throttle position sensor symptoms below to figure out if you need to replace the sensor on your equipment, plus how to fix, replace or reprogram it.

What Is a Throttle Position Sensor & How Does it Work?

The throttle position sensor (TPS) is mounted on the throttle body of the engine. Tell the ECM how wide the throttle valve is open, that is, how much air is coming into the engine now. When you press the accelerator pedal or push the lever, the throttle opens, allowing a little more air to enter. TPS will pass this change to ECM right away. The way it works is pretty intuitive to understand:

- At idle, the throttle valve is basically closed. TPS sends a low-voltage signal, about 0.5 volts.

- When refueling, the throttle valve opens wider and wider. The voltage of TPS also increases.

- The accelerator is pressed to the bottom and the throttle is fully opened. TPS will emit the highest voltage signal, usually around 4.5 volts.

This real-time data is particularly critical. ECM combines the signal from TPS and data from other sensors to instantly calculate how much oil to spray and when to spray. Some systems also use this to determine the timing of transmission shifts. TPS is indispensable for fast engine response and fuel-saving operation.

Common Throttle Position Sensor Symptoms

A faulty TPS sends wrong or jumpy data to the ECM. The ECM then makes bad calls based on this bad info, and that causes all sorts of obvious performance problems. Some of these signs might also mean other issues, but if you’re dealing with several of them at once, a bad throttle position sensor is probably the culprit.

Check Engine Light or Fault Code Alert

A failing TPS will make the ECM store a Diagnostic Trouble Code (DTC) and turn on the warning light on your dashboard. Codes linked to the TPS circuit—like “Circuit Low Input”, “Circuit High Input”, or “Correlation/Rationality” errors (such as P0121, P0122, P0123)—point straight to the sensor or its wiring.

Engine Hesitation or Lack of Power

When you try to accelerate or put the machine under load (like lifting a heavy bucket of dirt), does the engine bog down, hesitate, or feel totally powerless? That’s a classic sign. The ECM isn’t getting the right signal that you need more power, so it doesn’t inject enough fuel. The engine basically starves when it has to work the hardest.

Rough or Unstable Idle

A bad TPS can send a fluctuating signal even when the throttle is fully closed. The ECM tries to keep the idle steady, so it’s constantly adjusting the fuel and air mix. This makes the engine RPM spike up, drop down, or jump around erratically. A stable idle only happens when the ECM knows for sure the throttle is closed.

Poor Fuel Efficiency

If you’re refueling your equipment more often than usual, a bad TPS could be the reason. If the sensor falsely reports the throttle is open wider than it really is, the ECM will inject more fuel than the engine needs. This overly rich fuel mix doesn’t just waste diesel—it can cause other problems over time, too.

Hard, Late, or Erratic Shifting

On machines with powershift or even some advanced hydrostatic transmissions, the Transmission Control Module (TCM) uses TPS data to decide when to shift gears and how hard to shift. A faulty signal can lead to delayed, rough, or unpredictable shifts because the transmission can’t correctly tell the engine’s load or what the operator is trying to do.

Sudden Power Surges or Black Smoke

The flip side of hesitation can happen, too. The sensor might suddenly send a high-voltage signal, tricking the ECM into thinking you’ve floored the throttle. This can make the machine lurch forward unexpectedly. That sudden, unnecessary burst of fuel often leads to incomplete combustion, which blows puffs of black smoke out the exhaust.

How to Test a Throttle Position Sensor?

The malfunction of the throttle position sensor is often similar to other engine problems. The most reliable way is to actually test it. Be sure to check the corresponding repair manual of the equipment. The operation method may be different for different brands and models. For example, Caterpillar, John Deere, and Komatsu have different details.

Read the Fault Code

Connect the diagnostic instrument suitable for heavy equipment to the diagnostic interface of the equipment and turn on the ignition switch to read the fault code. If you see codes like P0120 to P0124, you can basically tell that there is a problem with the TPS or related lines.

Take a Look First to See If There Are Any Obvious Problems

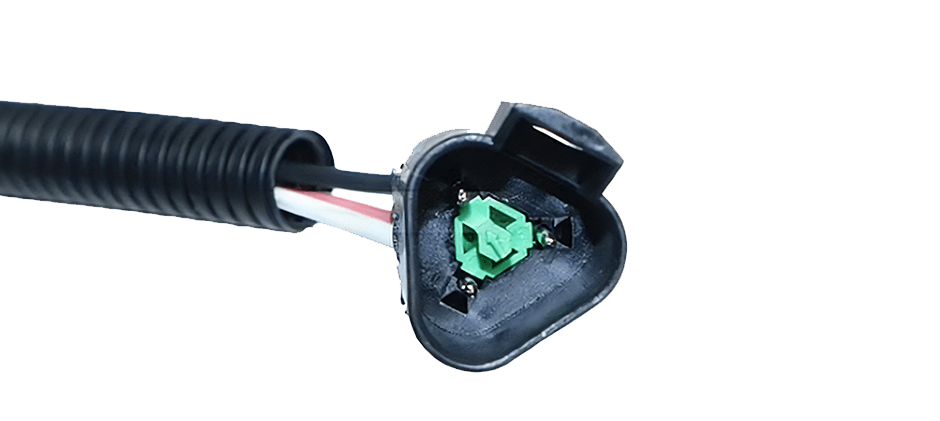

- Check if the plug of the TPS is loose. If it is not inserted firmly, it can easily cause an abnormal signal.

- Whether the pins in the plug are rusted or corroded, which is common in humid environments.

- Check the wiring harness for any abrasions or breaks. It is not uncommon to have problems with wiring harnesses under high-vibration working conditions, such as excavators and loaders.

- Verify whether the sensor body is cracked or loose on the throttle body.

Use a Multimeter to Confirm Whether TPS Is Normal

Turn the multimeter to the DC voltage level first, and do not unplug the TPS plug during testing. Instead, gently insert the watch pen from the back of the plug so that you can touch the metal terminal inside. The action must be light.

TPS generally has three wires. One is a 5-volt power supply, one is grounded, and the other is a signal line. Before the actual test, check with the manual to locate the signal line. Then turn the key to the ON, but do not start the engine. The red stylus is connected to the signal line, and the black stylus is connected to the negative terminal of the battery or the metal position on the engine.

The voltage is generally between 0.4 and 0.9 volts when the throttle is not moving. Slowly press the accelerator or push the throttle lever to its maximum. Normally, the voltage rises a little bit as the throttle opens. Approaching 4.5 volts at full opening.

The focus of the judgment is not a single number, but whether the voltage changes smoothly. As long as the voltage rises smoothly and does not suddenly fall to zero, TPS is basically good; if the voltage fluctuates, does not respond, or breaks down midway, there is a high probability that there is a problem with the sensor itself or the circuit, which requires further inspection or direct replacement.

Replacing the Throttle Position Sensor

If your tests confirm the TPS is bad, replacing it is easy to do.

- Get the right part: Get a good-quality replacement TPS that fits your machine’s brand, model, and engine.

- Disconnect the battery: For safety, always unhook the negative battery terminal first.

- Take off the old sensor: Unplug the electrical connector. Then remove the two screws or bolts holding the sensor to the throttle body. The old sensor should pop right off.

- Install the new sensor: Some techs suggest dabbing a tiny bit of anti-seize compound on the new sensor’s rotor tip—it’ll make removal easier next time. Mount the new sensor onto the throttle body and tighten the screws.

- Reconnect and test: Plug the electrical connector back in, then hook the battery back up.

- Calibrate if you need to: Start the engine. Some machines work fine right away. But some ECMs need a calibration or “relearn” process to recognize the new sensor’s baseline voltage. Sometimes this is as simple as turning the key on for 10 seconds before starting. Or you might need to follow a specific step from the service manual.

Conclusion

Preparing to DIY yourself or hire a local repair technician, paying attention to these symptoms can help you avoid expensive engine repairs and increased fuel consumption.

If the sensor fails, replace it immediately to avoid affecting other components. You can purchase the required sensor at FridayParts. All of our replacement parts are sold at very competitive prices, ensuring you get the best value for your money. We also guarantee fast and reliable delivery service.

FAQs

Can operating with a bad throttle position sensor cause damage to other parts?

Yes, something will definitely happen if this problem drags on for a long time. Although the equipment may not be broken immediately in a short period of time, it is easy to spend a lot of money repairing it if it is left alone. If the fuel is sprayed too much all the time, it will damage the exhaust system over time. For example, the DPF can be easily blocked or damaged. In addition, shifting is always messy and whether it should be changed or not will also cause the transmission to wear out in advance. Components that should have lasted a long time may need to be repaired or replaced early.

Can a bad throttle position sensor cause hard shifting?

Absolutely. This is one of the **most common TPS symptoms** on heavy equipment. The transmission control module depends a lot on the TPS signal to time shifts and set shift pressure. With bad data, the transmission is basically shifting blind. That’s why you get rough gear changes and poor machine performance.

What happens when you unplug a throttle position sensor?

Pulling out the throttle position sensor (TPS) will reduce the ECM’s most critical throttle signal. What happens next depends mainly on how the equipment’s program is set. Most equipment with a little bit of newness will have a fault light on immediately. Entering limp mode, engine speed and power are limited. At this time, if you press the accelerator again, the engine will either idle unsteadily, or even stall directly if it is serious.

In short, unplugging the TPS will not help you judge the problem, but will easily cause the equipment to not operate properly.

How often should I replace a throttle position sensor?

A TPS isn’t a regular maintenance part that you need to swap out on a schedule. It’s built tough to last thousands of hours. You only need to replace it if it fails a diagnostic test or if it’s clearly causing performance issues. That said, construction and farm equipment live in harsh, high-vibration environments. So TPS on these machines might fail sooner than it would on a regular car.