The serpentine belt drives key components on the engine, such as the alternator, water pump, and A/C compressor, and even powers some hydraulic accessories. They are made of reinforced natural and synthetic rubber. However, in high-load, dust, and mud environments, problems such as wear, deviation, or loosening are still easy to occur. The result is all sorts of unwanted noise. In this guide, we’ll show you where the common serpentine belt noise comes from. And how to eliminate these sounds for a smoother, quieter operating experience.

What Is a Serpentine Belt?

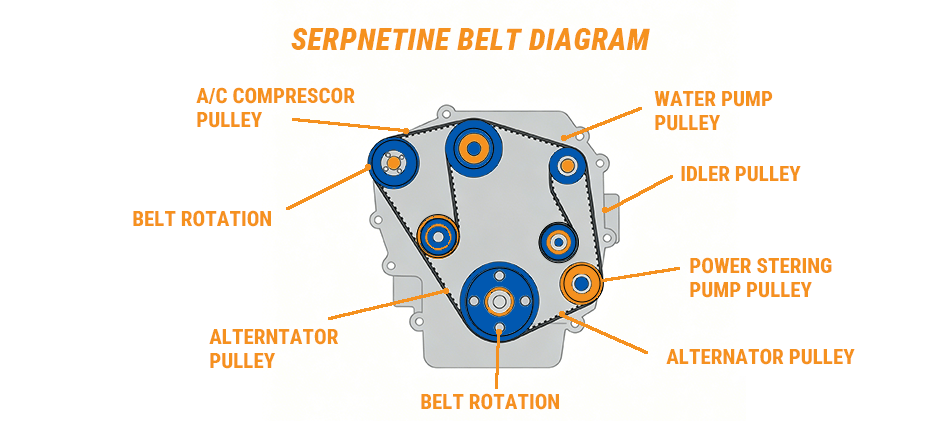

A serpentine belt is a single, continuous ribbed belt. It loops around many pulleys. Its job is to move power from the engine’s crankshaft to different vital parts. Older machines used lots of V-belts. But modern heavy equipment engines use just this tough single belt. It powers parts like these:

- Alternator: charges the battery and powers the electrical system

- Water pump: Circulates coolant to prevent engine overheating

- A/C compressor: Make the cab air conditioning work properly

- Power steering pump: provides steering assistance

- Hydraulic pumps: drive certain auxiliary hydraulic functions

The single belt construction is simple and efficient, but the disadvantages are also obvious—whenever there is a problem with the belt, these systems will stop together. You’ll lose power. The engine will overheat fast. The battery won’t charge anymore. And your entire operations will grind to a halt. Therefore, it’s better to pay attention to the condition of the serpentine belt. Once you hear unusual sounds or notice wear, check and deal with them.

The Most Common Serpentine Belt Noises

When the serpentine belt is a problem, the machine usually makes two sounds: a short chirp sound or a continuous squeal sound. Sounds a bit like it, but tends to represent a different kind of malfunction. It helps to find the problem faster by first distinguishing which one it is.

- Short chirp sounds: These are short, sharp sounds that come down at once, usually intermittently.

- Sustained squeal sound: The sound is sharper and longer and can last for several seconds. This sound tends to be more noticeable when the engine speed increases.

Reasons for Serpentine Belt Noise

Let’s figure out the usual causes of these two different noises. know what’s causing the sound, you can find exactly which part needs to be fixed.

Reasons for the Chirp

The chirping sound is mostly related to the belt running off track. The ribs of the belt do not fall exactly into the grooves of the pulley. There may be a chirping sound with each turn. Common causes of serpentine belt chirp include:

- Pulley Misalignment: If pulleys of the alternator, water pump, or others aren’t lined up right, the belt will run off-kilter. When a bracket’s bent, parts are installed wrong, or components are worn out, it usually happens.

- Worn Belt Ribs: Over time, the rubber ribs on the belt get hard, smooth out, or crack. They can’t grip the pulley grooves anymore. A little belt slip is what causes that chirping noise.

- Faulty Pulley Bearings: When bearings in idler pulleys, tensioner pulleys, or alternators get loose or worn, the pulleys will wobble. This throws the belt way out of alignment, and you’ll hear a non-stop chirp.

Reasons for the Squeal

A squeal is a classic sound of belt slippage. It’s the sound of the belt sliding over a pulley instead of gripping it, just like a tire spinning on ice. Top causes of a serpentine belt squeal:

- Low Belt Tension: A loose belt slips when under load. The belt stretched out with age. Weak/failing tensioner (internal spring loses strength). Wrong belt installed (too long).

- High Accessory Drag: If a bearing in parts like the water pump or A/C compressor starts seizing, it’s hard to turn. The crankshaft pulley forces the belt to spin, making the belt slip and squeal loudly.

- Fluid Contamination: Fluids on the belt kill friction, just like with chirping.When the system is under load (e.g., A/C kicks on), the slippery belt slips and squeals.

How to Fix Serpentine Belt Noise?

Before you check anything, turn the engine completely off. Take out the key. Let the engine cool down fully. Never work near the belt or pulleys when the engine is running.

Visual Check

Take a good, close look at the serpentine belt. Check for cracks, shiny ribbed surfaces—we call that glazing—frayed edges, or fluid stains. If you spot any of these signs of wear or damage, replace the belt straight away.

Water Spray Test (Quick Diagnostic Trick)

Run the engine while the noise is happening. Spray a little water on the ribbed side of the belt.

- If the noise is a chirp and it stops for a few seconds, it’s almost definitely pulley misalignment. The water acts as a quick, temporary lubricant.

- If the noise is a squeal and it gets louder, it’s a tension problem for sure. The water makes the belt even more slippery, so it slips worse.

Check the Tensioner

Most automatic tensioners have a wear mark. If the tensioner arm has moved past that mark, it’s worn out. Use a wrench on the pulley bolt to test the spring tension. The arm should move smoothly and feel firm. If it’s loose, weak, or jerky when you move it, replace the whole tensioner assembly.

Check Pulley Alignment

Grab a long straight edge (like a metal ruler). Lay it across the faces of two or more pulleys. It should sit flat against every pulley with no gaps. A gap means the pulleys are misaligned. For super-precise checks, pros use laser alignment tools.

Inspect All Pulleys

You need to remove the serpentine belt first to do this right. Once the belt is off, spin each pulley by hand (idler, tensioner, alternator, etc.).They should spin freely and quietly.

- If a pulley feels rough, grinds, or wobbles side to side, its bearing is bad.

- If it’s an idler or tensioner pulley, replace the part.

- If it’s an accessory (like a water pump or alternator), the whole unit needs repair or replacement.

Never use belt dressing spray or similar products to quiet a noisy belt. These are just temporary fixes that hide the real problem. They also attract dirt and make the belt wear out faster, leading to bigger failures later on.

Conclusion

Regular inspection can detect belt problems early and avoid sudden equipment failure during work. Normally, just notice if there are any abnormal sounds on the machine. Once something is wrong, you need to deal with it in time. Make the running smooth. When you need to replace parts like serpentine belts, FridayParts is your trusted choice. With 100,000+ parts in stock, you can always find the right accessories for your vehicle here.