When your excavator arm won’t lift or your dozer blade gets stuck, the entire operation grinds to a halt. Often, the problem lies with a powerful component: the hydraulic cylinder. In heavy construction equipment, Cylinders are everywhere. A failure means immediate downtime.

Whether you’re looking for a better understanding of hydraulic cylinders or a cylinder solution for your machine, this is the solution for you. Read on for our brief overview of what hydraulic cylinders are, how they work, and their essential components.

What is a Hydraulic Cylinder?

A hydraulic cylinder is a mechanical actuator that converts the energy stored in pressurized hydraulic fluid into powerful linear motion—a straight-line push or pull force. While your machine’s engine and tracks get it from point A to B, hydraulic cylinders do the heavy lifting. They are the muscles of your off-road equipment.

Every time an excavator boom extends, a loader bucket tilts, or a backhoe’s stabilizer leg plants itself on the ground, that movement is driven by a hydraulic cylinder. On heavy machinery, these devices aren’t just simple push-pull tools. They need to be robust enough to move massive components. They also have to handle the immense weight of the materials lifted or pushed. Think of it this way: if hydraulic fluid is the blood of your machine, the hydraulic cylinder is the heart and muscle combined, turning pressure into productive work.

How Do Hydraulic Cylinders Work?

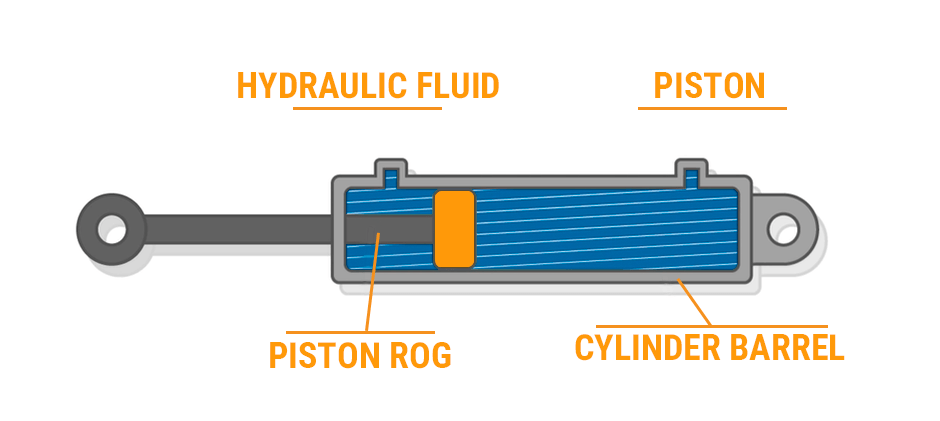

The principle behind a hydraulic cylinder is straightforward. It operates by using pressurized, non-compressible fluid (usually hydraulic oil) to move a piston back and forth inside a sealed tube.

The process works like this:

- A hydraulic pump, powered by the engine, sends a flow of hydraulic oil to the cylinder.

- This fluid enters a sealed chamber at one end of the cylinder, exerting immense pressure on the face of a piston.

- As the pressure builds, it forces the piston to move, which in turn pushes or pulls an attached piston rod.

- This linear movement of the rod is what controls the machine’s boom, arm, or bucket.

Most cylinders on off-road equipment are double-acting. This means we can direct hydraulic fluid to either side of the piston, which lets the piston move with power in both directions (extending and retracting). Single-acting cylinders, which rely on an external force like gravity to retract, are less common in heavy-duty applications.

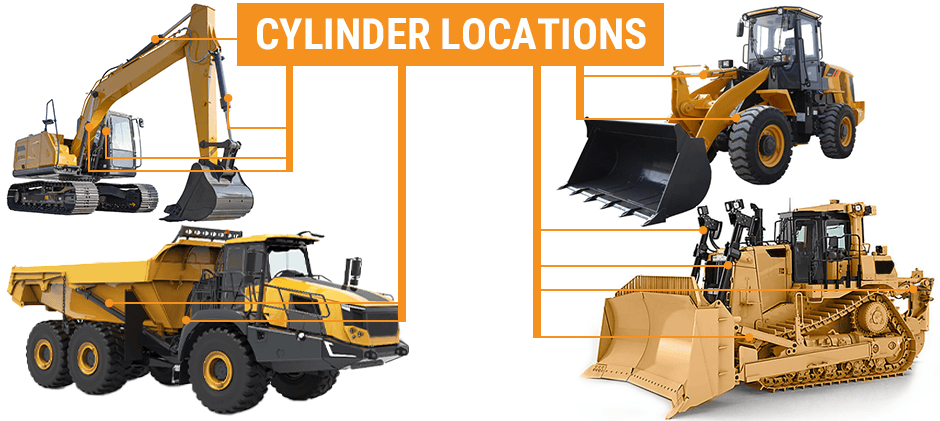

Where is the Hydraulic Cylinder Located on the Equipment Machine?

Look at any piece of off-road machinery, and you will find hydraulic cylinders everywhere. They are located at every point where a component needs to pivot, hinge, lift, or extend.

- On an Excavator: You will find large cylinders controlling the boom (the main arm connected to the machine), the stick (the dipper arm), and the bucket.

- On a Bulldozer: Cylinders lift and tilt the massive front blade and, on some models, control the rear ripper.

- On a Wheel Loader: You’ll see them managing the lift arms and tilting the bucket.

- On a Skid Steer: Compact but powerful cylinders operate the lift arms and attachments.

Now that we know how they generate force and where to find them, let’s break one down to its core components.

Identifying Hydraulic Cylinder Parts

A leak or a loss of power often points to a failure of an internal component. To effectively diagnose an issue and source the correct replacements, you must first be able to identify the core hydraulic cylinder parts. For almost any repair, you need to fully disassemble it, so you must know what you’re looking at.

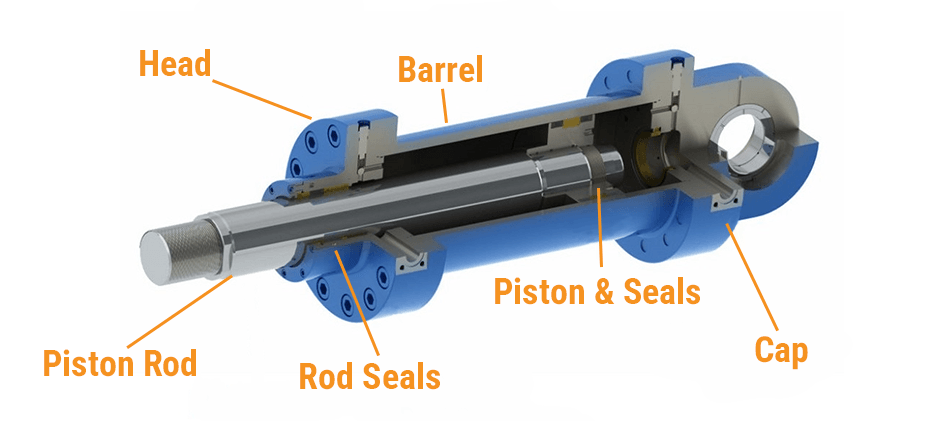

Cylinder Barrel

The cylinder barrel, a seamless and thick-walled tube, is the main body of the cylinder. Its function is to contain the high-pressure hydraulic fluid. The inside surface is honed to an extremely smooth finish. This smoothness is vital. It lets the piston seals create a tight seal without getting damaged as the piston moves.

In addition, there are two main types of barrels: single-action and double-action. The main difference between the two is that the double-action barrel has ports welded on both bases, while the single-action barrel has ports welded only at the end of the base.

Cylinder Head (End Cap)

The cylinder head, sometimes called the head cap, is the component that closes the barrel at the end from which the piston rod emerges. The main function of the cylinder head is to prevent pressure leakage in the pressure chambers at both ends of the cylinder, not just a simple cap. We precision-machine it to house the rod gland, rod seals, and a wiper seal. Usually, fasten it to the barrel using bolts, threads, or tie rods.

Piston

The piston is a cylindrical component fitted inside the barrel. Its job is to separate the two pressure zones within a double-acting cylinder. When high-pressure fluid pushes on one side of the piston, it slides through the barrel, creating the cylinder’s force. The piston is machined with grooves to hold a set of seals that prevent fluid from bypassing from one side to the other (a condition known as “blow-by”). Hydraulic cylinders retract or extend depending on the location of applied pressure relative to the piston.

Piston Rod

The piston rod is the hard, chrome-plated shaft that extends from the cylinder to connect to the machine’s linkage. It is typically made from high-strength, induction-hardened steel. The hard chrome plating is essential for two reasons: it provides an ultra-smooth surface for the rod seals to work against, and it offers excellent resistance to corrosion and physical damage from dirt and debris. A scratch or pit in the piston rod can quickly destroy the rod seals, causing a major leak.

Hydraulic Cylinder Base (Cap End)

The cylinder base or cap end is the closed end of the barrel, opposite the piston rod. It fully contains the pressure on one side of the piston. The base often has one of the cylinder’s main mounting points, like a welded cross-tube with bushings. You can pin this mounting point to the machine’s frame.

Rod Gland

The rod gland is the component that houses the critical set of seals at the rod end. It is often integrated into the cylinder head. Its primary purpose is to seal against the piston rod, preventing hydraulic fluid from leaking out of the cylinder. It also contains a wiper seal to scrape dirt and moisture off the rod as it retracts, protecting the entire system from contamination.

O-Rings and Seals

Seals are arguably the most critical and most frequently replaced components in a hydraulic cylinder. They may seem small, but a single failed seal can render a massive machine useless. There are several types, each with a specific job:

- Piston Seals: Located on the piston, they prevent fluid from leaking across the pressure zones inside the barrel.

- Rod Seals: Located in the rod gland, they prevent fluid from leaking out of the cylinder along the piston rod.

- Wiper Seals: The first line of defense, located at the outermost part of the rod gland. They clean the piston rod as it retracts into the cylinder.

- Wear Bands/Guide Rings: These are low-friction bands on the piston and in the rod gland that prevent metal-to-metal contact, guide the piston and rod, and absorb side loads.

- Static Seals (O-Rings): These are seals between non-moving parts, such as between the cylinder head and the barrel.

Repair Your Hydraulic Cylinder With Help from FridayParts

Knowing this information can help you determine the severity of the problem—whether a simple seal kit will solve the leak or a more complex repair is required. Of course, before any major operation, we always recommend seeking a professional evaluation to ensure an accurate diagnosis. Once you’ve identified the part that needs replacement, from a small seal to an entire hydraulic cylinder assembly, FridayParts has your back. You can view our complete line of cylinders here. By adopting proactive maintenance, you can minimize costly downtime.