The biggest thing about an excavator is that its upper body can spin a full 360 degrees right on the tracks. It’s this spinning ability that makes the machine so powerful and versatile. But have you ever wondered what makes this all possible? The answer is a key part called the slew bearing. Let’s take a look at what this part is, how it works, and how to maintain it.

What Components of a Slew Bearing?

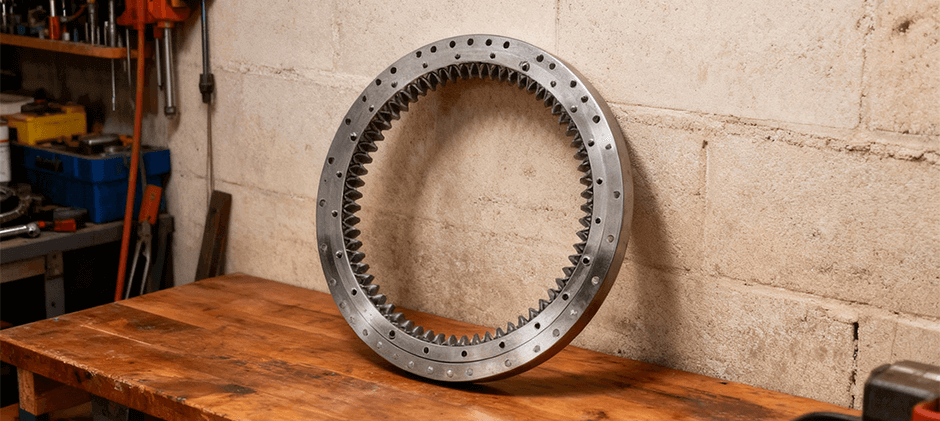

A slew bearing—also called a slewing ring or turntable bearing—might look like just a big, plain metal ring. But it’s actually a precision-built part. To really get how it works, you need to check out the components that team up to handle heavy forces.

- Inner & Outer Rings: The bearing’s base is two steel rings that fit one inside the other. On an excavator, one ring (usually the outer one) bolts to the undercarriage and stays put. The other ring (the inner one) bolts to the upper frame—we call that the “house”. The sides of these rings that face each other have specially cut grooves. These are what we call raceways.

- Rolling Elements: Tucked inside those raceways, between the two rings, are the rolling elements. Most of the time, these are hardened steel balls. But some heavy-duty versions use cylindrical rollers instead. Cut the friction down to next to nothing, so the two rings can slide past each other nice and smooth. The difference between the two? Balls make point contact, while rollers make line contact—this helps spread out heavier loads better.

- Seals: Tough seals sit on both the top and bottom of the slew bearing. These seals have two important jobs: First, they keep the vital lubricating grease inside the bearing. Second, and just as critical for off-road gear, keep dirt, water, sand, and rock dust out. A seal that goes bad is basically a one-way ticket to early bearing failure.

- Gear Teeth: On almost every excavator, one of the rings (usually the inner one) has gear teeth cut right into its edge. These teeth are what let the bearing spin when it’s powered.

One more thing worth mentioning: the swing drive. It’s a separate system, but it works directly with the slew bearing. The swing drive has a hydraulic motor and a gearbox that turns a small pinion gear. This pinion gear meshes with the teeth on the slew bearing, and that’s what gives the machine the force to rotate its upper house.

How Does a Slew Bearing Work?

The slew bearing is the critical rotating link between an excavator’s fixed undercarriage and its spinning upper body.

How it works is total mechanical magic. When the operator moves the joystick to swing the machine, hydraulic fluid fires up the swing drive motor. The motor spins the pinion gear, which locks onto the big gear on the slew bearing’s inner ring. As the pinion turns, it forces the inner ring (and the whole upper body attached to it) to spin around the stationary outer ring.

But the slew bearing does way more than just let the machine rotate. It’s a total load-carrying workhorse. It handles three types of forces all at the same time:

- Axial Load: The straight-down weight of everything on the upper body—the cab, engine, counterweight, boom, and arm.

- Radial Load: The side-to-side horizontal forces that kick in when the machine swings or digs off to one side.

- Tilting Moment: The massive twisting force that happens when the boom stretches out with a heavy load. This force tries to tip the upper body right off the undercarriage.

Slew bearings are built specifically to handle all these forces together. They keep the machine stable and the movement smooth. Without one, an excavator would just be a fixed digging tool that can’t turn at all.

What Causes a Slew Bearing to Wear or Fail?

Slew bearings work under crazy high stress. And on a rough construction site, a bunch of things can make them wear out and eventually break down. Knowing what causes this is the first step to preventing it.

Contamination

When the seals get worn or damaged, gritty stuff like dirt, sand, and water can get into the raceways. Once inside, this gunk mixes with the grease and turns into a grinding paste. This paste tears up the smooth surfaces of the rolling elements and raceways in no time.

Improper Lubrication

A slew bearing can fail if it doesn’t have enough grease—or if you use the wrong kind. Too little grease means metal rubs directly against metal. This creates tons of heat and makes the metal surfaces flake off—a problem we call spalling. Using grease that isn’t made for heavy-duty pressure is just as bad. It won’t form a good enough protective layer.

Overloading and Shock Loads

Every excavator has a lift chart for a reason. Lifting stuff heavier than the machine’s rated limit on a regular basis, or slamming the bucket into the ground hard, or dropping heavy loads—all of these hit the slew bearing with massive stress. This can create tiny dents in the raceways (we call this brinelling), and these dents turn into cracks and spalling later on.

Loose Bolts

The bolts holding the slew bearing to the upper and lower frames will stretch and loosen over time—all that vibration and constant load changes are to blame. If you don’t check these bolts regularly and tighten them to the manufacturer’s specs, the bearing will shift a tiny bit. This misalignment shoves the machine’s entire weight onto one small spot of the bearing, leading to quick, localized wear and a total breakdown before long.

The number one reason we see slew bearings fail early isn’t a bad part—it’s skipping regular greasing and bolt torque checks.

Signs a Slew Bearing is Worn or Damaged

A slew bearing that’s going bad will almost always give you warning signs before it totally breaks down. Learning to spot these signs when you do your daily walk-around checks can save you from a sudden breakdown on the job site.

- Grinding, popping, or clicking noises: When you swing the machine, listen closely. A steady grinding or rumbling sound usually means dirt got in or there’s not enough grease. A sharp click or pop? That might be a cracked raceway or damaged gear teeth.

- Too much play or “rocking”: As the bearing wears out, the gap between the inner and outer rings gets bigger. That makes it feel “loose.” Here’s how to check: have someone extend the boom and gently rock it up and down. You watch the gap between the house and the undercarriage. Any obvious up-and-down movement or rocking is a big red flag—your bearing is worn out.

- Metal shavings in the grease: When you grease the bearing regularly, pay attention to the old grease. The shiny metal flakes or bits are the inside parts of the bearing that are wearing down and shedding metal.

- Jerky or stuck rotation: If the machine’s swing feels rough, tight in some spots, or jerky, the rolling parts inside aren’t moving smoothly anymore. That could be from damage, dirt getting in, or uneven wear on the raceways.

Best Practices for Slew Bearing Maintenance

How long your excavator’s slew bearing lasts depends directly on how well you maintain it. Taking care of it proactively is way cheaper and less time-consuming than replacing it after it breaks. Follow these simple best practices to make this key part last as long as possible.

- Keep it greased properly, on a regular schedule: Grease the slew bearing according to the manual. Usually, every 50 to 100 hours of use. Use high-quality, extreme-pressure (EP) grease. Slowly rotate the machine while pumping grease into the fittings, until you see clean grease coming out of the seals. This makes sure the whole raceway is covered and flushes out old, dirty grease.

- Check bolt tightness regularly: Vibration and constant load changes will definitely make the mounting bolts loose over time. Use a calibrated torque wrench to check the slew bearing bolts at the intervals the manufacturer recommends (often every 250 or 500 hours). Tighten them to the specified torque in a crisscross pattern—this makes sure the clamping force is even.

- Keep the seals clean: Always wipe the area around the grease fittings and seals clean before greasing. Pumping grease through a dirty fitting is a guaranteed way to push dirt straight into the bearing’s core.

- Listen and check while operating: Make it a habit to listen for weird noises and check for too much play during your daily pre-operation inspection. Catching a problem early can mean the difference between a quick adjustment and a full replacement.

- Operate smoothly: Avoid slamming or shocking the machine. Move it smoothly and in a controlled way, and never exceed the machine’s load limit. Working on super uneven ground for a long time also puts lopsided stress on the bearing—try to level your work area when you can.

Wrapping Up

The slew bearing is the quiet workhorse that lets your machine spin smoothly and position precisely— it’s what makes heavy-duty construction and digging jobs doable. If you understand how slew bearings work, what causes them to wear out early, and how to take care of them, you’ll keep your machine running at its best and keep your operators safe. And if a slew bearing does go bad? Replace it as soon as you can. Otherwise, your excavator won’t work right. Luckily, at FridayParts, you can find good-quality, affordable excavator replacement parts easily.